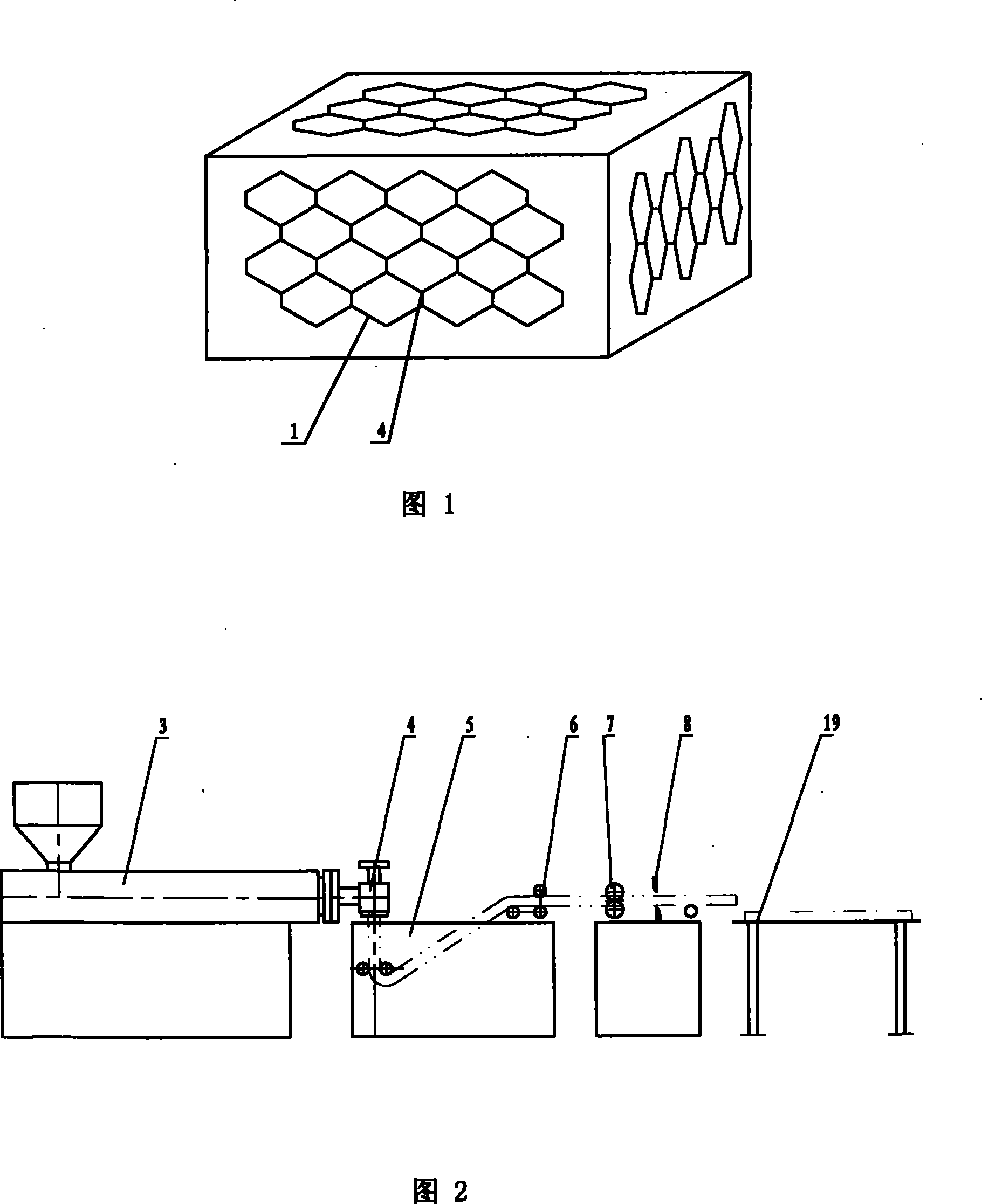

High elasticity netted plastic cushion, producing method and equipment thereof

A high elasticity and plastic technology, applied in spring mattresses, mattresses, stuffed cushions, etc., can solve the problem of air permeability uniformity, plastic thread bonding fastness and overall strength, disordered bonding points, and increased quality and other problems, to achieve the effect of solving uneven ventilation and weak overall strength, reducing production costs, and having no impact on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

