Camera module

A camera module, image sensor technology, applied in cameras, camera bodies, TVs, etc., can solve the problems of image quality impact, small imaging, small height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

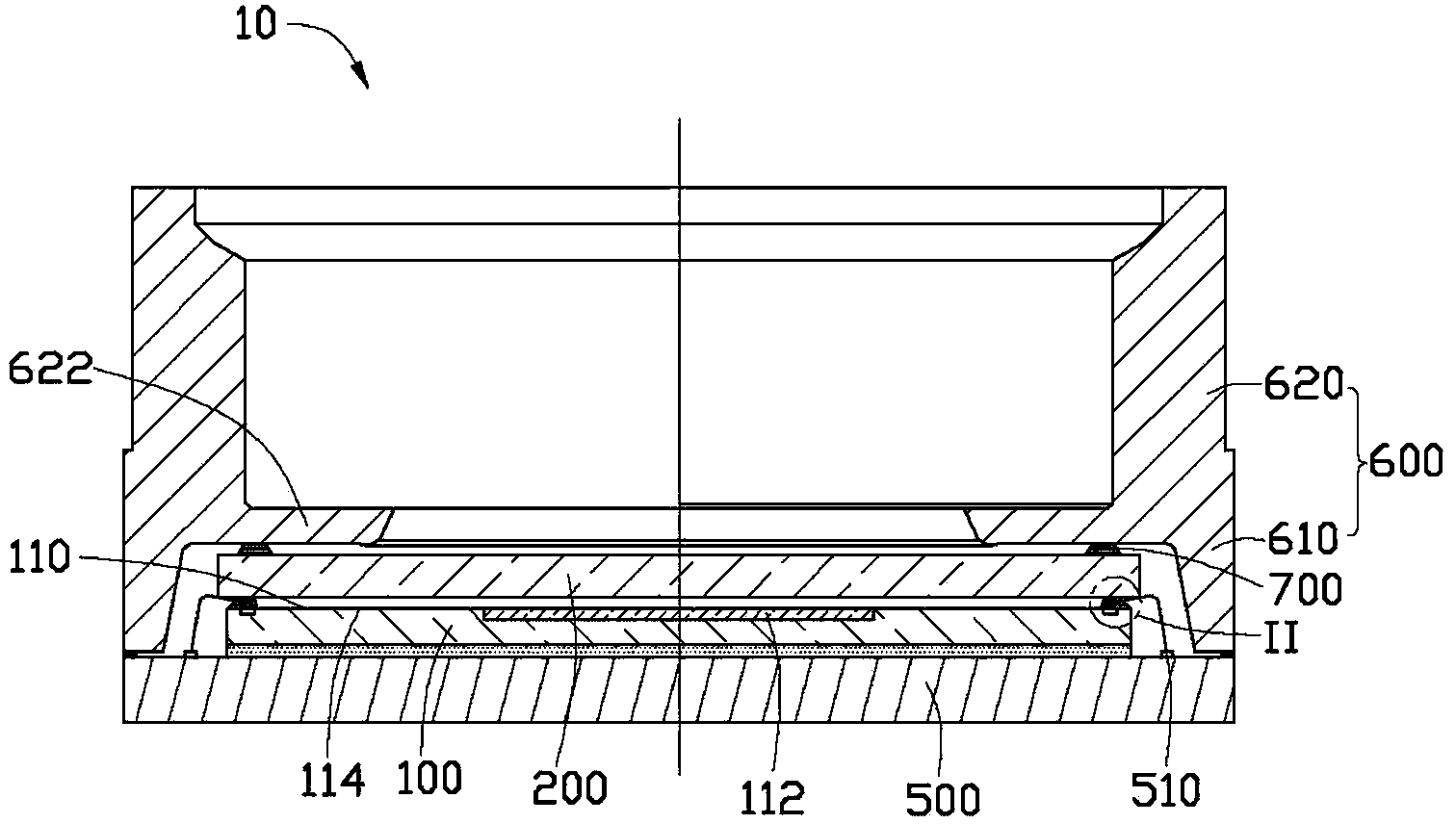

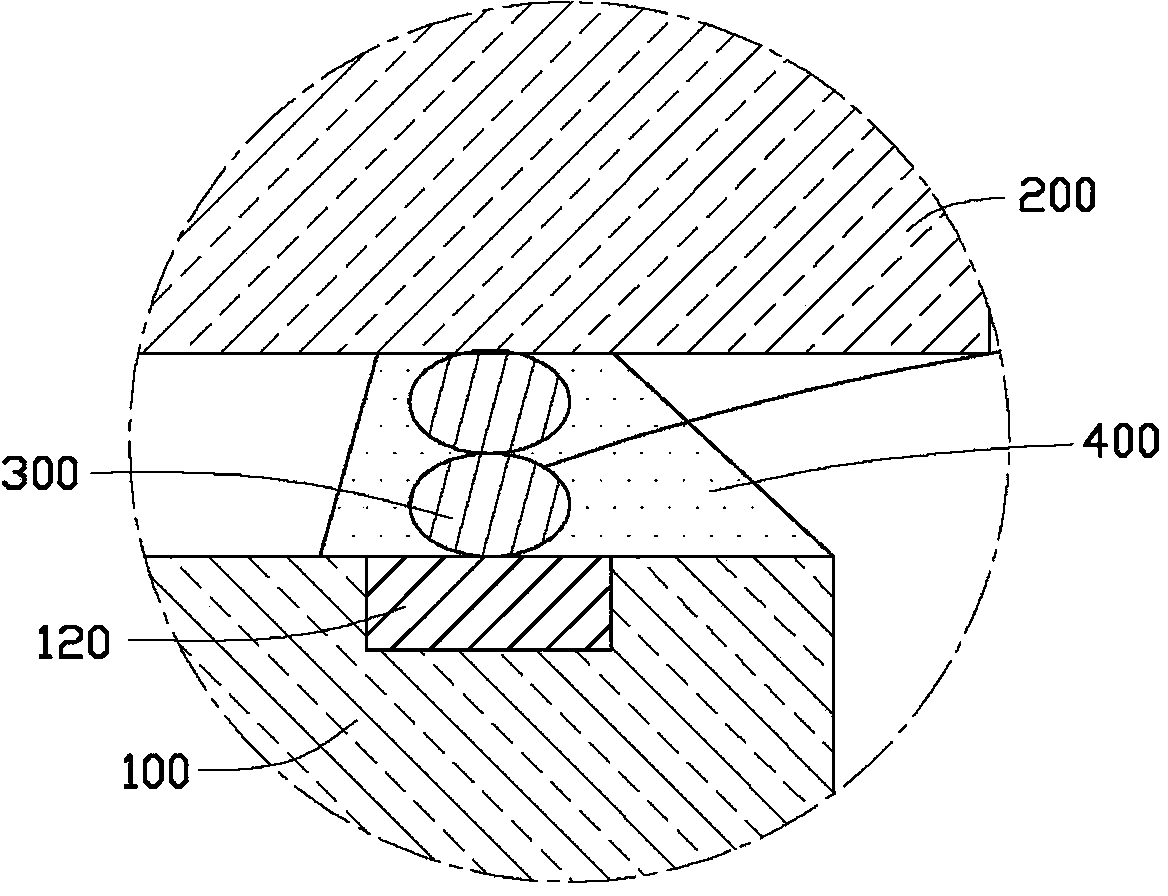

[0011] see Figure 1-2 , a camera module 10 according to a preferred embodiment of the present invention, which includes an image sensor 100 and a filter 200 . The image sensor 100 includes a light-sensing surface 110 for receiving incident light for imaging. The light-sensing surface 110 includes a sensing area 112 and a non-sensing area 114 surrounding the sensing area. The non-sensing area 114 is formed with a plurality of pads 120 . The filter 200 is disposed on the image sensor 100 . At least one metal ball 300 is stacked on at least three of the solder pads 120 . The number of the metal balls 300 on each of the bonding pads 120 is the same. The optical filter 200 is disposed on the metal ball 300 .

[0012] The camera module 10 utilizes the metal ball 300 to separate the image sensor 100 and the filter 200 at a relatively long distance, thereby reducing the influence of dust that may adhere to the filter 200 on the imaging quality and improving the imaging quality. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com