A pressure roller device for improving strip stability

A pressure roller device and stability technology, which is applied in the field of pressure roller device to improve the stability of the strip, and can solve problems affecting the quality of the plate surface, insufficient guide rollers, vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The invention relates to the technical field of finishing equipment for metal strips, in particular to a pressing roller device for improving the stability of strips.

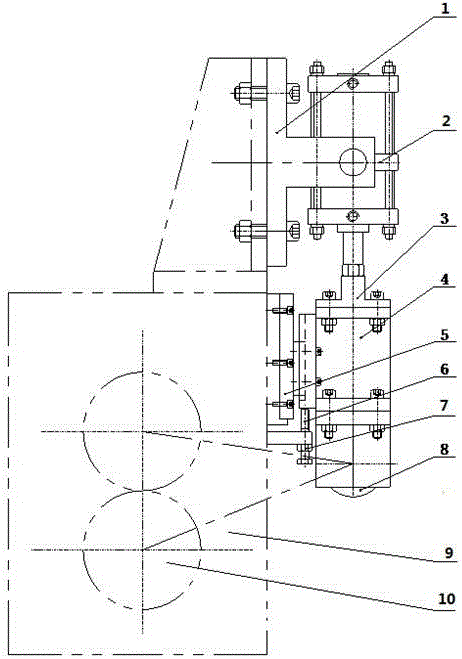

[0012] see figure 1 , the concrete structure of a kind of improving strip stability pressure roller device that the present invention relates to is:

[0013] Including cylinder base 1, cylinder 2, cylinder joint 3, beam 4, linear guide rail 5 and pressure roller assembly 8; among them,

[0014] Cylinder base 1 and linear guide rail 5 are respectively installed on the frame 9,

[0015] The cylinder 2 is installed on the cylinder base 1, and the cylinder 2 is connected with the beam 4 through the cylinder joint 3,

[0016] The pressure roller assembly 8 is installed under the beam 4, and the guide groove on the beam 4 can move linearly along the linear guide rail 5,

[0017] The crossbeam 4 is locked in position by a position locking device to limit the maximum displacement of its downward movement. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com