Modular search and rescue robot with reconfigurable function

A modular, robotic technology, applied in the field of search and rescue robots, can solve problems such as poor expansion capability, limited search and rescue robot functions, and configuration of search and rescue functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

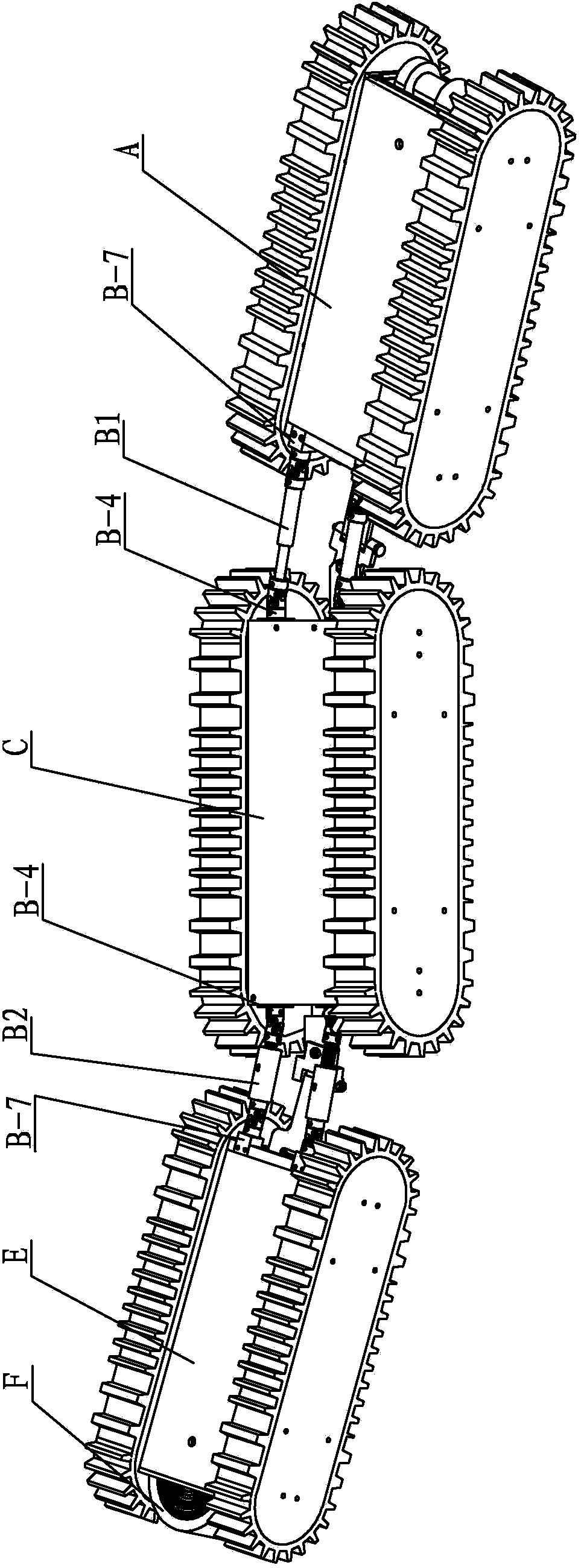

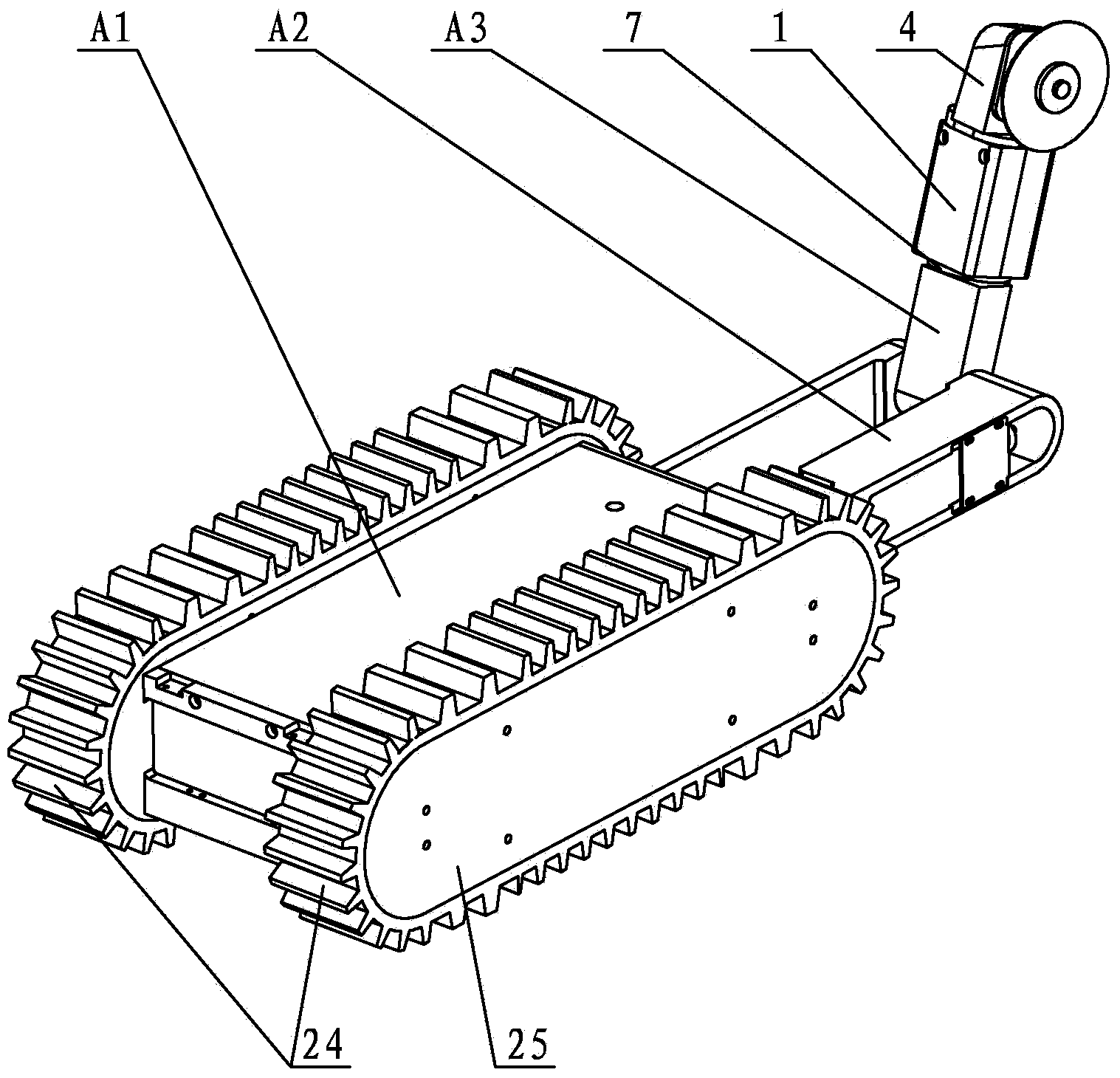

[0023] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 7 and Figure 8 This embodiment is described. The functionally reconfigurable modular search and rescue robot of this embodiment includes a first operation module A, a first connection module B1 and a mobile module C. The first operation module A includes a mobile trolley A1, a mobile telescopic mechanism A2 and The cutting mechanism A3 is hinged on the telescopic mechanism A2, the mobile module C and the mobile trolley A1 both include a car body 21 and a car body moving part D, and the car body moving part D is installed on the car body 21, and the car body 21 is a rectangular box with an opening 21-1 at one end. The mobile module C is connected to the mobile car A1 through the first connection module B1, that is, the opening 21-1 of the car shell 21 on the mobile module C faces outward, and the mobile car A1 The opening 21-1 of the car body 21 faces outward, the first connecting pi...

