Conveying mechanism for disk-shaped part

A transmission mechanism and parts technology, which is applied in the field of disk-shaped parts transmission mechanism, can solve the problems of complex structural design and inability to efficiently transfer disk-shaped parts, and achieve the effects of reducing production costs, shortening production cycle, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

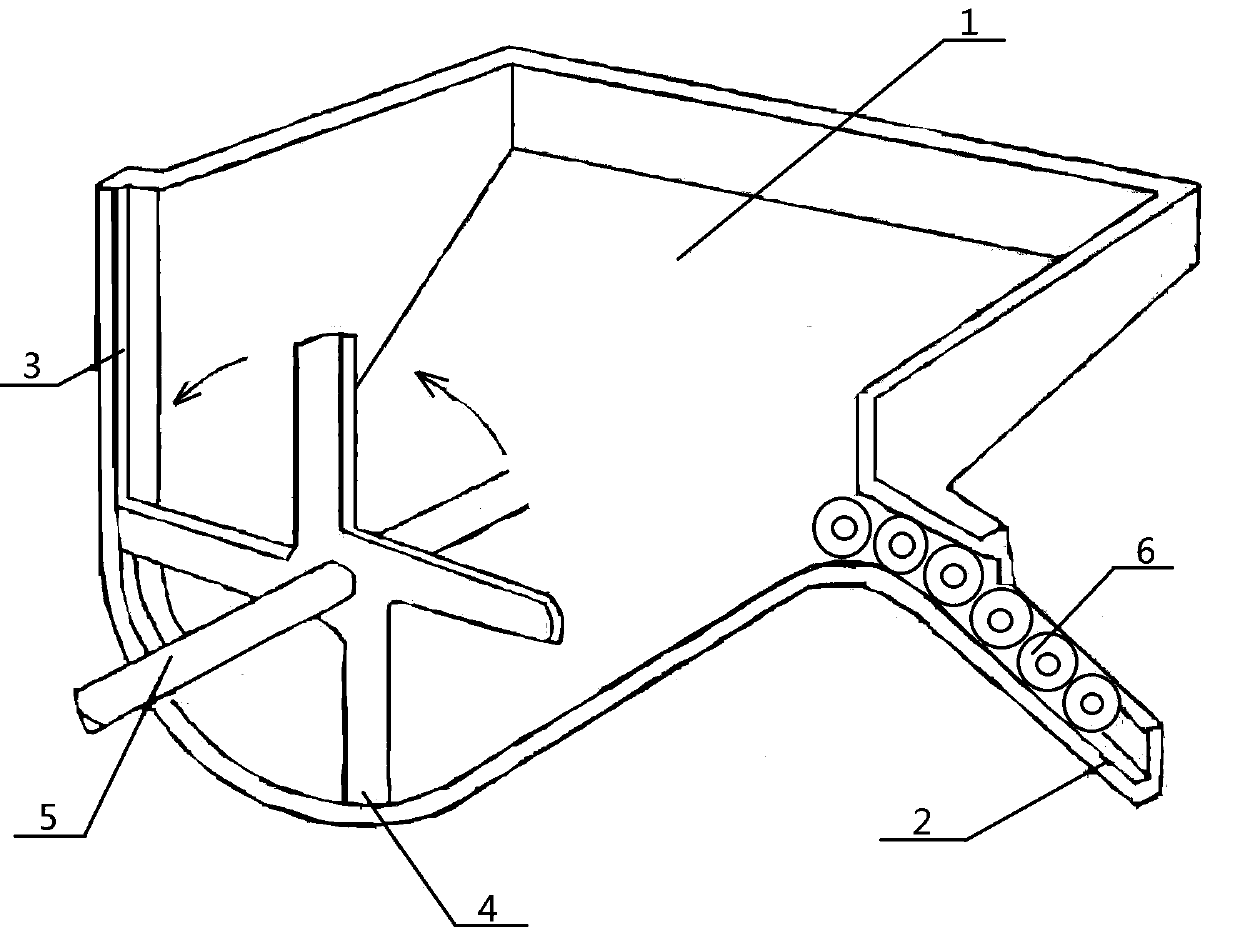

[0007] Such as figure 1 As shown, the present invention provides a disc-shaped parts transmission mechanism, including a hopper 1, the hopper 1 is provided with a discharge port 2, and also includes a paddle wheel 4, the inner wall of the hopper 1 is provided with a groove 3, and the groove 3 is connected to the discharge port 2 In the same plane, the groove 3 communicates with the discharge port 2; the paddle wheel 4 cooperates with the groove 3, and the center of the paddle wheel 4 is provided with a rotating shaft 5, and the paddle wheel 4 is slidably connected with the hopper 1 through the rotating shaft 5.

[0008] During use, the hopper 1 is filled with the disc-shaped part 6, and then the power end of the rotating shaft 5 is started to rotate the paddle wheel 4 in the groove 3, so that the disc-shaped part 6 moves forward along the groove 3, and continues Go forward and enter the discharge port 2 to realize the efficient transmission of the disc-shaped parts 6.

[0009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com