Multichannel high-pressure sprayer

A high-pressure nozzle and multi-channel technology, applied in fire rescue and other fields, can solve the problems of firefighters, such as troublesome, easy to lose, inconvenient to carry, etc., to achieve the effect of ensuring personal safety, reducing losses, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

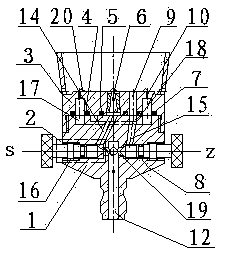

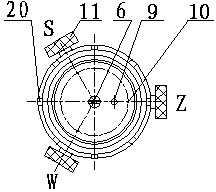

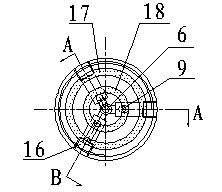

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 8 Shown is a multi-channel high-pressure nozzle, which includes a nozzle body 1, a water flow control valve 2 and a nozzle cover 3. The nozzle body 1 is funnel-shaped, and there are main water flow channels 12 in the vertical direction, which are evenly distributed in the circumferential direction. There are three threaded holes 16 for assembling the water flow control valve 2, through which the three water flow control valve handles 11 independently control the atomization injection mode, the columnar injection mode and the fan-shaped injection mode; the water flow control valve 2 includes the atomization water flow control valve , a cylindrical water flow control valve and a fan-shaped water flow control valve, wherein the atomized water flow control valve is composed of a threaded hole 16, a cylindrical hole 19, a main flow channel 12, an O-ring 8 of the water flow control valve and a handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com