specific Embodiment approach 2

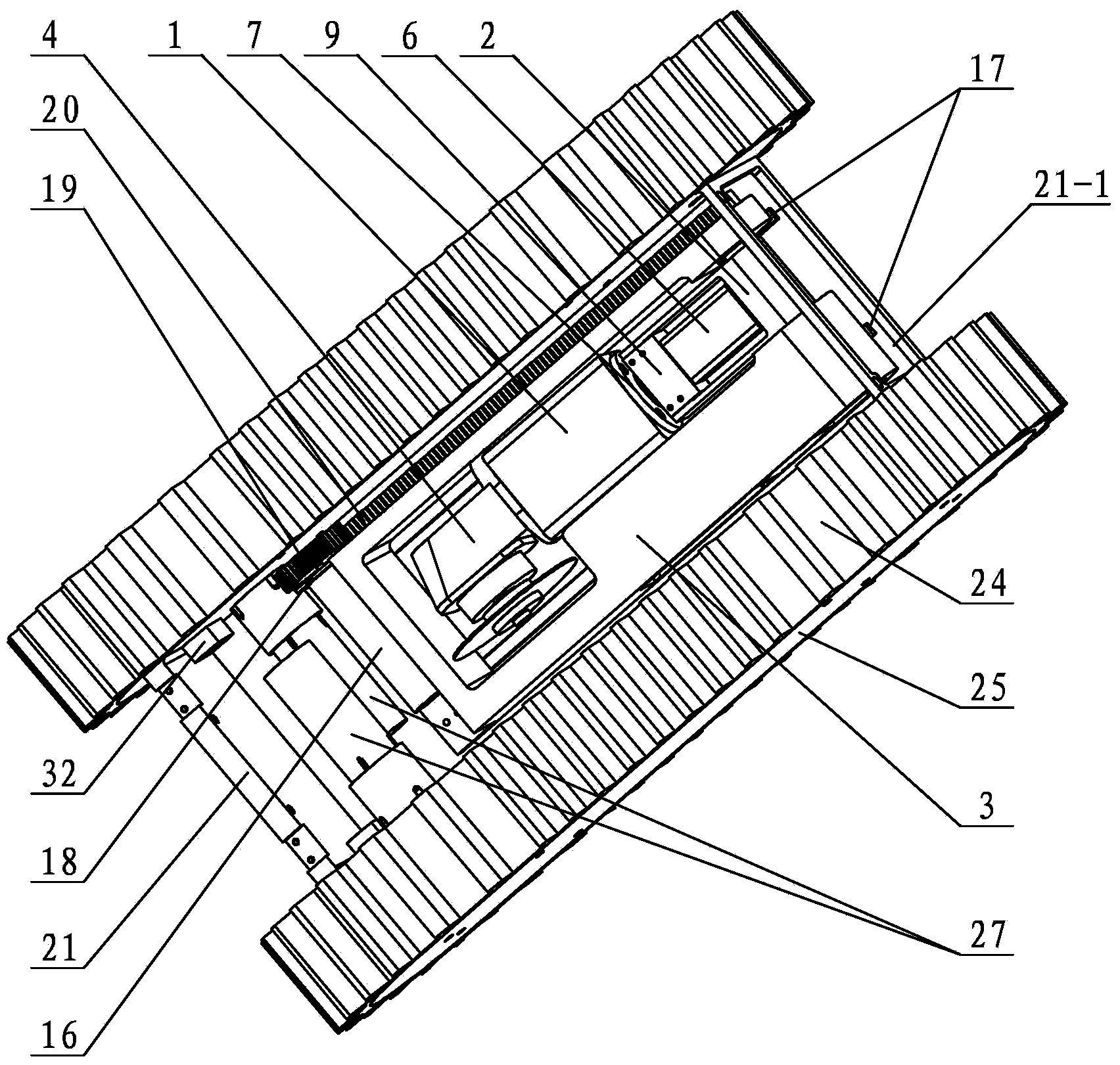

[0024] Specific implementation mode two: combination Figure 2 to Figure 5 Describe this embodiment, the vehicle body moving part D of this embodiment includes two driving track wheels 22, two driven track wheels 23, two track belts 24, two baffle plates 25, two drive motors 27, two second One driven gear 30, two first driving gears 28, two support frames 33, four axles 29, eight third ball bearings 31 and eight bearing blocks 32, each bearing seat 32 is provided with a third ball bearing Bearing 31, the two end faces of each third ball bearing 31 are provided with bearing retaining ring 36, respectively are installed with two wheel axles 29 on the front and rear ends of car shell 21, two wheel axles 29 of front end are with car shell 21 The longitudinal center line N-N is symmetrically arranged on the outer side walls of the car shell 21 both sides, and the two wheel axles 29 at the rear end are arranged on the outer side walls of the car shell 21 both sides symmetrically wit...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination Figure 4 Describe this embodiment, the mobile telescopic mechanism A2 of this embodiment comprises telescopic motor 16, motor base 18, drive gear 19, the 3rd rack 20, two slide rails 17 and two slide blocks 35, two slide rails 17 along The longitudinal parallel of the vehicle housing 21 is fixed on the upper surface of the bottom of the vehicle housing 21, and each slide rail 17 is equipped with a slide block 35 slidingly connected thereto, and the slide block 35 is fixedly installed on the lower end surface of the telescopic arm body 3-1. On the telescopic arm body 3-1, the end opposite to the connecting shaft 11 is fixedly equipped with a motor seat 18, and the telescopic motor 16 is installed on the motor seat 18, and the output shaft of the telescopic motor 16 is provided with a driving gear 19 through a key sleeve, and the driving gear 19 meshes with the third rack 20, the third rack 20 is fixedly mounted on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com