Temperature control device for intelligent production line of potassium chlorate

A technology of temperature control device and production line, which is applied in the direction of using electric means for temperature control, auxiliary controller with auxiliary heating device, fire rescue, etc. , to achieve the effect of improving air quality, increasing practicability, and intelligently adjusting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

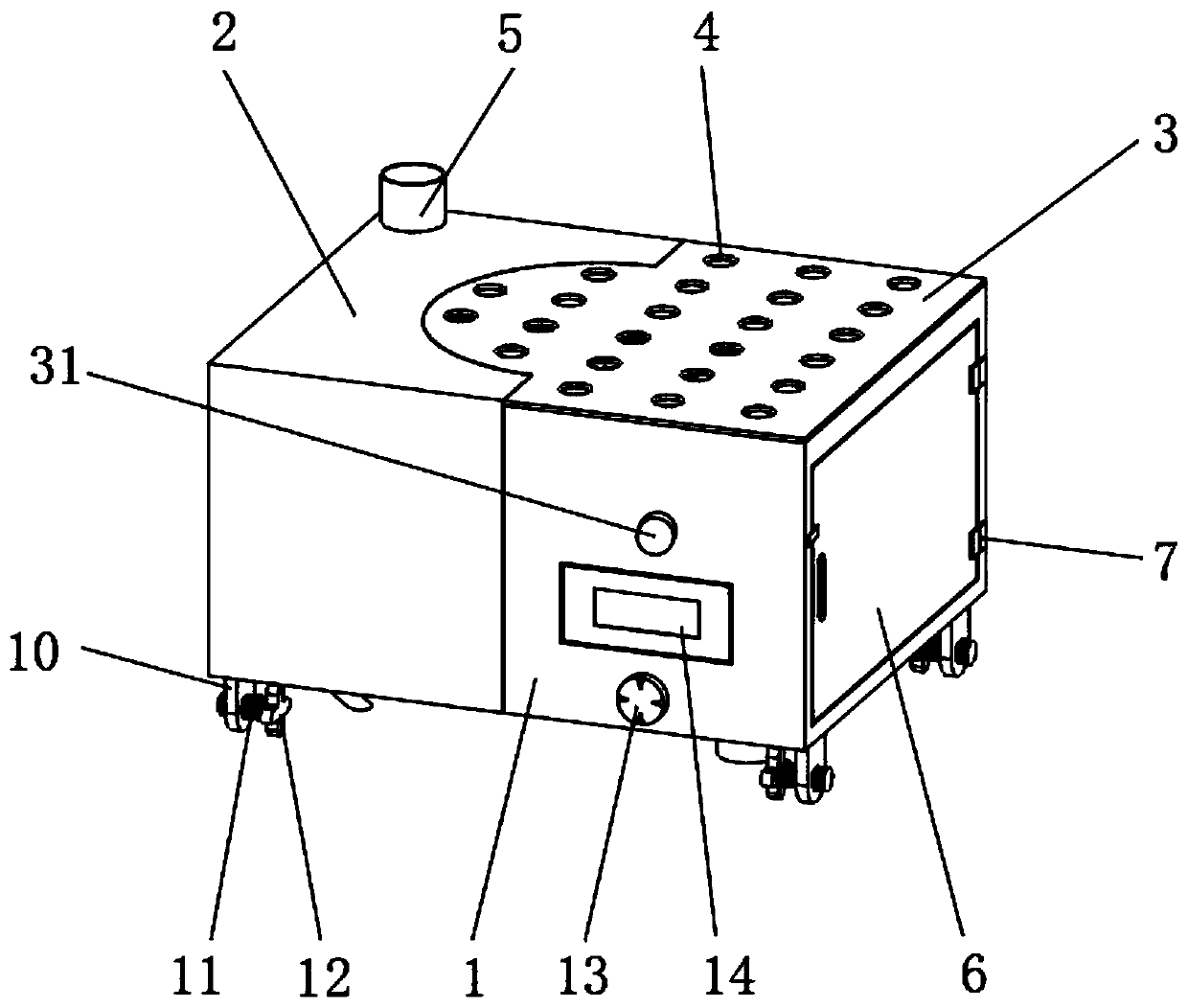

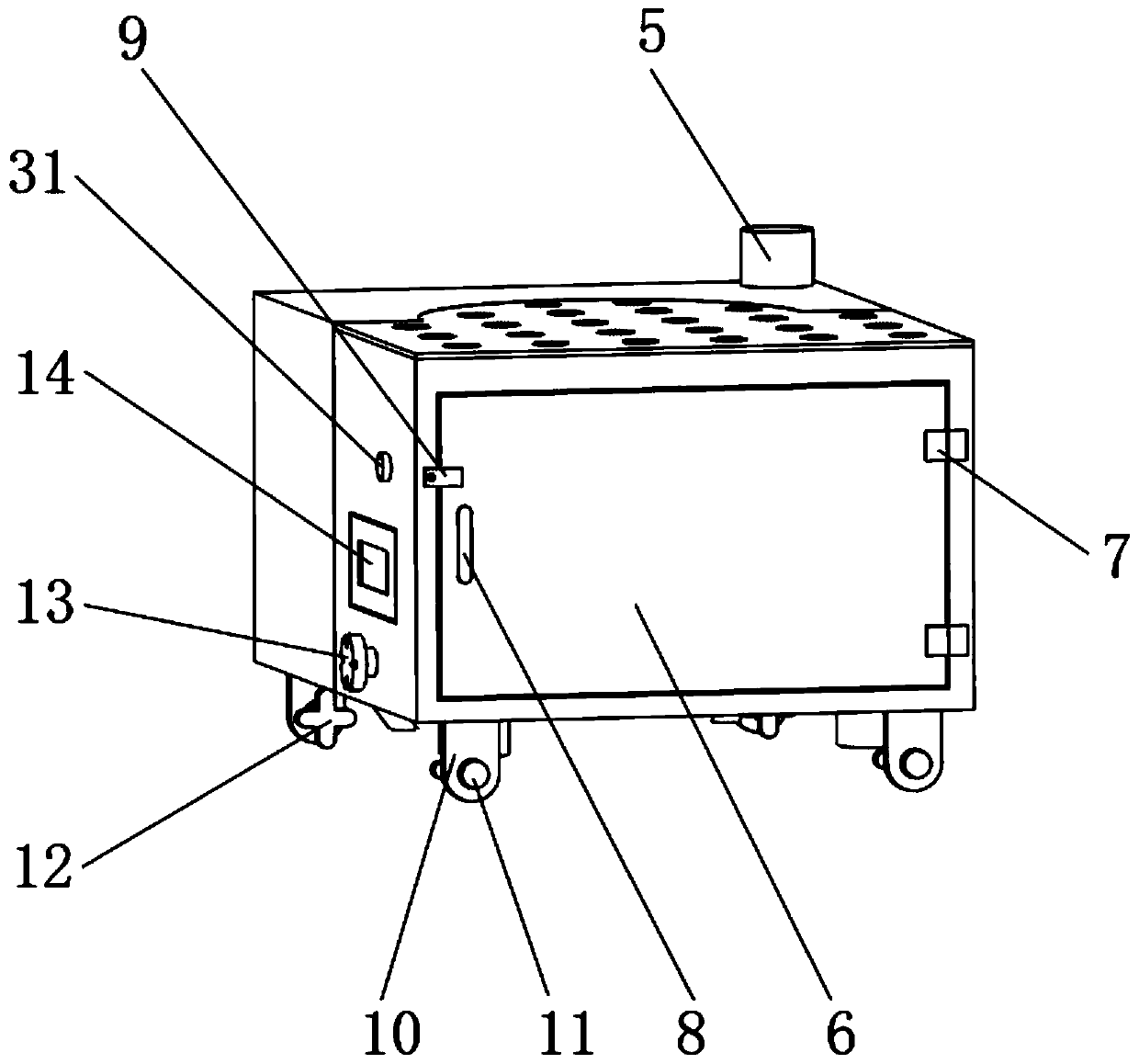

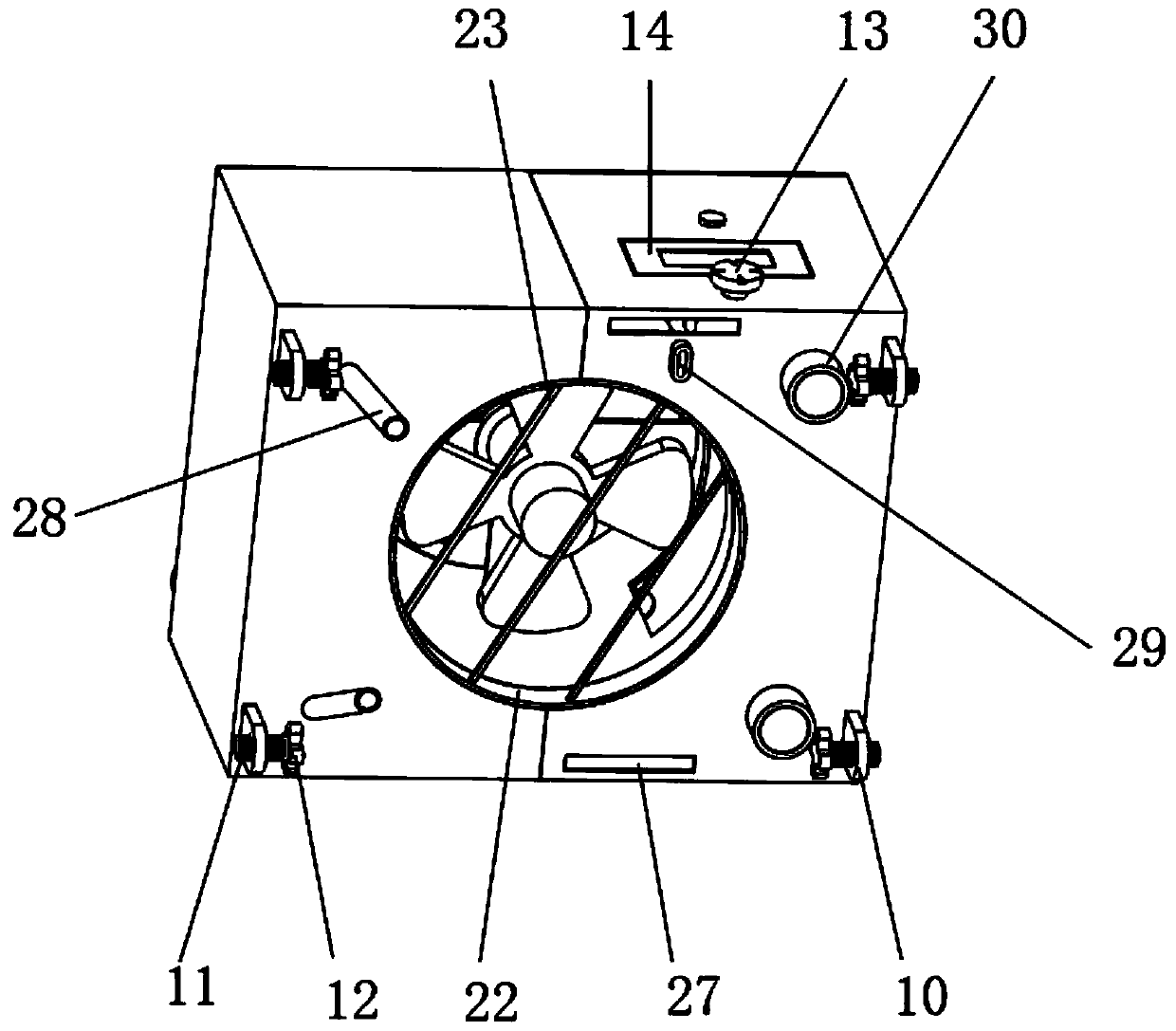

[0033] A kind of temperature control device for potassium chlorate intelligent production line, such as figure 1 , image 3 , Image 6 As shown, it includes a main body 1, the outer wall of the main body 1 is welded with a water tank 2, the top of the water tank 2 is welded with a water inlet 