A cold drawing treatment device for stainless steel pipe

A stainless steel pipe and processing device technology, which is applied in the field of lubricant devices, can solve the problems of steel pipe surface pressing and product quality degradation, and achieve the effects of improving work efficiency, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings.

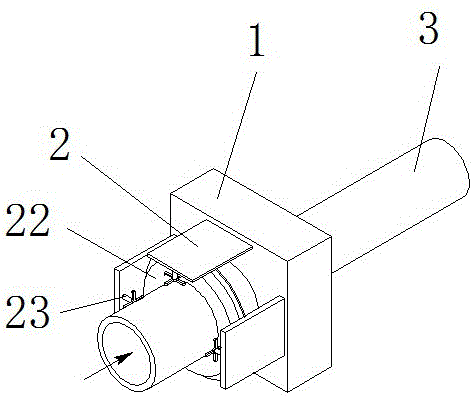

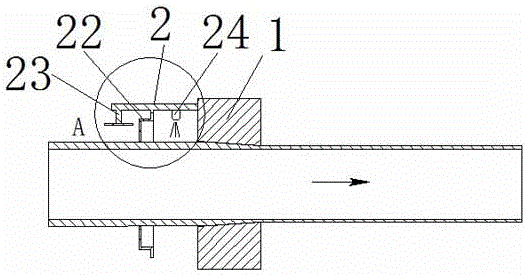

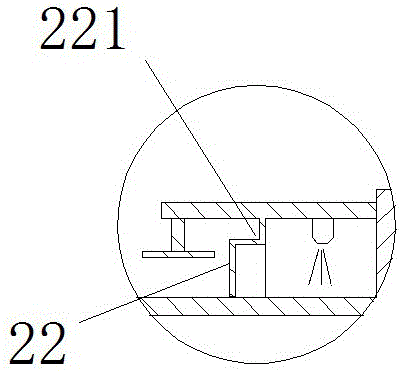

[0018] according to Figure 1-3 As shown, a cold drawing processing device for stainless steel pipes includes a cold drawing die 1, and also includes three substrates 2 arranged in front of the cold drawing die 1. The substrates 2 are distributed in a triangular shape. The shower head 24 and the air blowing device 23; each substrate 2 is connected to a scraper 22 in common. The position of the scraper 22 is located in the middle of the shower head 24 and the blowing device 23 . In the direction of movement of the stainless steel pipe, it first passes through the blowing device 23 , then passes through the scraper 22 , and finally passes through the shower head 24 . Blowing device 23 one is to remove the large-scale particle of steel pipe surface like this, and the 2nd, blows off the redundant lubricant that is scraped off by scraper 22. And shower head 24 just can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com