Large-caliber high-pressure pressure regulating valve for pneumatic test device

A pneumatic test, large-diameter technology, applied in the field of high-pressure pressure regulating valves, can solve the problems of difficulty in meeting the requirements of wind tunnels or test benches, low pressure regulation accuracy, and small adjustment range, and achieves good pressure regulation characteristics and pressure regulation. The effect of high precision and wide voltage regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention will be described in detail below in conjunction with the accompanying drawings.

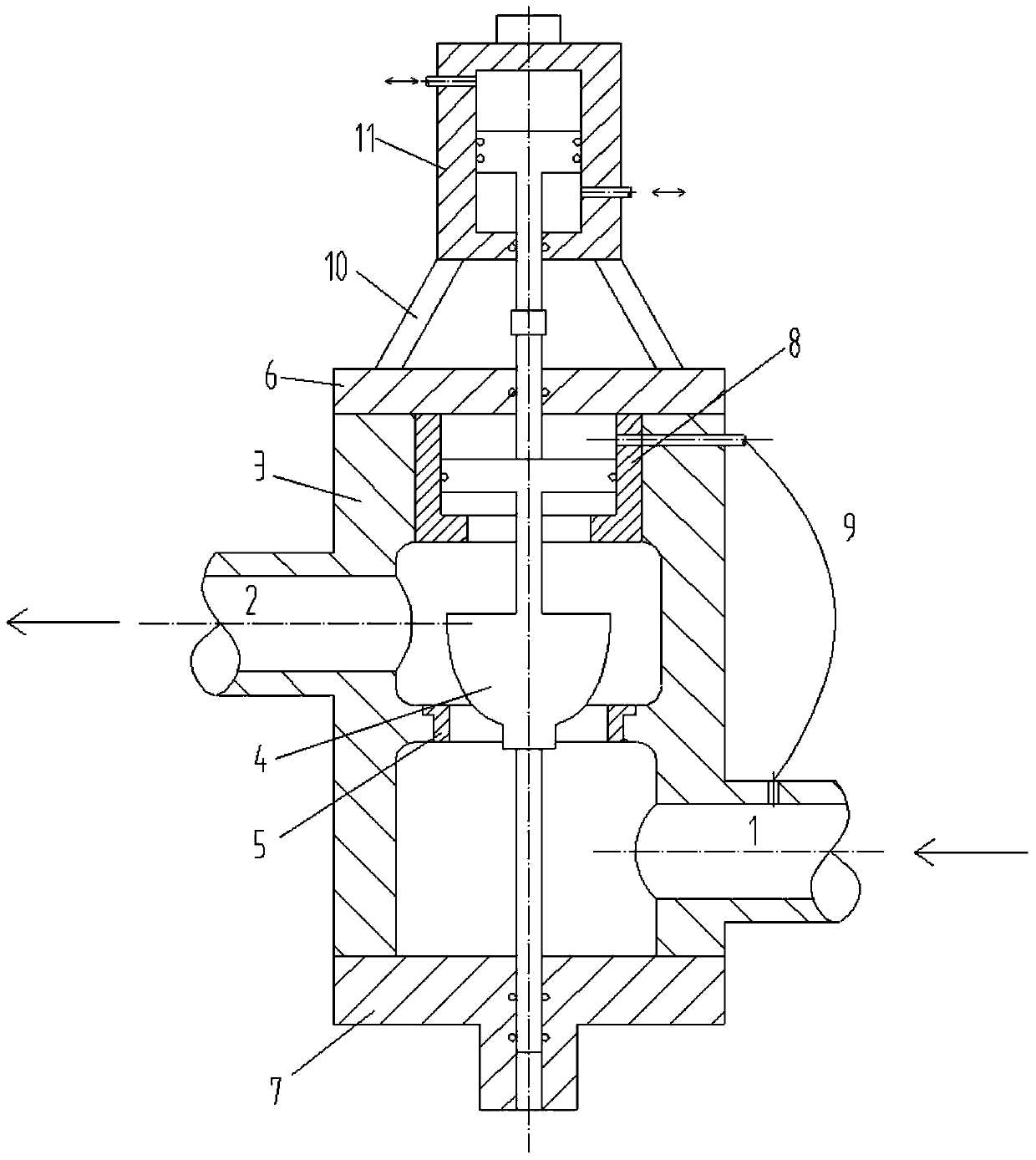

[0024] like figure 1 As shown, the present invention provides a large-diameter high-pressure pressure regulating valve for pneumatic test equipment. The structure of the high-pressure pressure regulating valve adopts the form of a plunger valve, including: an air inlet 1, an air outlet 2, a valve body 3, and a valve core 4. Valve seat 5, upper cylinder head 6, lower cylinder head 7, balance cylinder 8, balance air pipe 9, cylinder bracket 10, drive cylinder 11, drive cylinder rod 31, connecting nut 32;