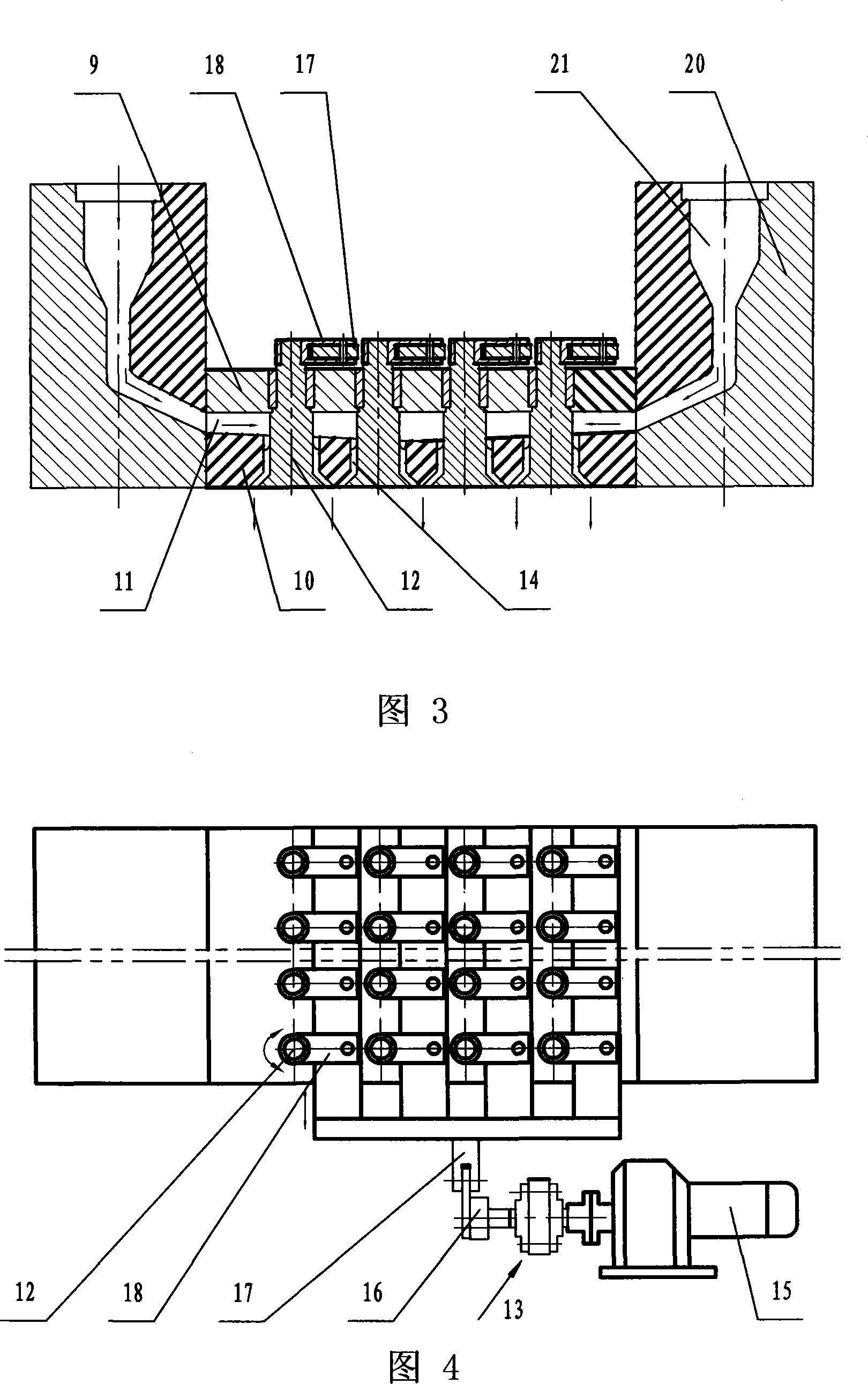

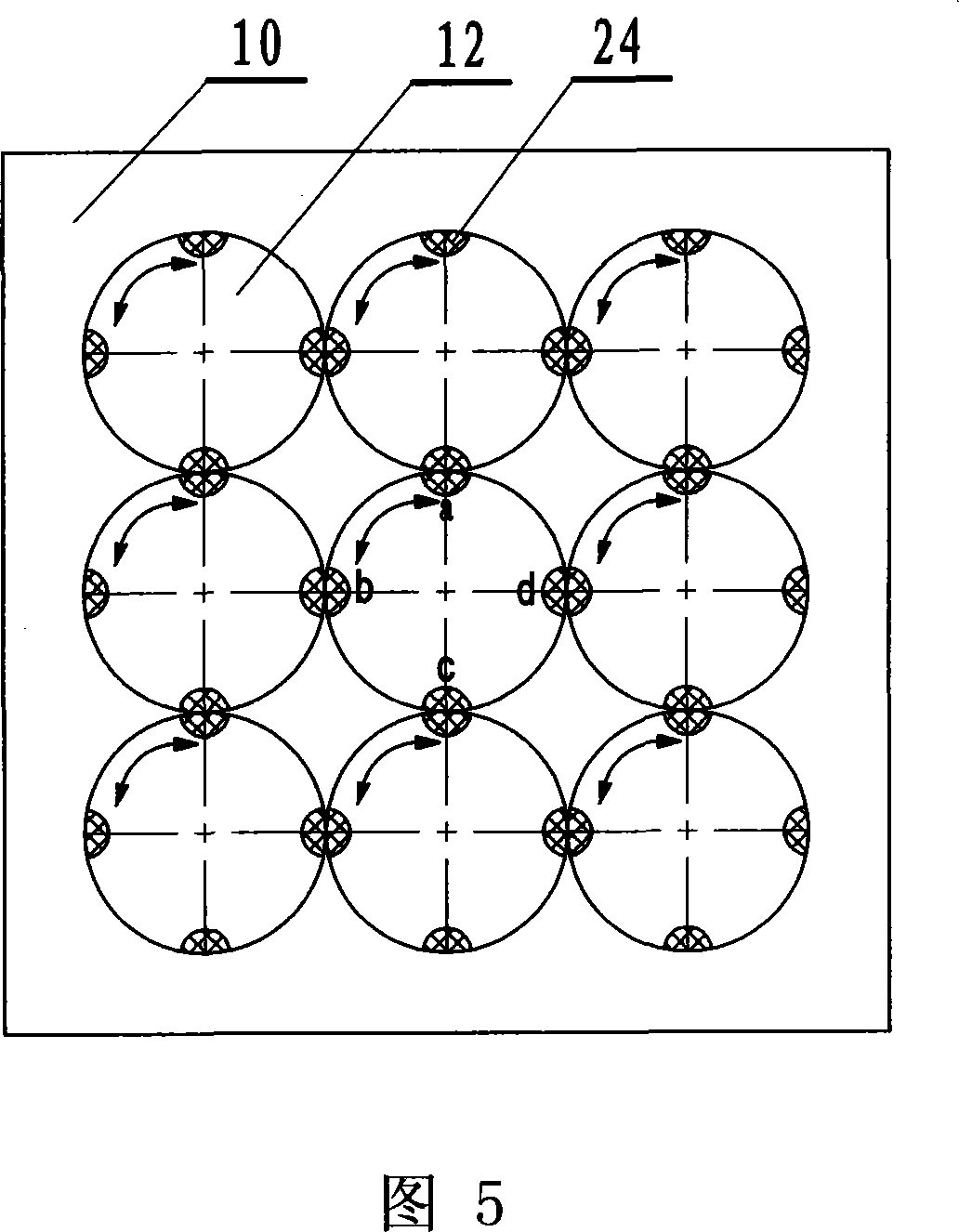

[0017] The production equipment of the product is shown in Figure 2, 3, and 4: There are plastic extruder 3, plastic wire mat molding die 4, cooling setting device 5, traction device 6, trimming device 7, cutting device 8 and product bracket 19 Among them, the plastic extruder 3, the cooling setting device 5, the traction device 6, the edge trimming device 7, the cutting device 8 and the product carrier 19 are all existing technologies. The plastic wire mat forming mold 4 is provided with upper and lower fixed templates 9, 10 fixedly connected to the feeding die 20, and a transverse material channel 11 is arranged between the upper and lower fixed templates 9, 10, and the material channel 11 is connected to the feeding die. The material channel 21 in 20 communicates, and a plurality of rotating mold cores 12 vertically penetrate the upper and lower fixed templates 9, 10 and are arranged in rows and rows on the same plane; the rotating mold core 12 is connected with the upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com