Accelerated corrosion test device for nonferrous metal soil

An accelerated corrosion test, non-ferrous metal technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of long measurement time, time-consuming and labor-consuming measurement, and achieve short measurement time and simple structure , the effect of convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

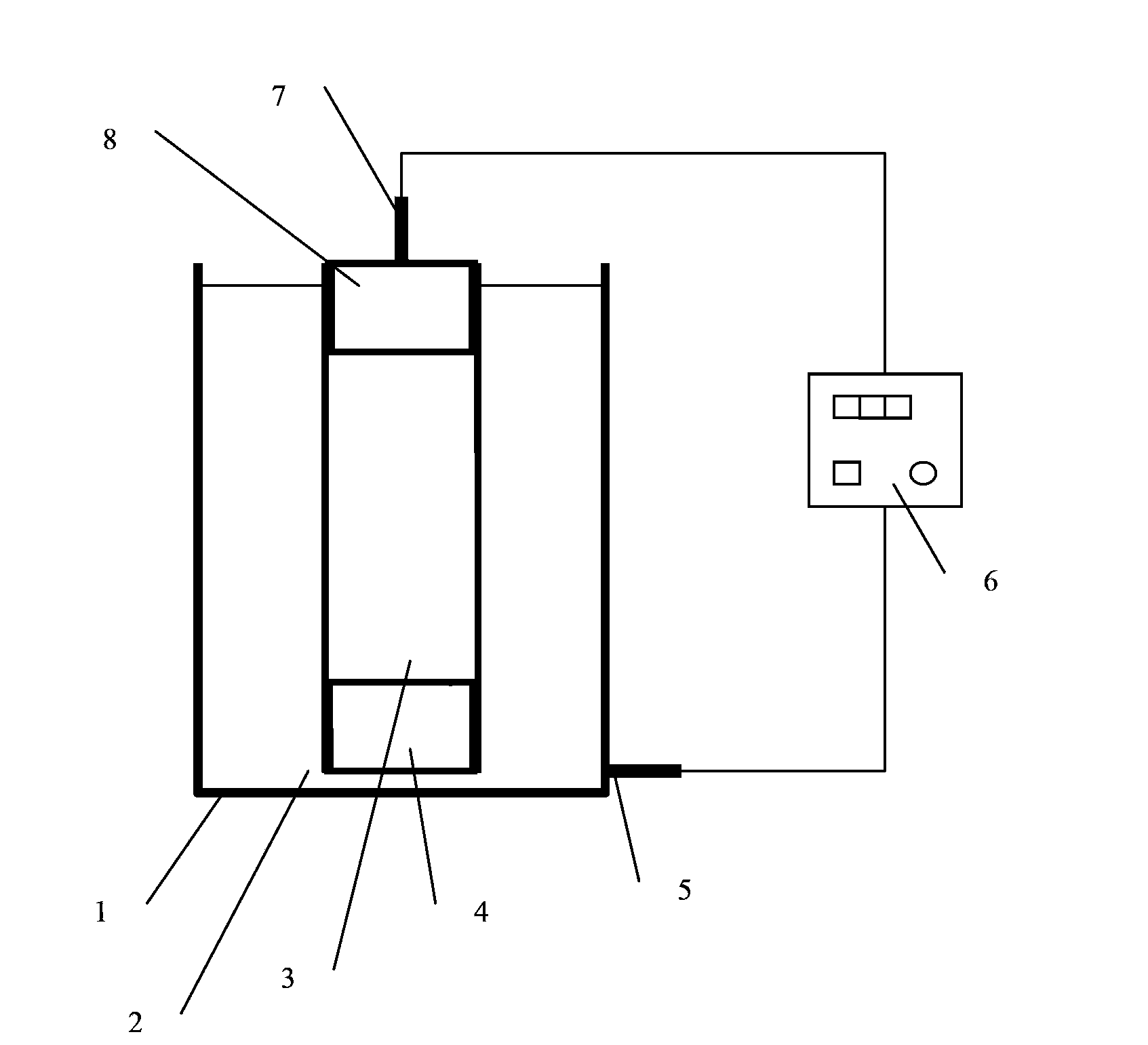

[0017] Such as figure 1 As shown, the non-ferrous metal soil accelerated corrosion test device of the present invention includes a conductive container 1, a corrosive medium 2, a metal tube 3, a lower rubber plug 4, a direct current negative terminal 5, a direct current power supply 6, a direct current positive terminal 7, and an upper rubber plug. Plug 8 etc., the specific structure is as follows:

[0018] The conductive container 1 is equipped with a corrosive medium 2, and the upper and lower ends of the metal tube 3 are respectively plugged with an upper rubber stopper 8 and a lower rubber stopper 4. The metal tube 3 is placed in the corrosive medium 2 of the conductive container 1, and the upper end of the metal tube 3 is connected to a direct current. The positive pole terminal 7 is connected to the positive pole of the DC power supply 6 through a wire. The outer surface of the conductive container 1 is provided with a DC negative terminal 5, and the DC negative termina...

Embodiment 2

[0021] In this embodiment, the number of conductive containers 1 is more than two, and the DC positive terminal and the DC negative terminal of the two or more conductive containers 1 are connected in parallel and connected to the same DC power supply.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com