Anti-shedding earthing wire clamp for power transmission line

A technology of transmission lines and grounding clamps, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of ground wires falling out, and achieve the effects of saving time and effort, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

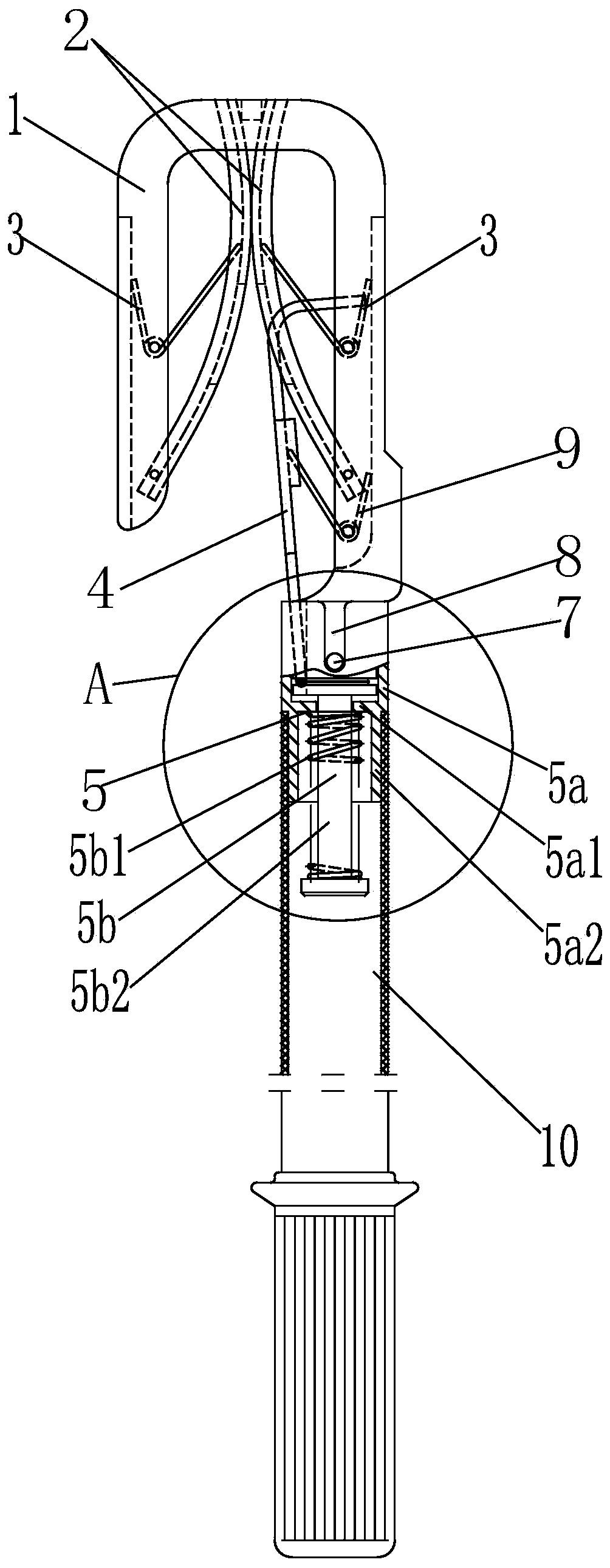

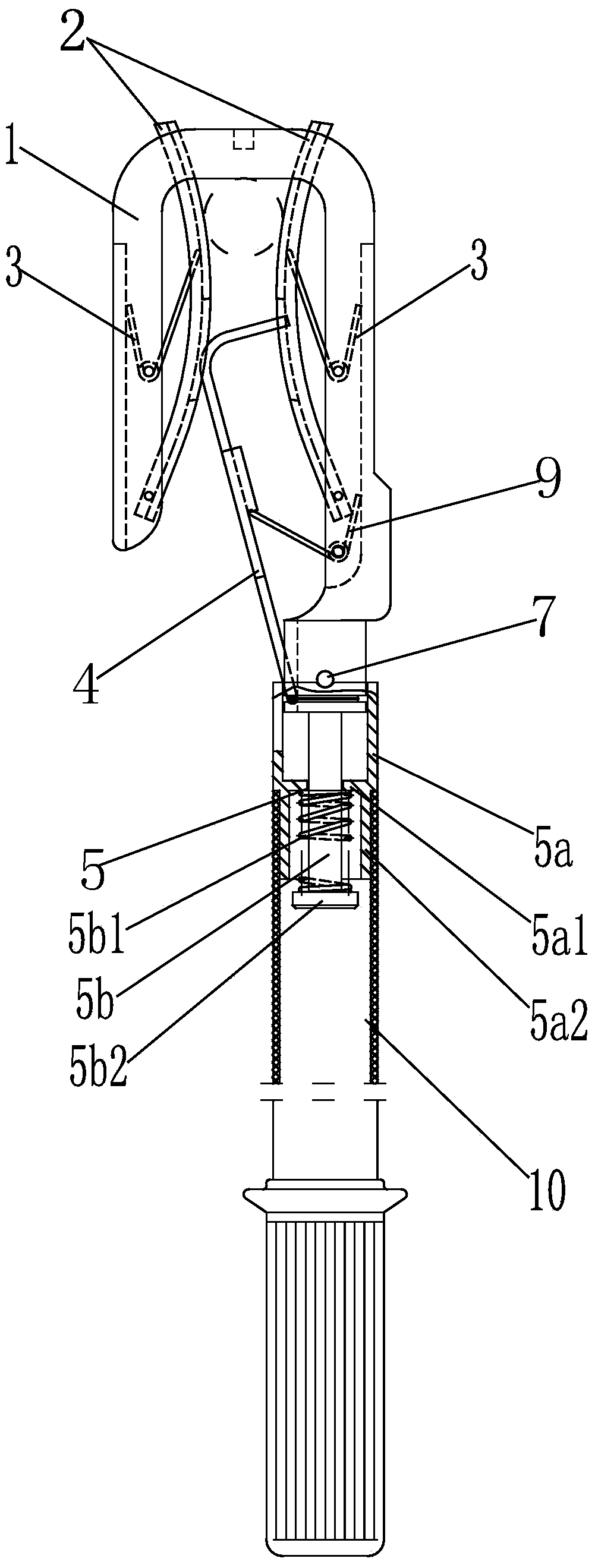

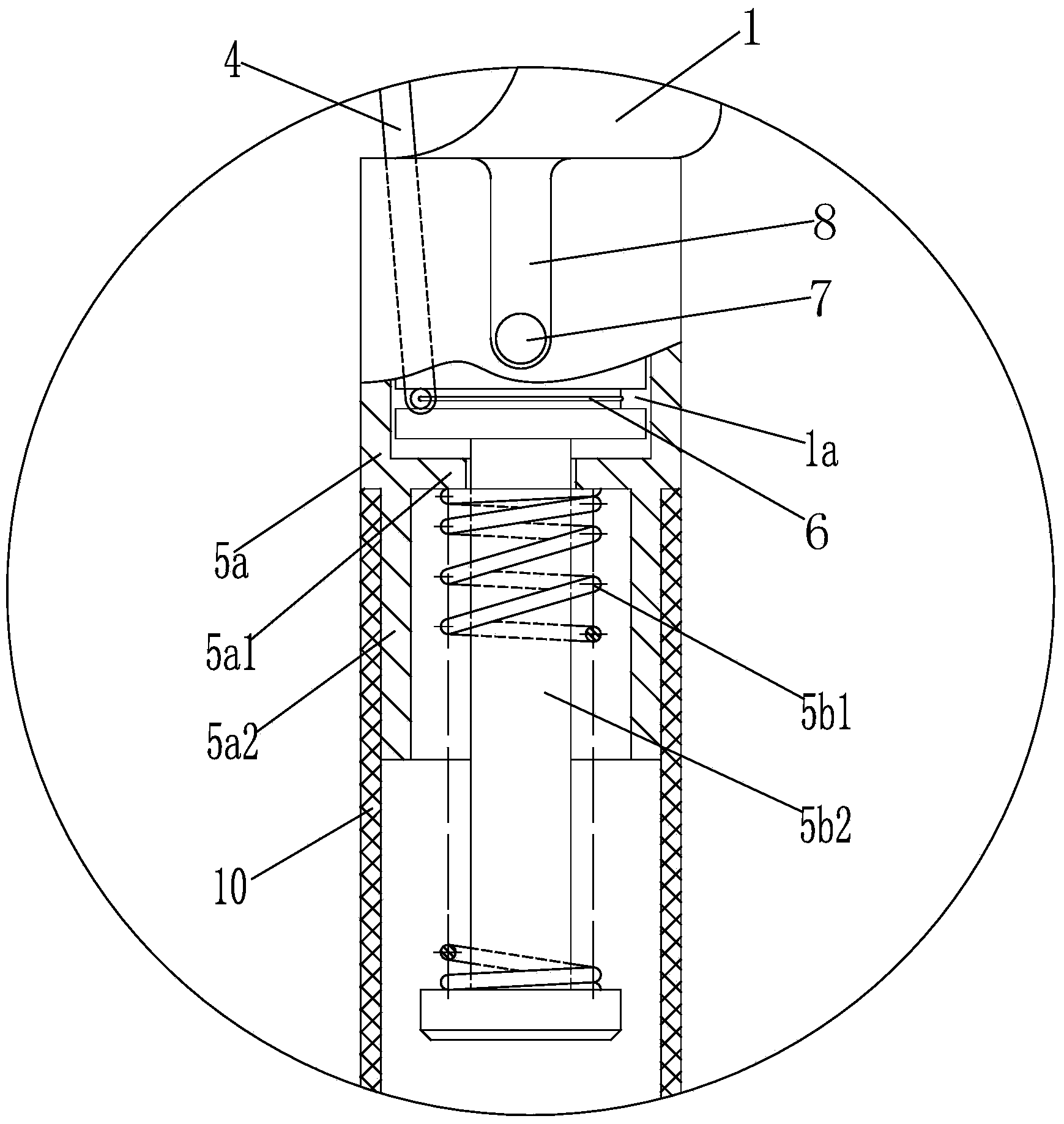

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

[0024] This embodiment provides an anti-dropping grounding clamp for power transmission lines, including a clamp main body 1 and a pair of splints 2, one end of the splint 2 is installed on the clamp main body 1, and the other end of the splint 2 passes through The splint torsion spring 3 is installed on the clamp main body 1, and the clamp main body 1 is provided with a baffle plate 4 for closing the clamping portion of the pair of splints 2, and the clamp main body 1 is provided with a baffle plate for adjusting the An adjustment mechanism 5 for the position of the blocking portion of the baffle 4 . By adopting the technical solution of adding a baffle plate 4 for closing the clamping portion of the pair of clamping plates 2 , the problem in the prior art that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com