Scrap electric wire peeling apparatus

A waste wire and gear shaft technology, applied in the direction of disassembling/armored cable equipment, etc., can solve the problems of poor insulation effect, time-consuming and laborious, metal wire retention, etc., to improve labor efficiency, simple device structure, and manufacturing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

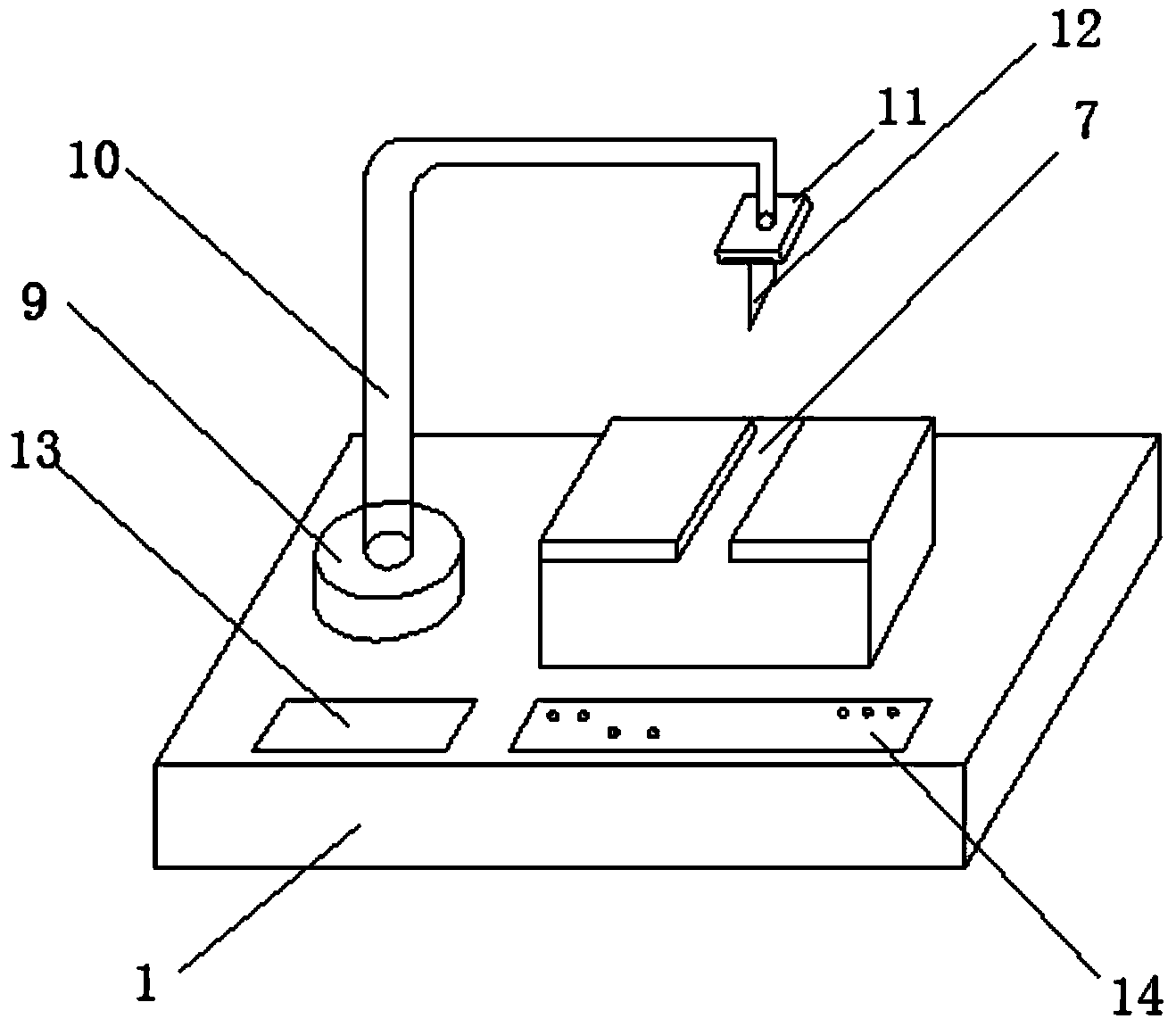

[0017] This embodiment discloses a waste electric wire stripping device, including a base 1 and a control mechanism, a clamping mechanism, and a cutting mechanism located on the base;

