Window blind rotation sub-mechanism and timing control slider system comprising same

A shutter and slider technology, applied in the direction of windows/doors, building components, building structures, etc., can solve the problems of limited rotation angle, the outer diameter of the roll cannot be reduced, and the shape of the top rail of the shutter is bloated. Motion control for sophisticated and compact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Such as image 3As shown, a blind turning sub-mechanism includes a shell formed by fastening a base 38 and a top cover 39. The shell is longitudinally penetrated by the hexagonal prism-shaped main driving shaft 2 of the blind. The gear clutch 34, the front cable slider 361 of the ladder belt, the front and rear cable slider drive screw 363, and the rear cable slider 362 of the ladder belt through which the shaft 2 penetrates. The hollow front and rear cable slider drive screw 363 is in transmission connection with the gear clutch 34. The slider driving screw 363 is provided with two threaded sections with opposite helical directions, and a short smooth axial surface is arranged between the two threaded sections, and the near gear clutch end of the front and rear cable slider driving screw 363 is provided with a round tenon . The front cable slider 361 of the ladder belt and the rear cable slider 362 of the ladder belt are respectively threaded on the two thread segment...

Embodiment 2

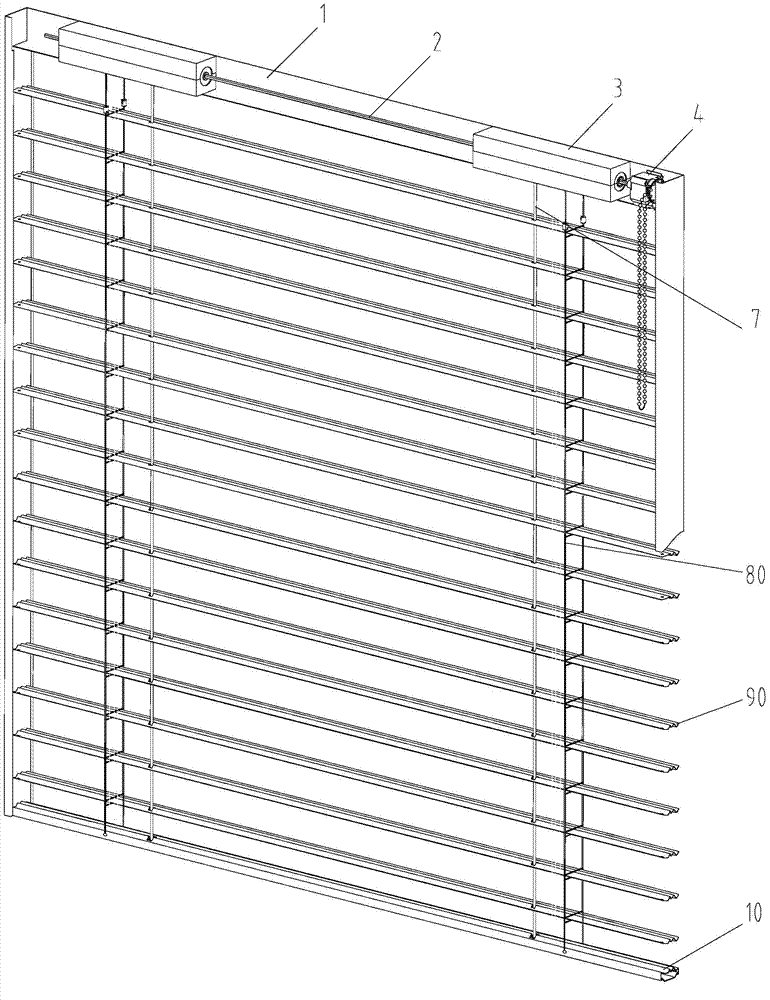

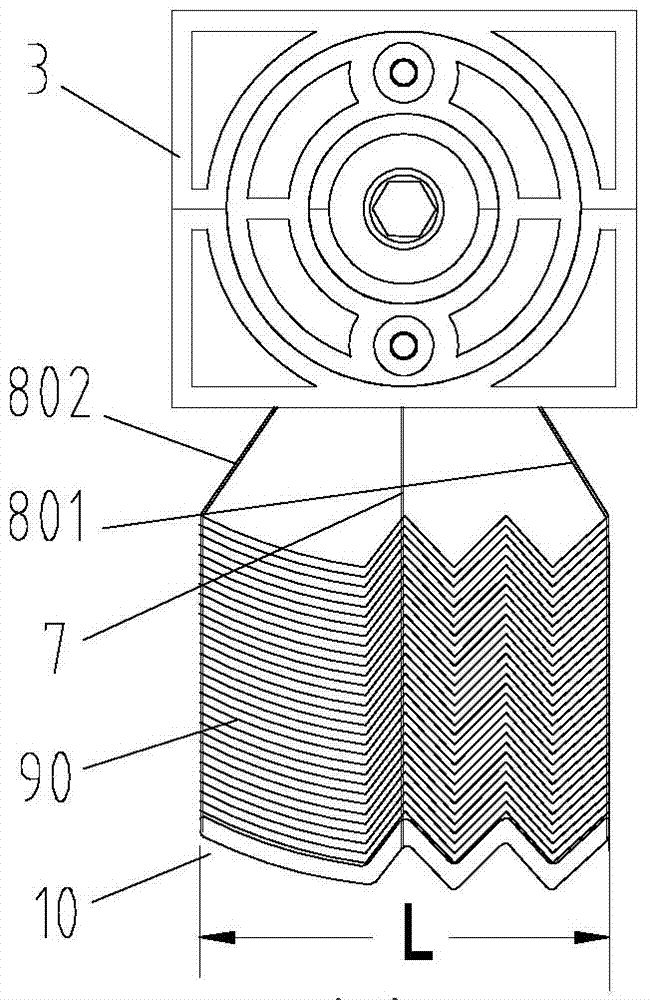

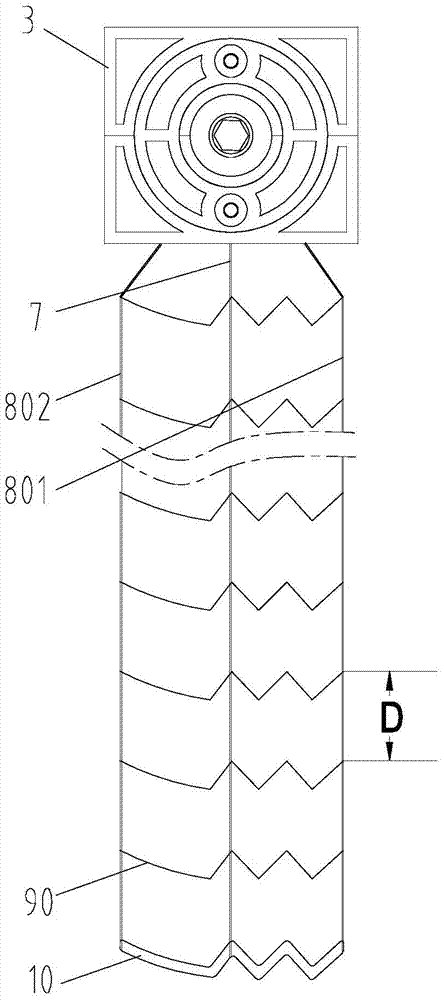

