A brake command signal generator for driver controller

A technology of signal generating device and driver controller, applied in railway braking system, operating mechanism of railway vehicle brake, locomotive, etc., can solve the problem of rotary potentiometer overload and overheating, no protection, easy to burn out rotary potentiometer, etc. , to achieve the effect of improving service life and working reliability, and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

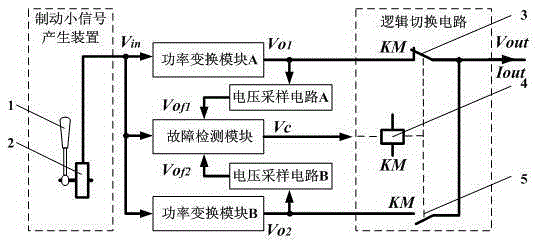

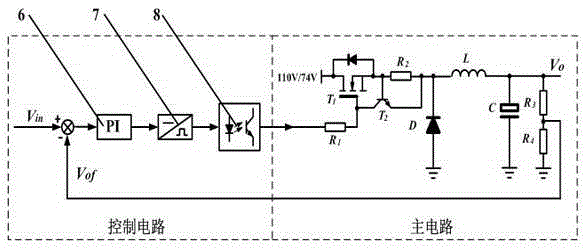

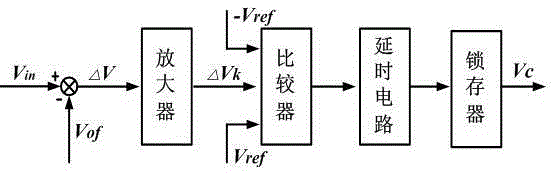

[0015] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 As shown, the present invention is composed of a braking small signal generating device, a power conversion module A, a power conversion module B, a voltage sampling circuit A, a voltage sampling circuit B, a fault detection module and a logic switching circuit. The output end of the braking small signal generating device is respectively connected to the input ends of the power conversion module A, the power conversion module B and the fault detection module, and the voltage sampling circuit A is connected in series between the power conversion module A and the fault detection module, and the power conversion module B and the fault detection module are connected in series. The voltage sampling circuit B is connected in series between the fault detection modules; the output ends of the power conversion module A, the power conversi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap