Duplex table transmission gear

A transmission device and double shaker technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of low efficiency, waste of labor costs, waste of time, etc., to save labor costs, improve work efficiency, Compile flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

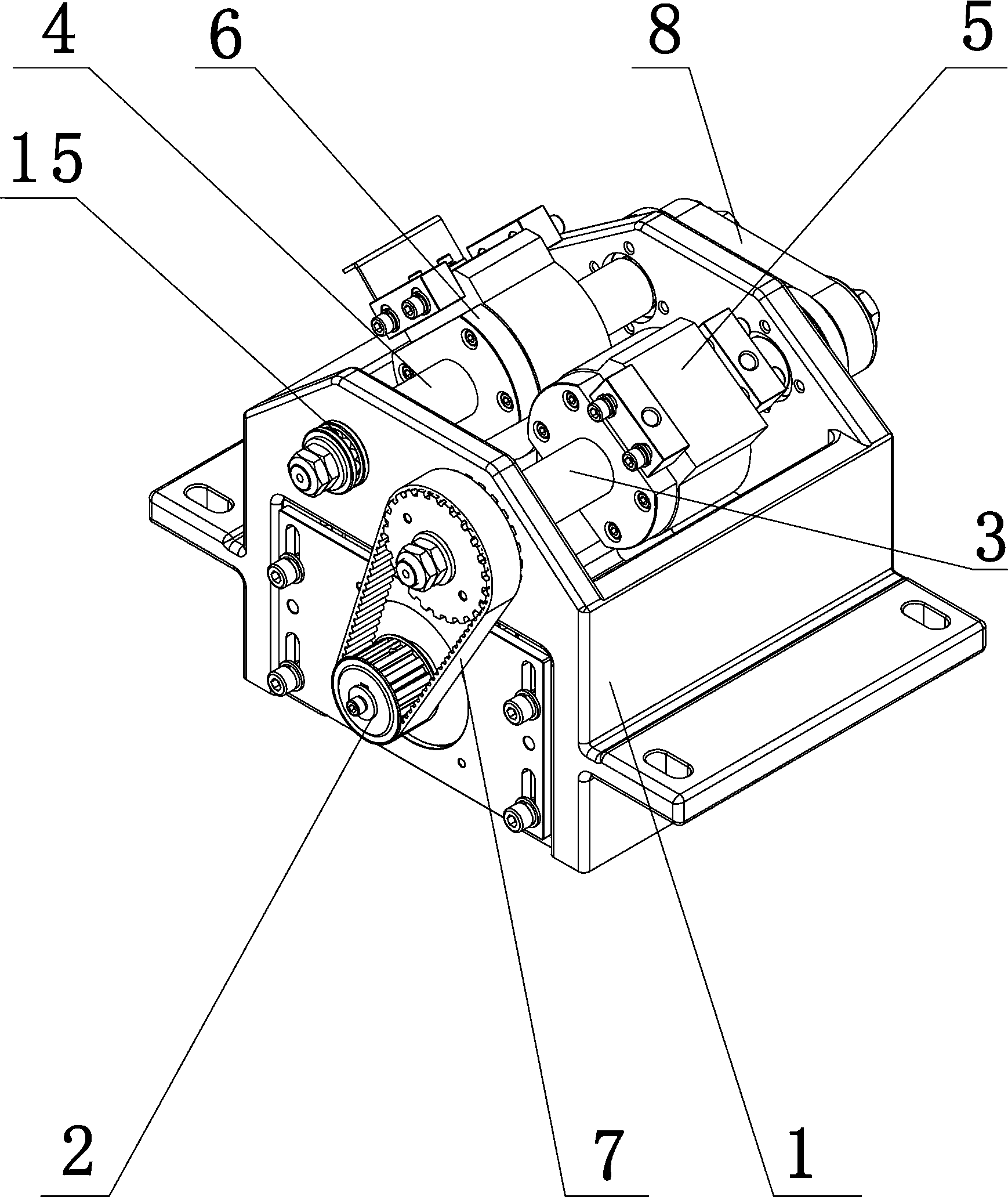

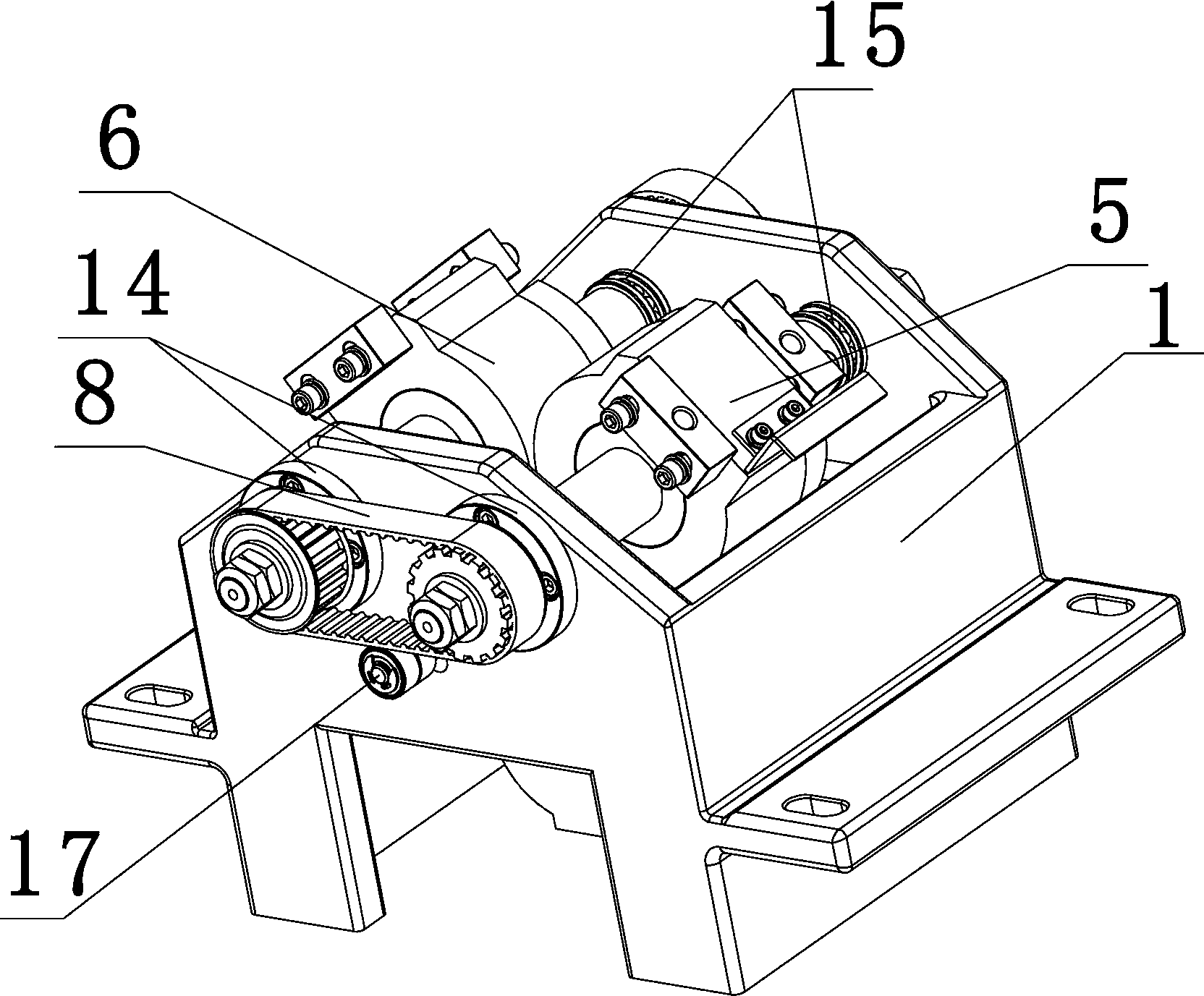

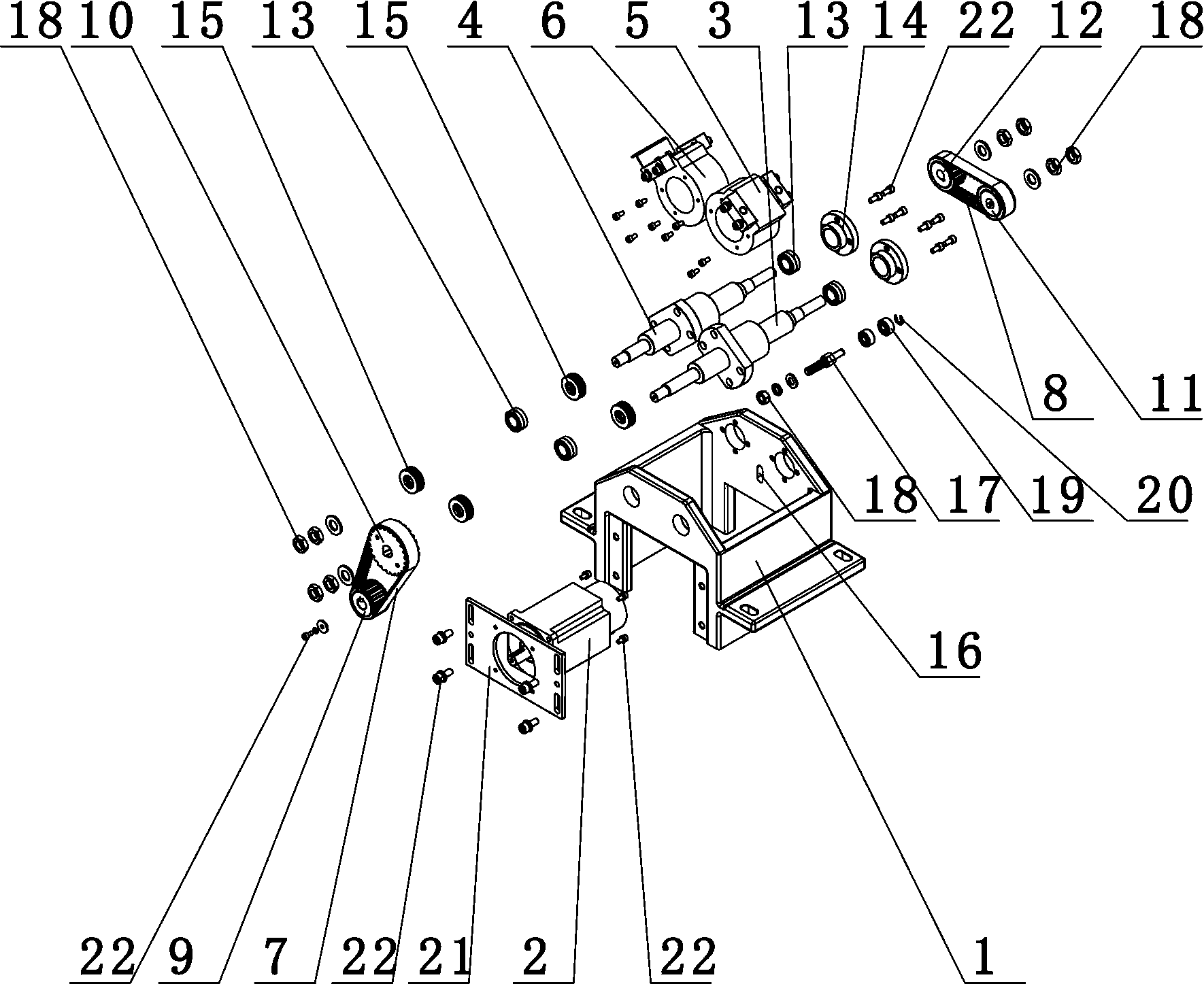

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0022] As an embodiment of the double-shaking table transmission device of the present invention, such as figure 1 , figure 2 and image 3 As shown, it includes a shaker base 1 and a servo motor 2, the servo motor 2 is fixed on the shaker base 1, and the shaker base 1 is provided with two parallel first ball screws 3 and a second Two ball screws 4, the first ball screw 3 is movably connected with a first hanger 5, the second ball screw 4 is movably connected with a second hanger 6, one end of the first ball screw 3 It is connected with the servo motor 2 through the first synchronous belt 7 , and the other end is connected with the second ball screw 4 through the second synchronous belt 8 .

[0023] In this embodiment, the output end of the servo motor 2 is provided with a motor synchronous wheel 9, and the end of the first ball screw 3 in the same di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com