Internal pressure detecting device for aerosol tank

A technology of aerosol cans and inspection devices, applied in measuring devices, measuring fluid pressure, instruments, etc., can solve problems such as affecting test data, easily generating fatigue, polluting pressure gauges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

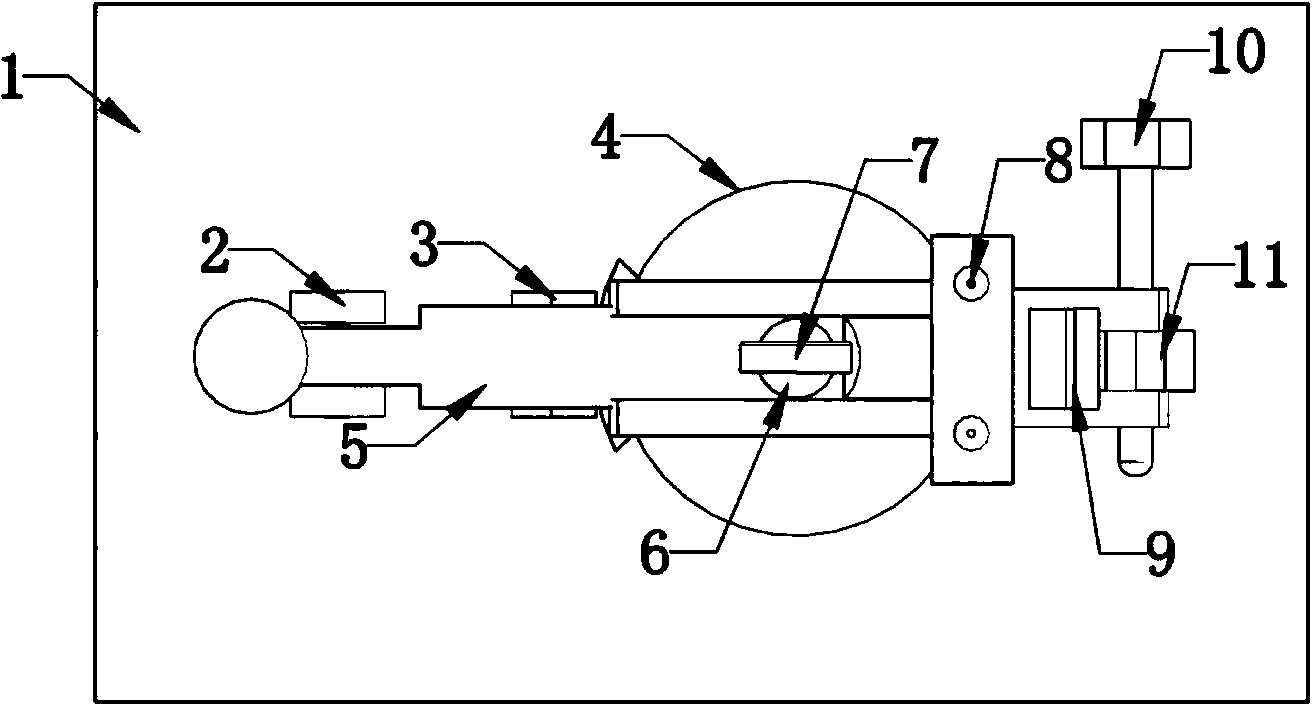

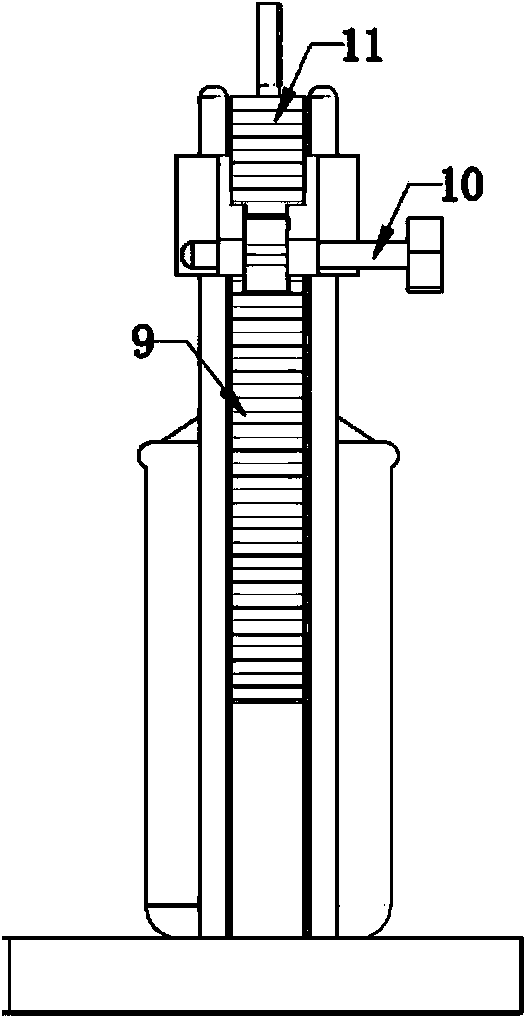

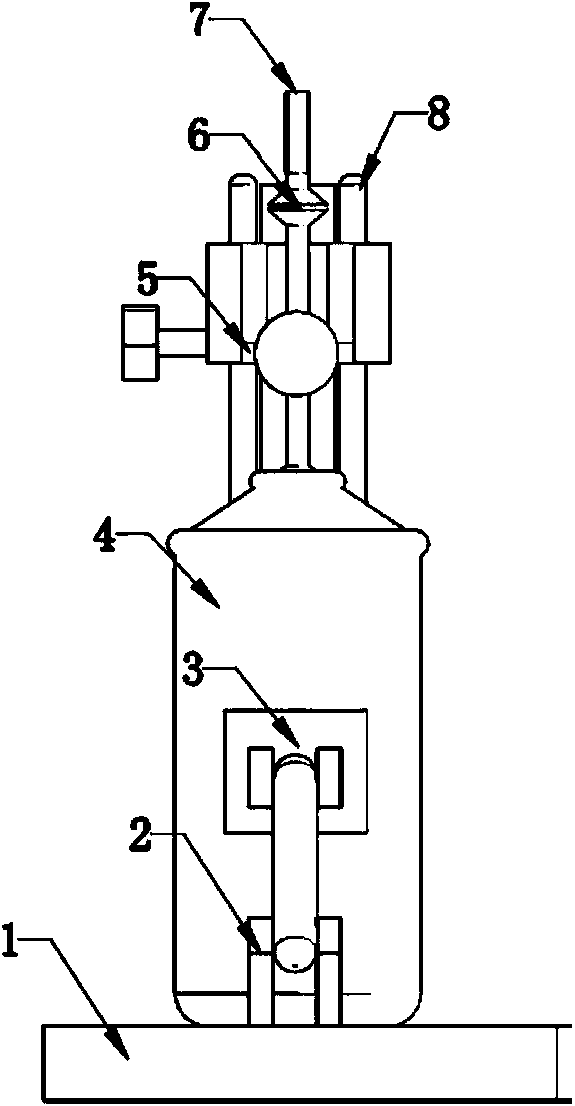

[0029] Such as Figure 1~5 As shown, an aerosol tank internal pressure inspection device, the device includes a base 1, and a pressure detector arranged on the base 1, a fixed bracket 2, a fixed rubber sheet 3, an aerosol tank body 4, a rack and pinion Mechanism, positioning structural column 8, telescopic positioning member 5, positioning adjustment handle 10;

[0030] The pressure detector includes an isolation membrane box 6 and a pressure gauge 7 arranged thereon, and the isolation membrane box 6 is connected to the aerosol spray pipe of the aerosol tank 4 . The isolation diaphragm box can effectively prevent the pollution of the pressure gauge caused by the aerosol spray without hindering the pressure detection.

[0031] The fixed bracket 2 is connected to the base 1, the fixed bracket 2 is equipped with a spring, so that the fixed bracket 2 always maintains the force applied in the direction of the positioning structure column 8, and a fixed rubber sheet 3 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com