A superconducting synchronous motor

A synchronous motor and superconducting technology, applied in the usage of superconductor elements, electrical components, electromechanical devices, etc., can solve the problems of reliability and service life, the existence of rotating contact links, and the reduction of motor efficiency, etc., to achieve extended re-injection The time of refrigerant, the effect of reducing motor load and improving motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

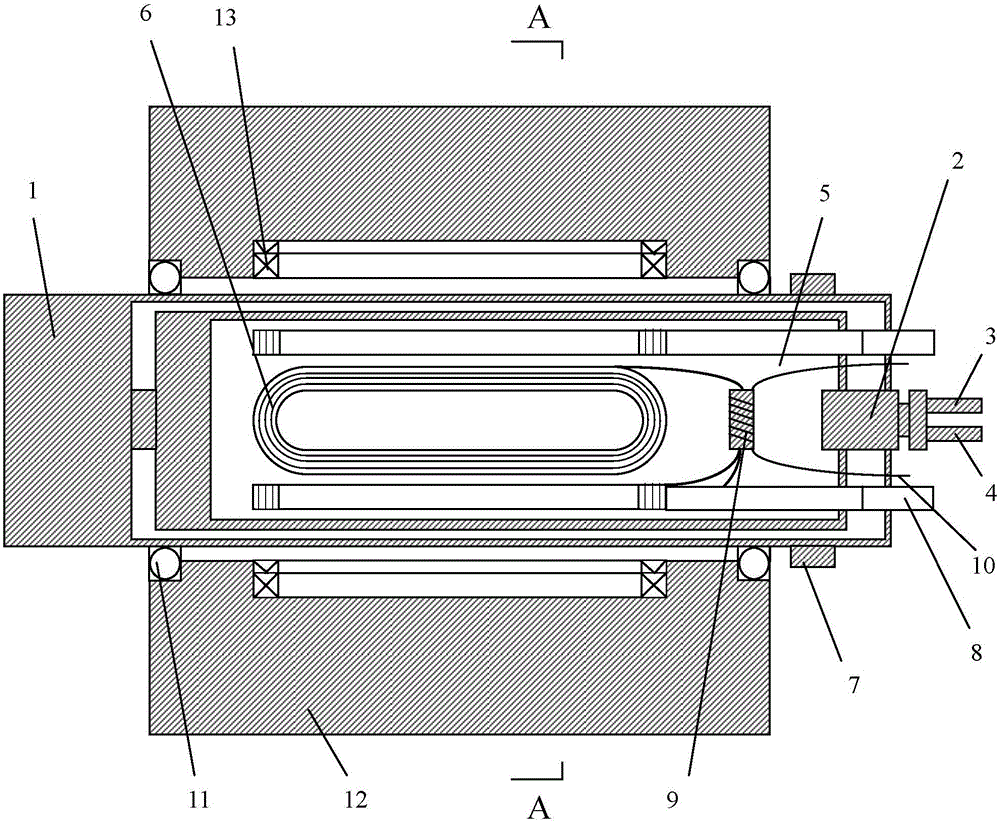

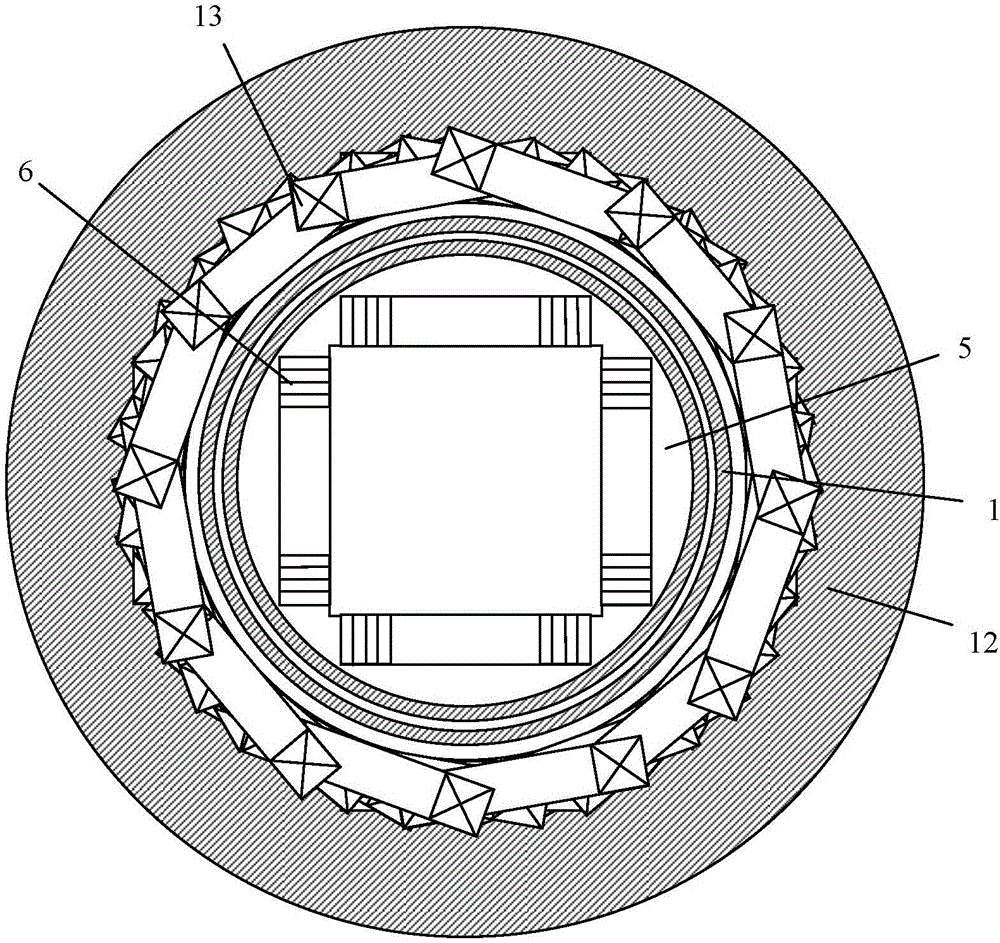

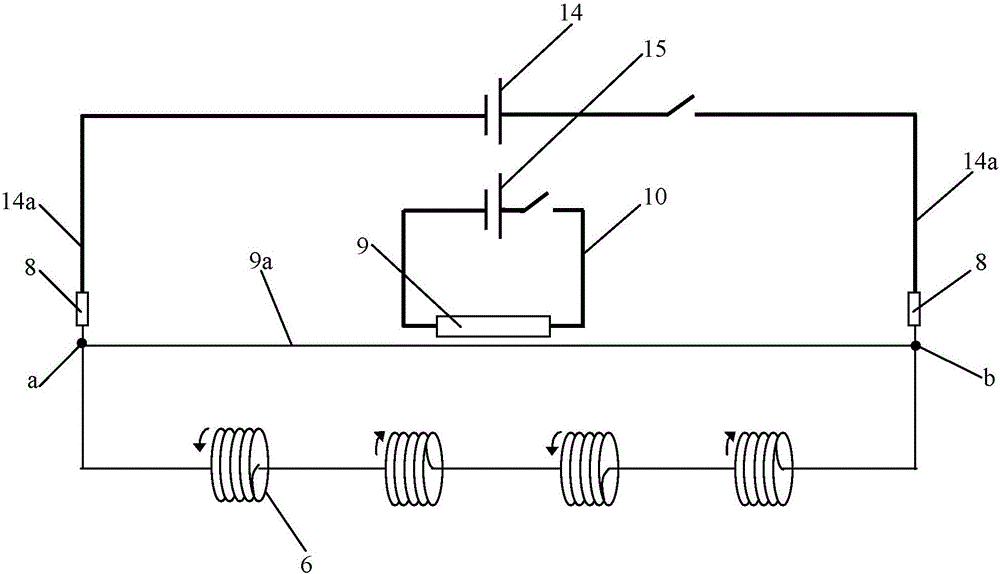

[0029] Figure 1-3 As shown, one embodiment of the present invention is: a superconducting synchronous motor, including a stator 12, a coil 13 on the stator 12, and a superconducting coil 6 excited in the rotor. The superconducting coil 6 is fixed in the cylindrical sealed rotor cavity 5, the rotor cavity 5 is covered with a sealed outer cover 1, the outer cover 1 is provided with a vacuum nozzle 7, and the outer cover 1 is fixed on the stator shell 12 through the bearing 11; One end of the rotor cavity 5 and the outer cover 1 are connected with the rotary joint 2, and the other end of the rotary joint is connected with the refrigerant input pipe 3 and the refrigerant output pipe 4 at the same time; the other end of the rotor inner cavity 5 is connected with the other end of the outer cover 1 One end is fixedly connected; the two leading ends a and b of the superconducting coil 6 are connected to the inner end of the copper sheet 8, and the copper sheet 8 passes through the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com