Steel wire creep property testing machine

A testing machine and creep test technology, applied in the direction of testing the ductility of materials, etc., can solve the problems of unstable experimental force, difficult control of material temperature, constant temperature of steel wire, stable test environment, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

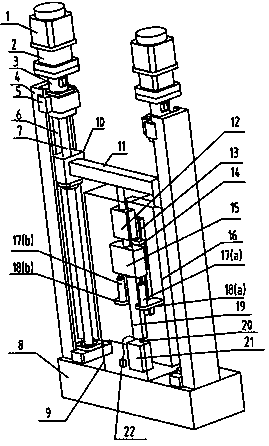

[0014] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

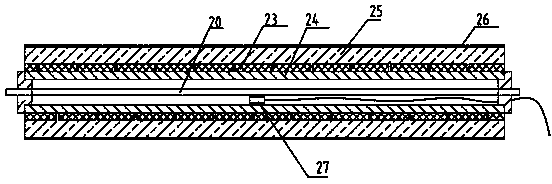

[0015] Steel wire creep performance test process: First, according to the steel wire to be tested, the steel wire 20 is first installed on the lower wire fixer; the copper tube is selected as the heating tube 24, and the electric heating belt 23 is wound on the copper tube to ensure that the electric heating belt is in the The upper part and the lower part of the heating tube are tight, and the middle part is sparse; then the outer layer of the heating belt is wrapped around the thermal insulation cotton 25; the thermal insulation cotton is wrapped tightly with the winding belt 26; The middle part; the electric heating band, the temperature sensor are connected with the temperature controller 22, and the two ports of the heating pipe are sealed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com