A scalding device for poultry before slaughter

A poultry and scalding technology, which is applied in slaughtering, application, poultry processing, etc., can solve the problems of poor scalding effect and affect the depilation work, and achieve the effects of improving the scalding effect, preventing outward distribution, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

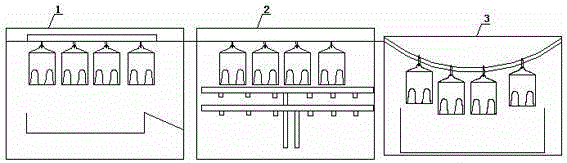

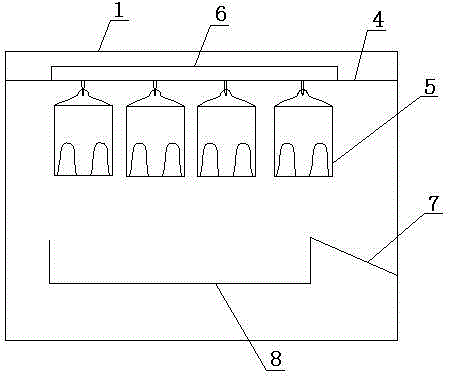

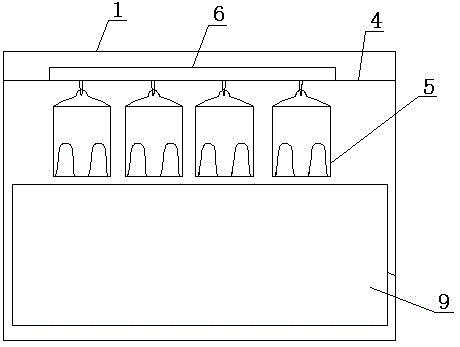

[0039] As shown in the figure, a scalding device for poultry before slaughter includes an electric shock chamber 1, a feather breaking chamber 2 and a scalding chamber 3. The poultry is hung upside down on a hanger 5, and the hanger 5 is hung on a transmission chain 4. The conveyor chain 4 for transporting poultry passes through the electric shock chamber 1 and the feather breaking chamber 2 in turn, and finally sends the poultry into the scalding chamber 3 for scalding;

[0040] The electric shock chamber 1 is provided with a conductive sheet 6 and a conductive battery 8 connected to the zero line. When the transmission chain 4 passes through the electric shock chamber 1, it contacts the conductive sheet 6. The conductive battery 8 is located below the transmission chain 4. The water is connected to the fire wire;

[0041] Outlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com