Grain weighing device

A weighing device and grain technology, which is applied in the direction of measuring device, weighing, automatic feeding/discharging weighing equipment, etc., can solve the problems of low work efficiency and achieve low labor intensity, simple structure and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

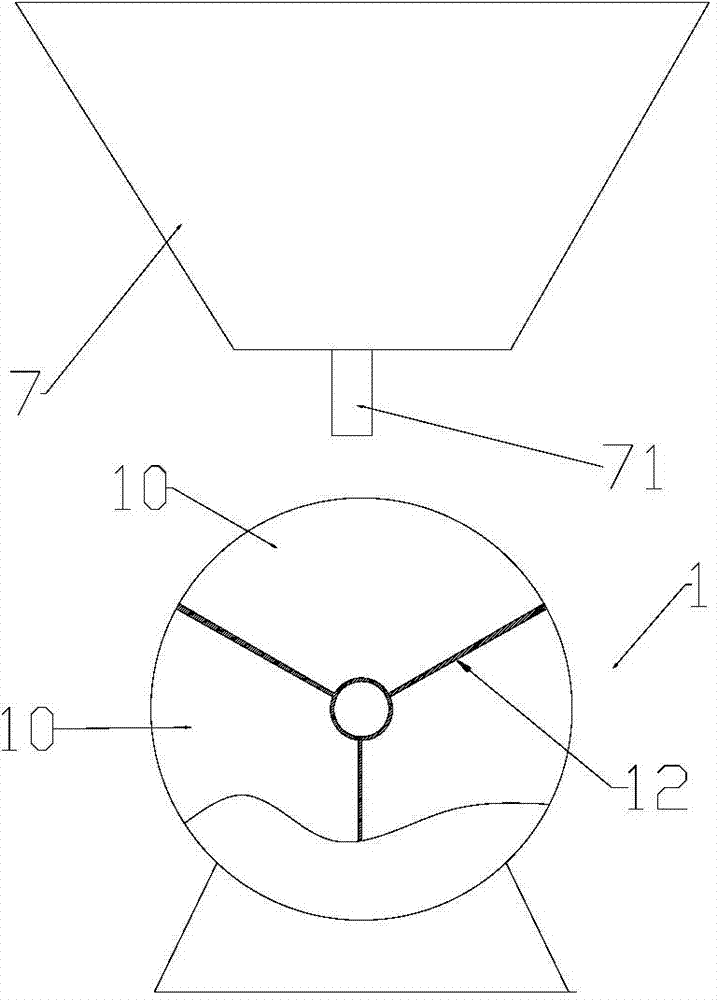

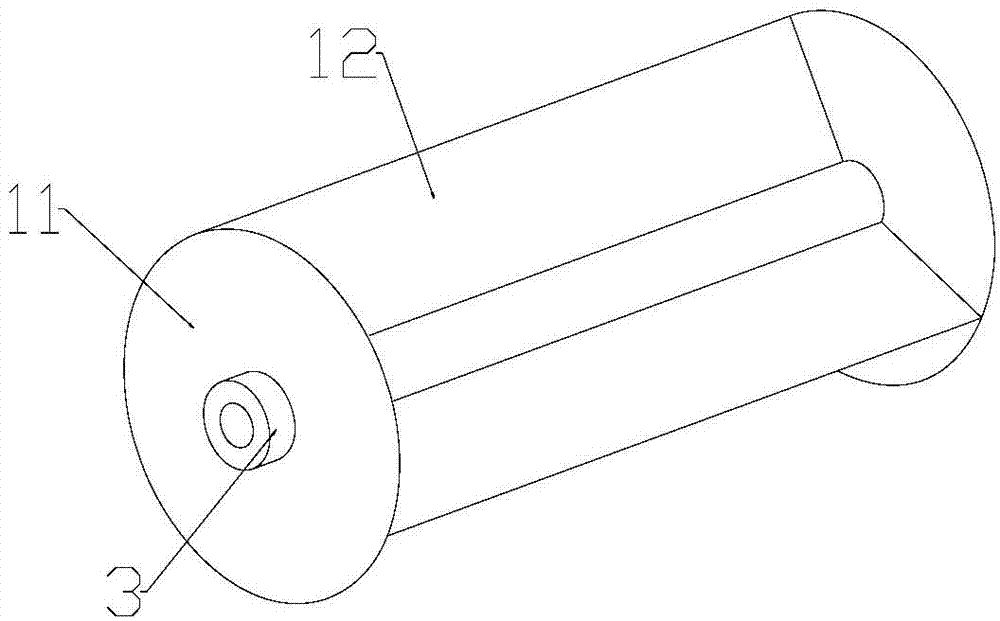

[0011] In the grain weighing device of the present invention, a discharge port is provided below the grain storage bin 7, and the discharge port 71 discharges the grain into the weighing bucket 1, and the weighing bucket 1 has an axisymmetric structure as a whole, and the axis of symmetry is in the horizontal direction. 1 There is a circular side plate 11 on the left and right, and three baffles 12 are arranged between the two side plates 11. The adjacent two baffles 12 and the left and right side plates 11 form a distribution hopper, and the center of the weighing bucket 1 is set A horizontal shaft hole through which the rotating shaft passes. Bearings are provided at both ends of the rotating shaft, and a sensor is supported below it. The sensor is connected to a digital processing device and a display to measure the weight change of the hopper. The weighing hopper 1 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com