Pressure accuracy control method for isotemperature static pressing

A pressure control and precise control technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of simple algorithm, difficult to accurately establish pressure control model, inability to apply to high pressure and high temperature environment, etc., and achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Attached below Figure 1-Figure 11 And specific embodiment, the present invention is further elaborated and illustrated.

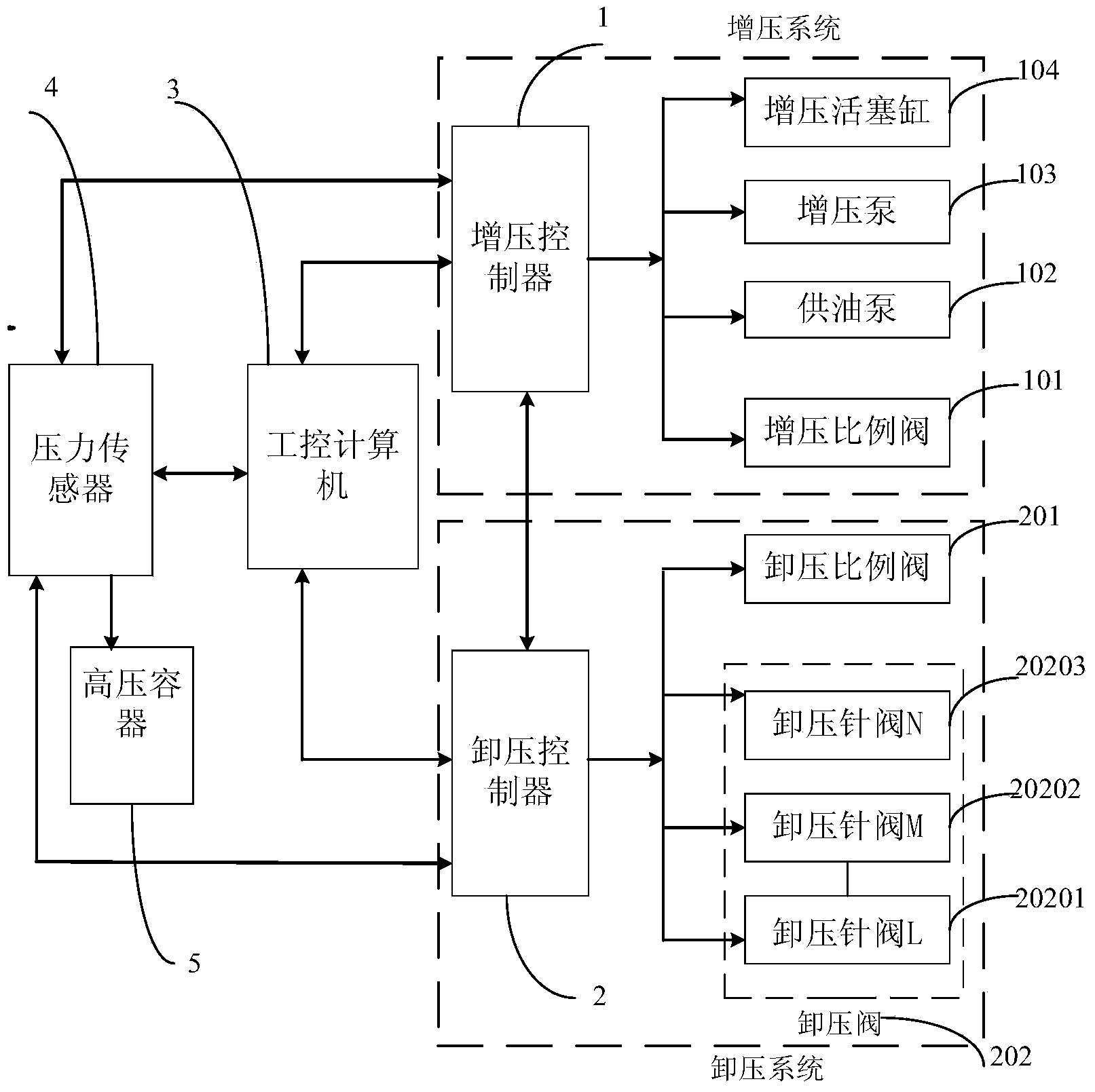

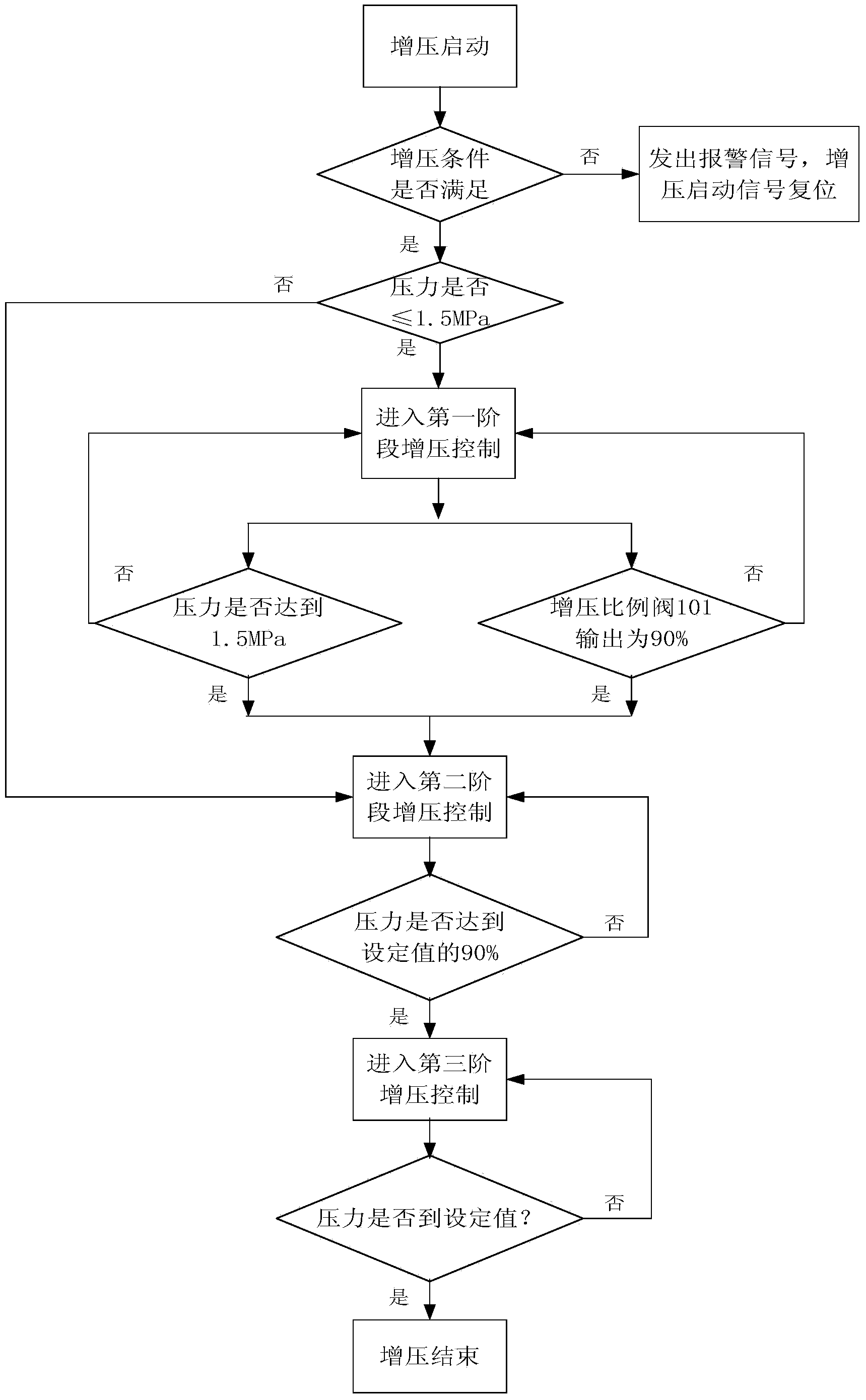

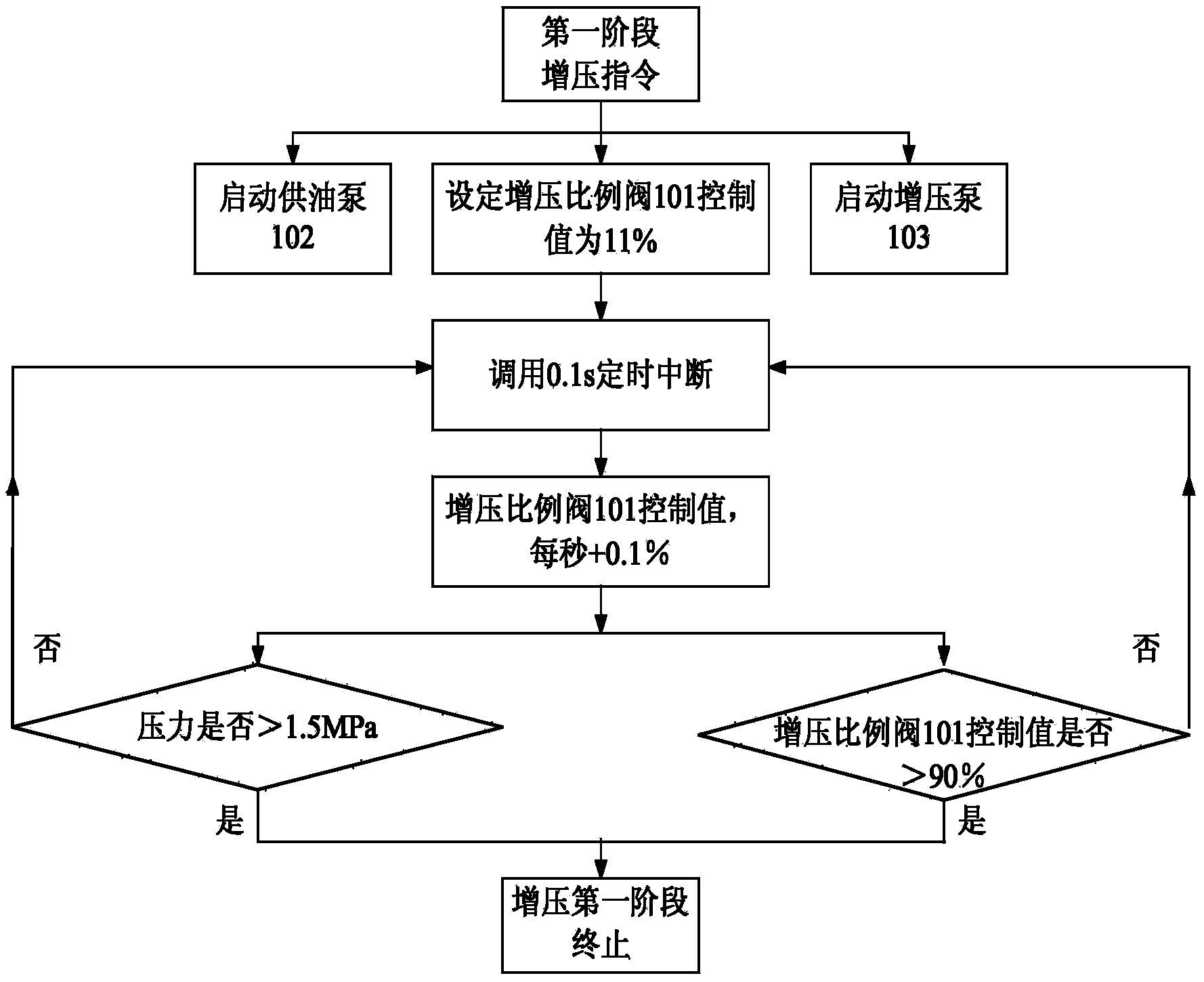

[0035] combined with figure 1 , attached figure 2 And embodiment, a warm isostatic pressure precise control method, the pressure control system mainly includes industrial control computer 3, boost control system, pressure relief control system, high pressure container 5 and pressure sensor 4, said boost control system includes Boost controller 1, boost proportional valve 101, oil supply pump 102, boost pump 103, and boost piston cylinder 104, the pressure relief control system includes pressure relief controller 2, pressure relief proportional valve 201, pressure relief valve 202. The pressure control process of the pressure control system is a segmented control step including booster segment control and pressure relief segmental control, and the booster segmental control includes at least the first-stage booster control, the second-stage booster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com