[0070] A time-sequence control slider system including the louver turning sub-mechanism of the present invention is used to control the overall retraction and the turning of the louver blades of the fixed-pitch louver. figure 1 It shows the three-dimensional diagram of the fixed-pitch shutter when it is unfolded. The fixed-pitch shutter is composed of the top rail 1, the shutter transmission mechanism, the lifting rope 7, the main ladder belt 80, the shutter blades 90 and the bottom rail 10. The shutter transmission mechanism is composed of a hexagonal column The total drive shaft 2, the slider system 3 and the driver 4 are composed, Figure 2 shows the cross-sectional view of the fixed pitch shutter in three states, Figure 2a A cross-sectional view of fixed pitch shutter louvers 90 raised and folded is shown, Figure 2b shows a cross-sectional view of the fixed-pitch shutter louvers 90 lowered and unfolded, Figure 2c Shows the cross-sectional view of the fixed-pitch louv...

Embodiment 3

[0075] A time-sequence control slider system 3 including the louver turning sub-mechanism of the present invention is used to control the overall retraction and the turning of the louver blades of the three-time quarter-variable-pitch louver. Figure 16 It shows the three-dimensional diagram when the three-time four-point variable-pitch shutter is unfolded. The three-time four-point variable-pitch shutter is composed of a top rail 1, a shutter transmission mechanism, a lifting rope 7, a main ladder belt 80, a second ladder belt 81, and a second ladder belt 82. The second third ladder belt 83, the main louver blade 90, the second 100 blade 91, the second 200 blade 92, the second 300 blade 93 and the bottom rail 10; System 3 and driver 4 are composed.

[0076] Figure 17 shows a schematic diagram of the unit-combined louver cross-section of the three-time quarter-variable pitch louver, where only the main louver 90, the second 100th blade 91, the second 200th louver 92, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com