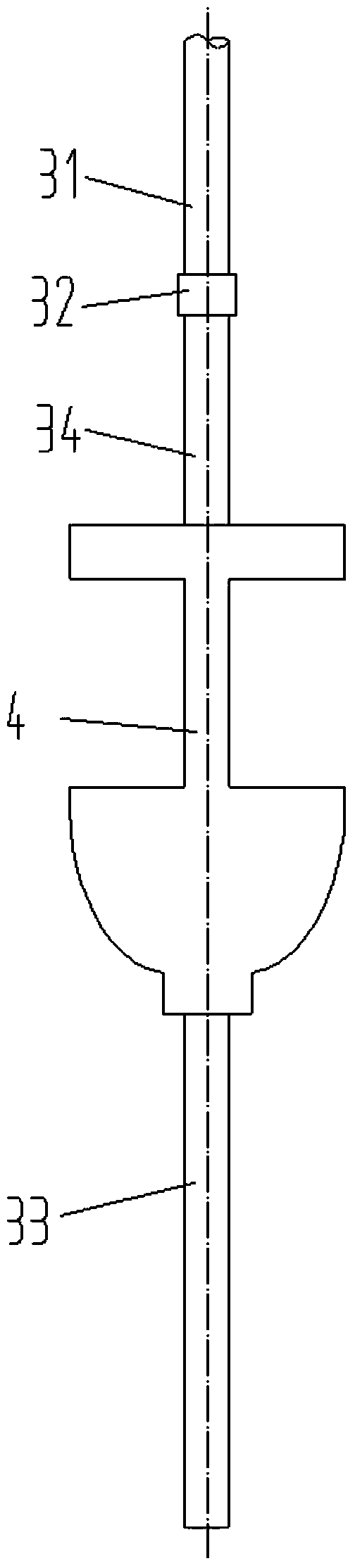

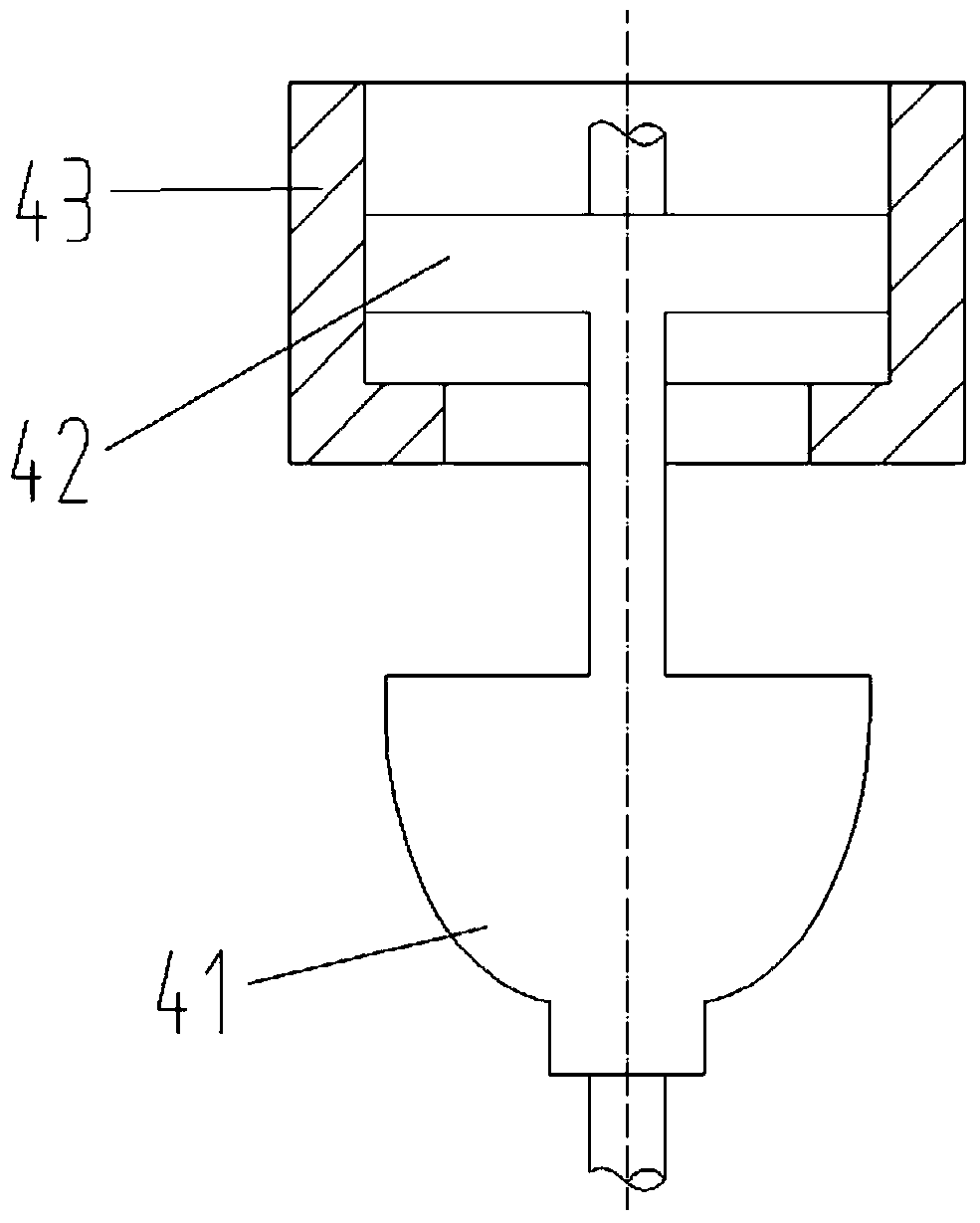

[0025] like figure 2 As shown, the spool 4 includes a guide rod 33, a profile section 41, a balance cylinder piston 42 and an upper strut 34; one end of the guide rod 33 is fixedly connected to the bottom of the profile section 41, and the top of the profile section 41 passes through the balance cylinder The piston 42 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com