A control method for a dry closet for a ship

A control method and technology of drying wardrobes, applied in the field of control, can solve the problems of clothing deformation, lack of drying parameters and air temperature and humidity monitoring and control functions, and inability to effectively discharge heat, so as to shorten the drying time and reduce the drying time. Energy consumption and the effect of prolonging the service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

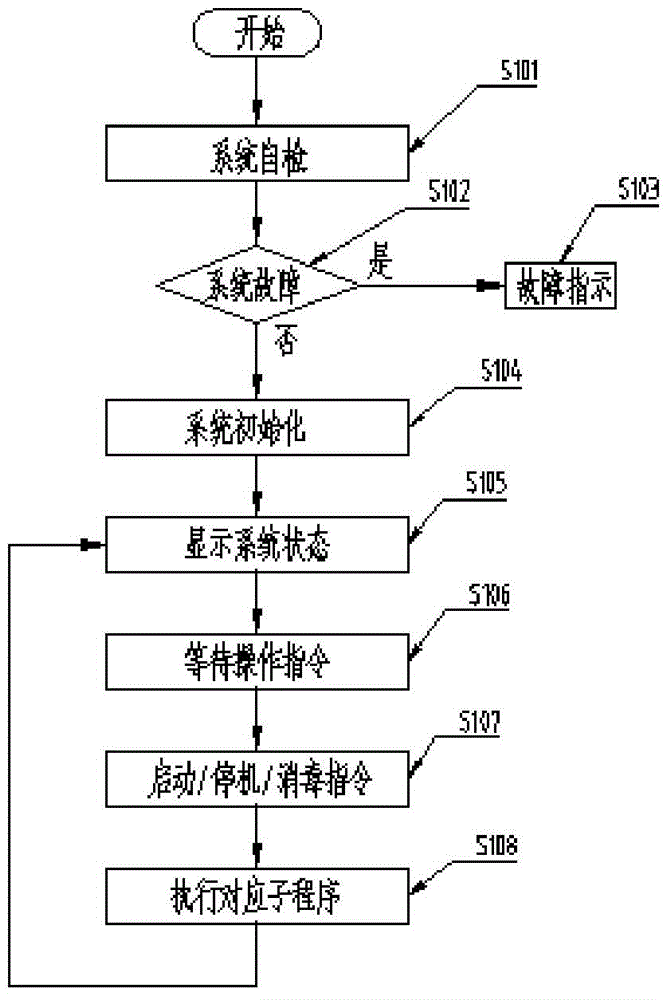

[0064] A control system and control method for a marine dry closet of the present invention will be further described in detail below in conjunction with the accompanying drawings.

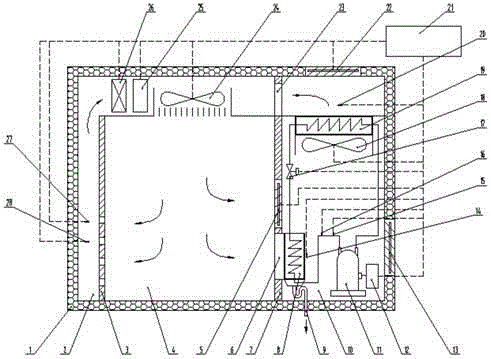

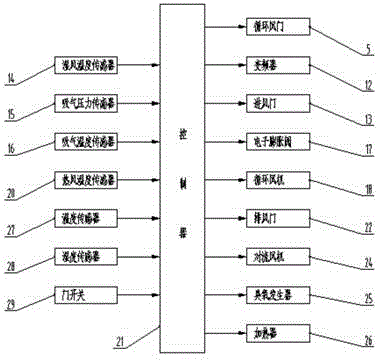

[0065] as attached figure 1 with figure 2 As shown, it is a kind of marine dry wardrobe, which consists of a cabinet body 1, a convection return air duct 2, a back panel 3, a clothes hanging room 4, a circulation damper 5, a dehumidification air outlet 6, a compartment plate 7, an evaporator 8, and a drain pipe 9. Machine compartment 10, compressor 11, frequency converter 12, air intake door 13, wet air temperature sensor 14, suction pressure sensor 15, suction temperature sensor 16, electronic expansion valve 17, circulation fan 18, condenser 19, hot air A temperature sensor 20, a controller 21, an exhaust door 22, a hot air outlet 23, a convection fan 24, an ozone generator 25, a heater 26, a temperature sensor 27, and a humidity sensor 28 form. Wherein the cabinet body 1 is fixed on the hull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com