5, the bottom of the water tank 2 is welded with two nozzles 28, and the bottom of the main body 1 is connected by bolts A power supply assembly 24 is fixed, and the inner wall of the bottom of the main body 1 is fixed with a control chamber 25 by bolts, the nozzle 28 is controlled by a solenoid valve in the control chamber 25, and a temperature sensor 29 is fixed on the outer wall of the bottom of the main body 1 by bolts. 1. A buzzer 31 is installed on the outer wall of one side through the buzzer mounting seat. The temperature sensor 29 can detect the external temperature in real time, and feed back the signal to the control room 25 according to the set value, and then control the wor...

Embodiment 2

[0045] A kind of temperature control device for potassium chlorate intelligent production line, such as figure 1 As shown, in order to increase the firmness of the installation in a relatively closed environment; this embodiment makes the following improvements on the basis of Embodiment 1: the outer wall of the bottom of the main body 1 is symmetrically welded with four identical fixing brackets 10, and the fixing brackets 10 The inner wall is threadedly connected with a threaded column 11, and the outer wall of one side of the threaded column 11 is welded with a knob 12. By setting the fixing frame 10, the threaded column 11 and the knob 12, it is possible to rotate the knob 12 in a relatively narrow space such as inside the equipment. The threaded column 11 is stretched out to play the role of supporting auxiliary fixing.

[0046] When this embodiment is in use, when it needs to be installed in a relatively narrow space such as inside the equipment, the threaded column 11 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com