Socket assembly

A composite and sleeve technology, applied in hand-held tools, wrenches, wrenches, etc., can solve the problems of lower structural strength of the sleeve, scratches on aluminum rings, inability to apply aluminum ring disassembly operations, etc., to save manufacturing costs , good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Regarding the technology, means and effects adopted by the present invention, three preferred embodiments are given and described in detail below with drawings, which are for illustration purposes only, and are not limited by this structure in the patent application.

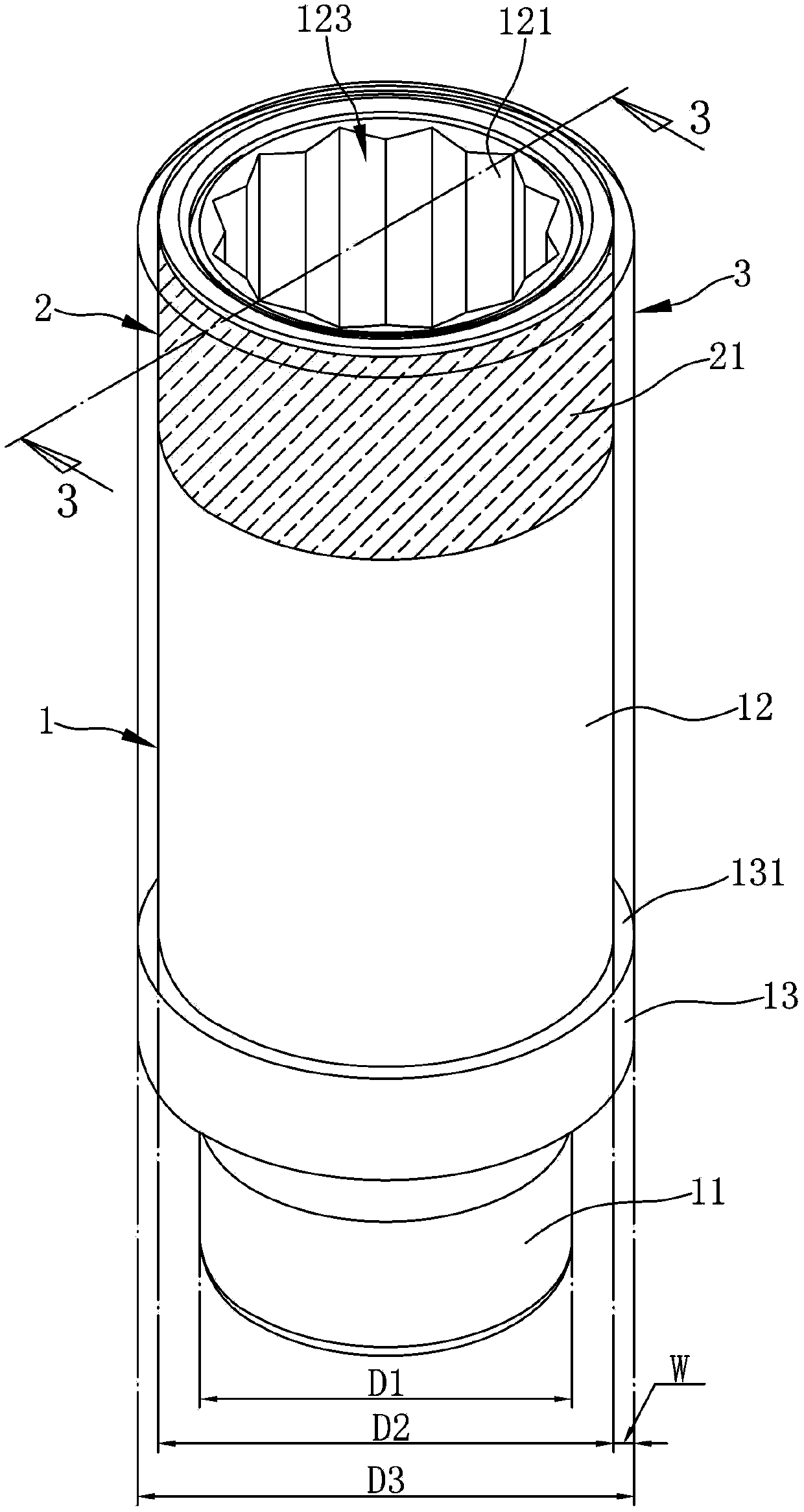

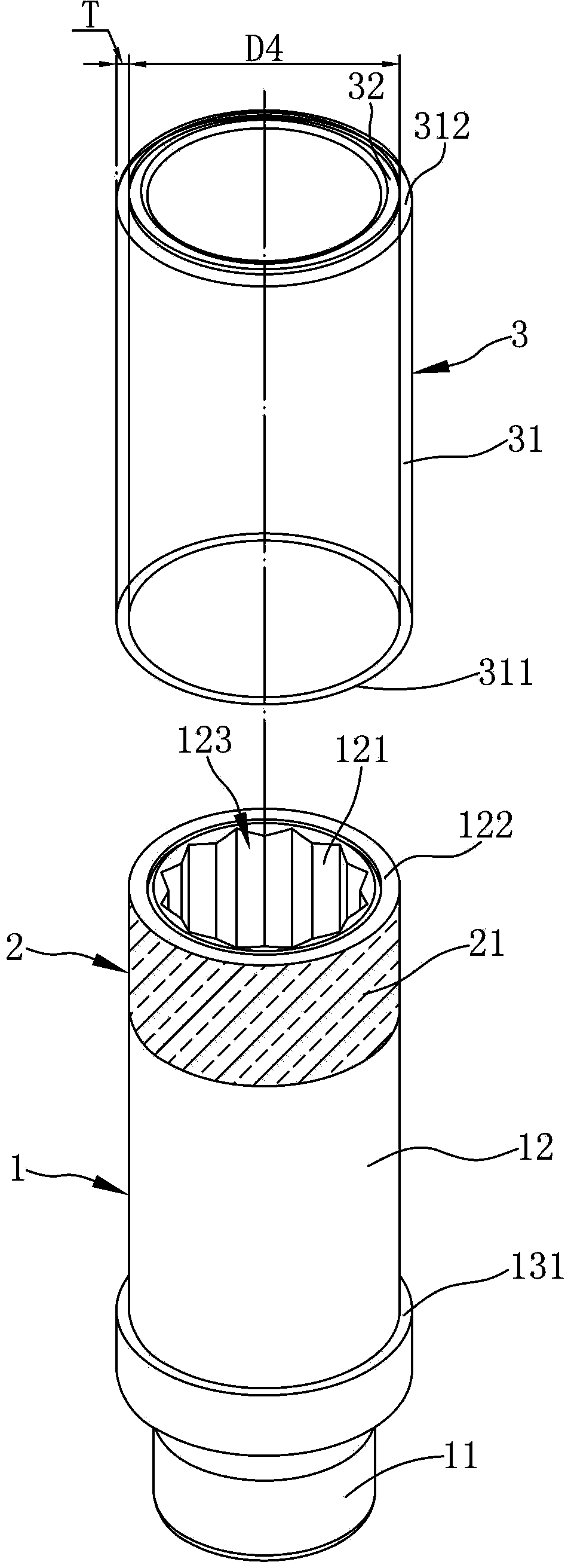

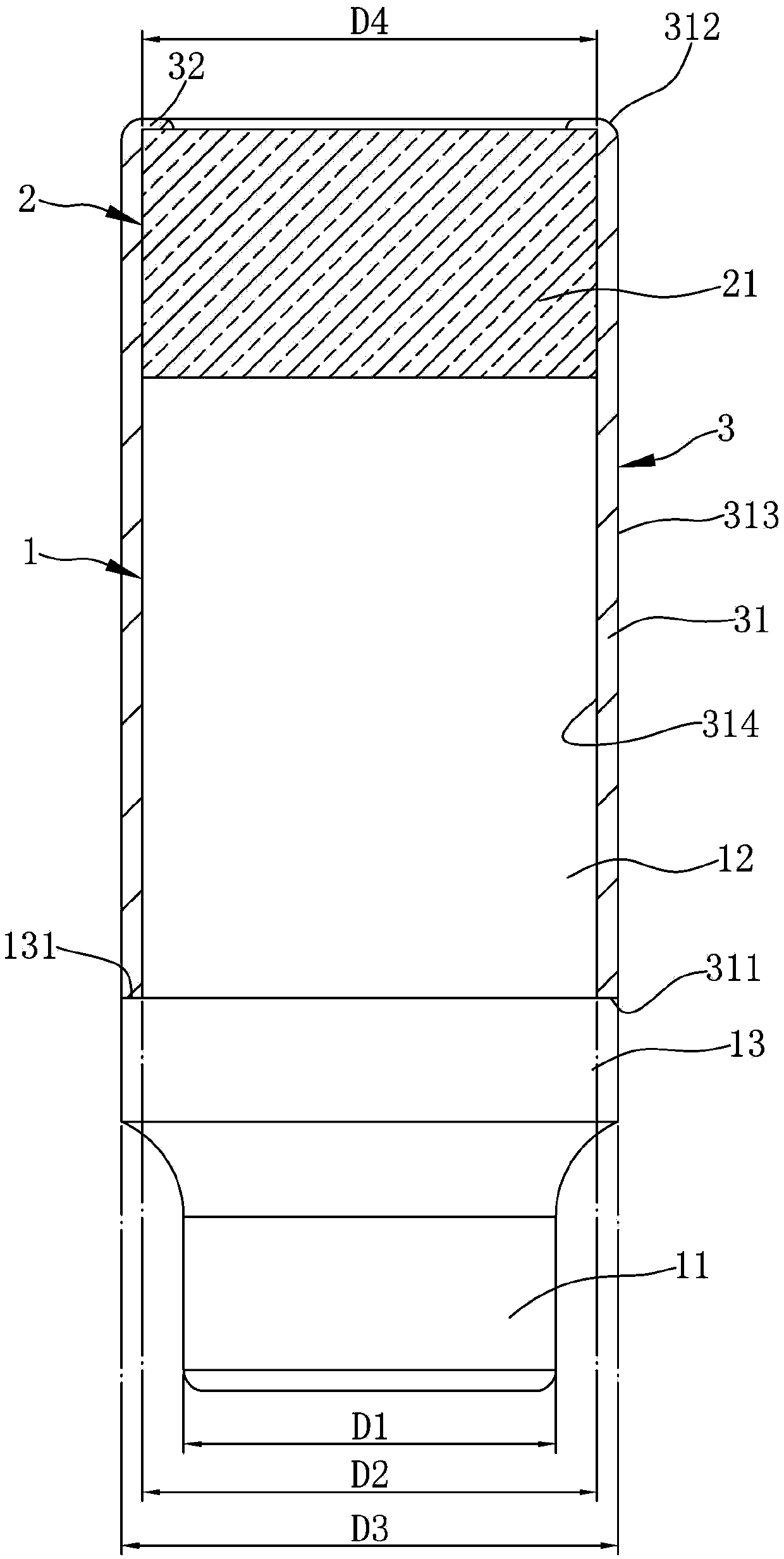

[0035] Please refer to Figure 1 to Figure 3 , is the three-dimensional appearance view, three-dimensional exploded view and cross-sectional view of the first embodiment of the composite sleeve of the present invention. The composite sleeve of the present invention can be respectively connected with a driving tool and a fixing part (not shown in the figure), the driving tool can be a wrench, an air tool, an electric tool or an automatic machine, and the fixing part can be a screw or a nut ...and other components of fixed objects. The sleeve includes a body 1, a socket 2 and a bushing 3; wherein, one end of the body 1 is connected to one end of the socket 2, and the bush 3 is sleeved between the body 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com