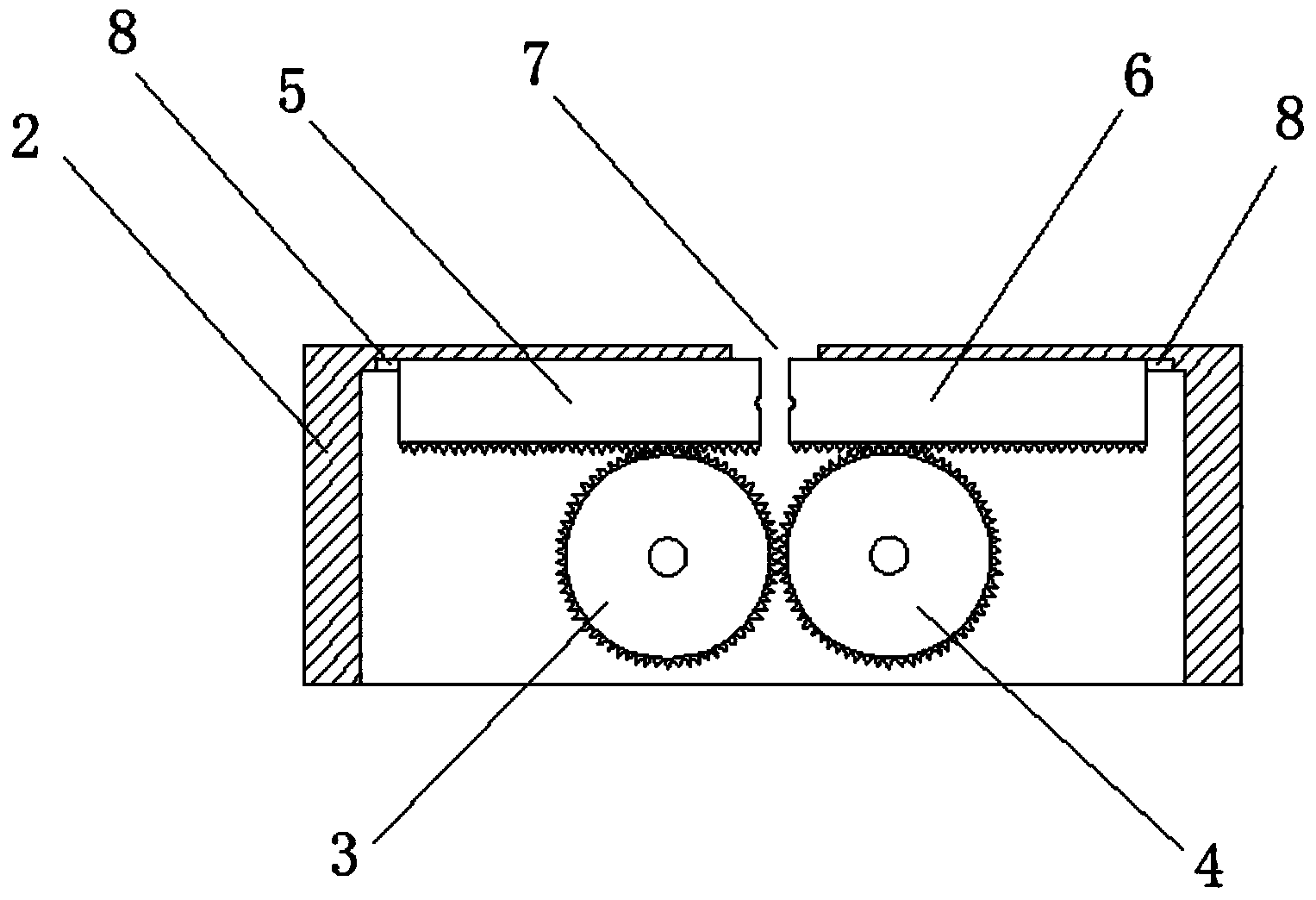

[0018] The clamping mechanism includes a housing 2, gear shaft one 3, gear shaft two 4, clamping block one 5, clamping block two 6; the housing includes a bottom plate, a top plate, and a Four side plates, the middle part of the top plate is provided with an opening 7, and the opening runs through the top plate longitudinally; the gear shaft 1 and the gear shaft 2 are symmetrically installed inside the housing with respect to the opening, and the two gear shafts are meshed and the axis direction is consistent with the opening. The pinion one described above is driven by a motor; the inner side of the top plate is symmetrically provided with a track 8 with respect to the opening, the clamping block one and the clamping block two are respectively arranged on the track, and the bottom surfaces of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com