Exhaust electron testing system and method for a dielectric protective film material

A technology of dielectric protective film and escaping electrons, applied in measuring devices, measuring electrical variables, measuring current/voltage, etc., can solve the problems of expensive equipment, affecting the accuracy of test results, and large ambient current noise, and reduce the difficulty of testing. , Eliminate adverse effects, and apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

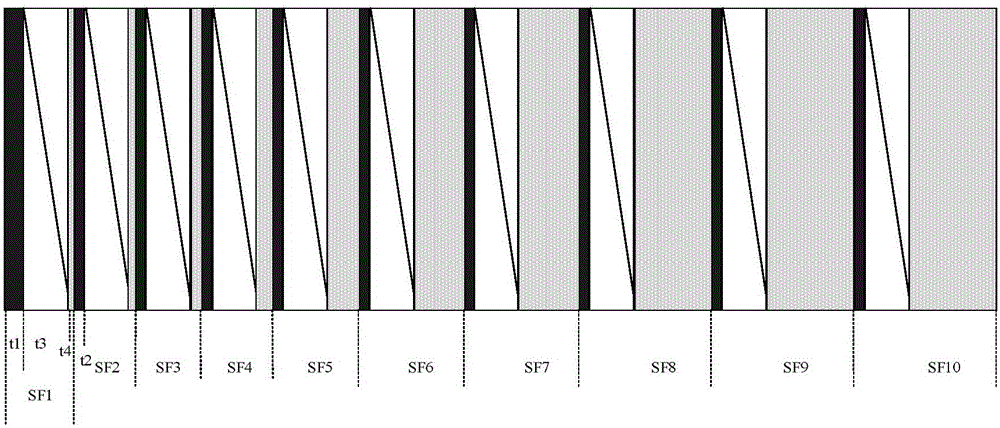

[0052] A method for testing the escaped electrons of a dielectric protective film material of the present invention, such as Figure 5 As shown, it includes at least one cycle period T for testing, and the cycle period T includes the following voltage application periods carried out successively in sequence,

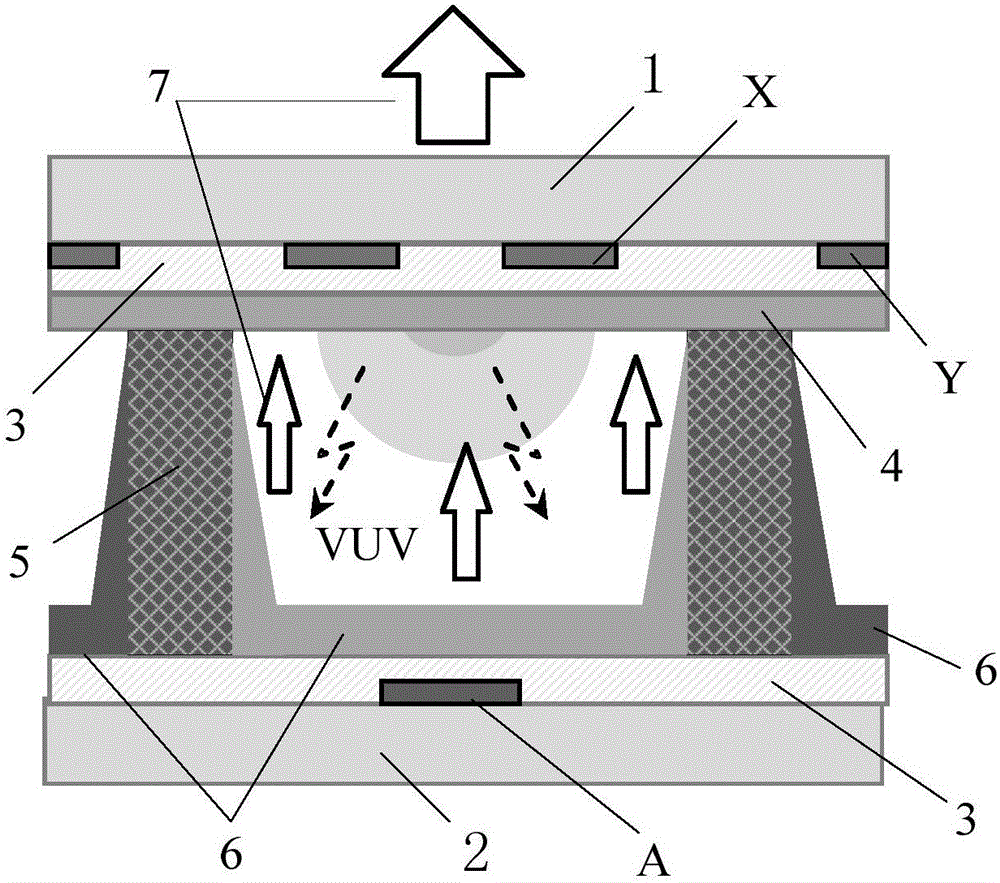

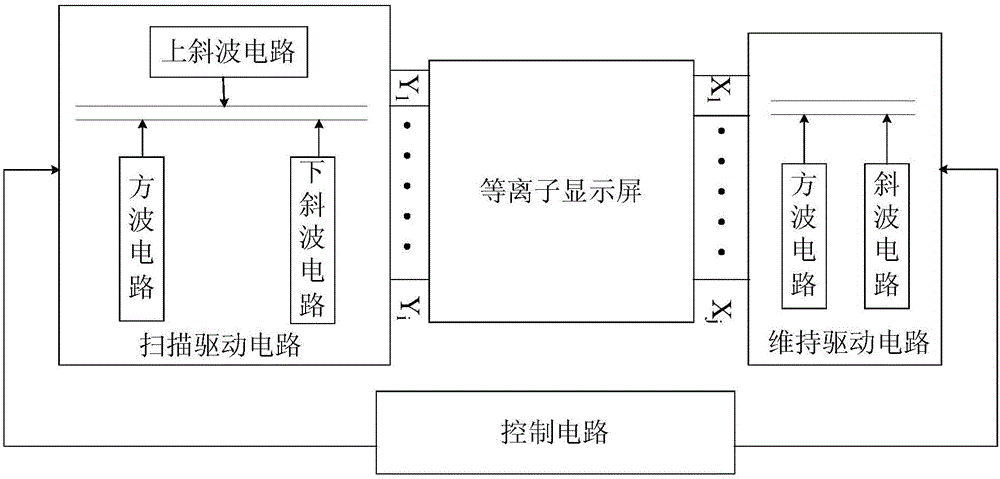

[0053] 1) Excitation period T s ; Alternately apply at least one discharge period T on the sustain electrode X and scan electrode Y of the plasma display screen under test c The excitation voltage, during a discharge cycle T c The internal working gas completes at least one discharge process; the excitation voltage is not less than the ignition voltage V required for the discharge of the working gas in the plasma display screen under test f ; Thus, a VUV gas discharge for exciting ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com