Multi-point dispensing device combined to a dispenser

A combination point and glue dispensing technology, which is applied to the surface coating liquid device, spray device, spray device, etc., can solve the problems of long working time and difficulty in adjusting the amount of glue dispensed, and achieve the effect of fine operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The advantages, features and methods for realizing the present invention will be clearly explained in the following detailed embodiments in conjunction with the accompanying drawings. However, the present invention should not be limited to the following embodiments. The present invention can be realized in various forms that are different from each other. The embodiments of this specification are only to fully disclose the present invention so as to let those who have ordinary knowledge in the technical field of the present invention With a full appreciation of the scope of the invention, the invention can only be defined by the appended claims. The same symbol in the specification represents the same constituent element.

[0029] The multi-head dispensing combined with a dispensing machine of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

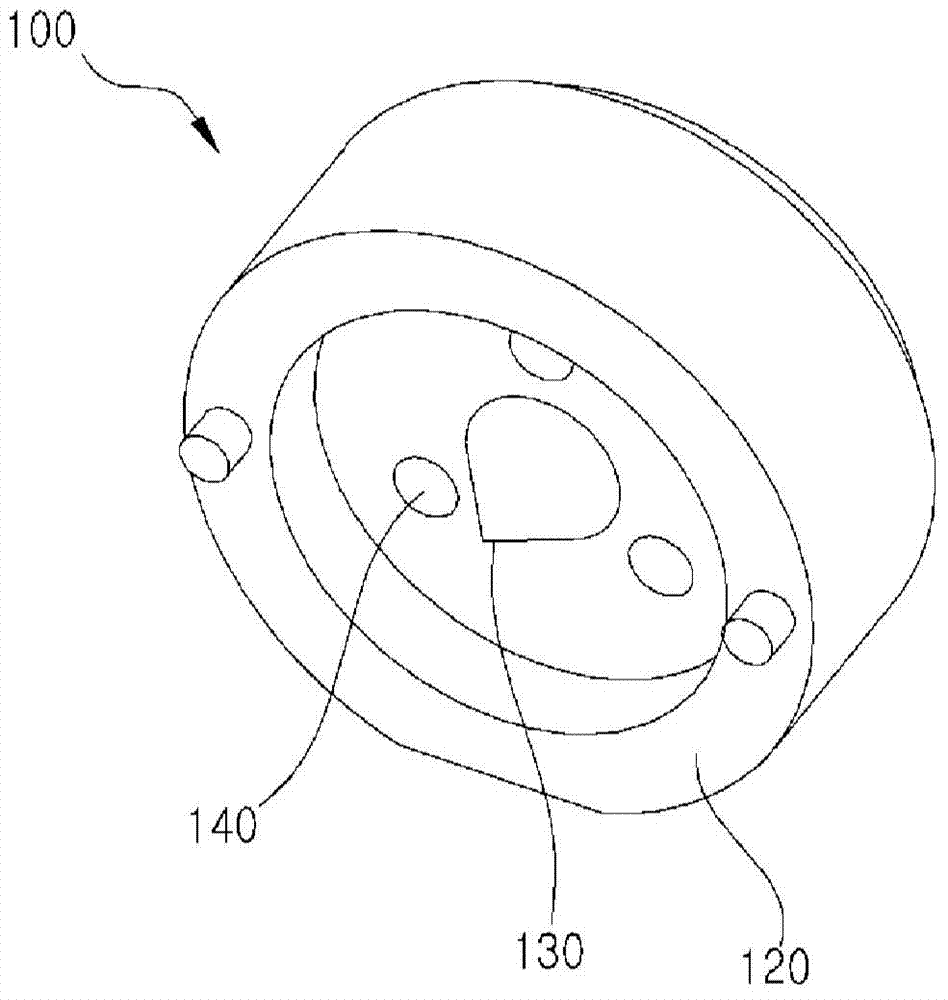

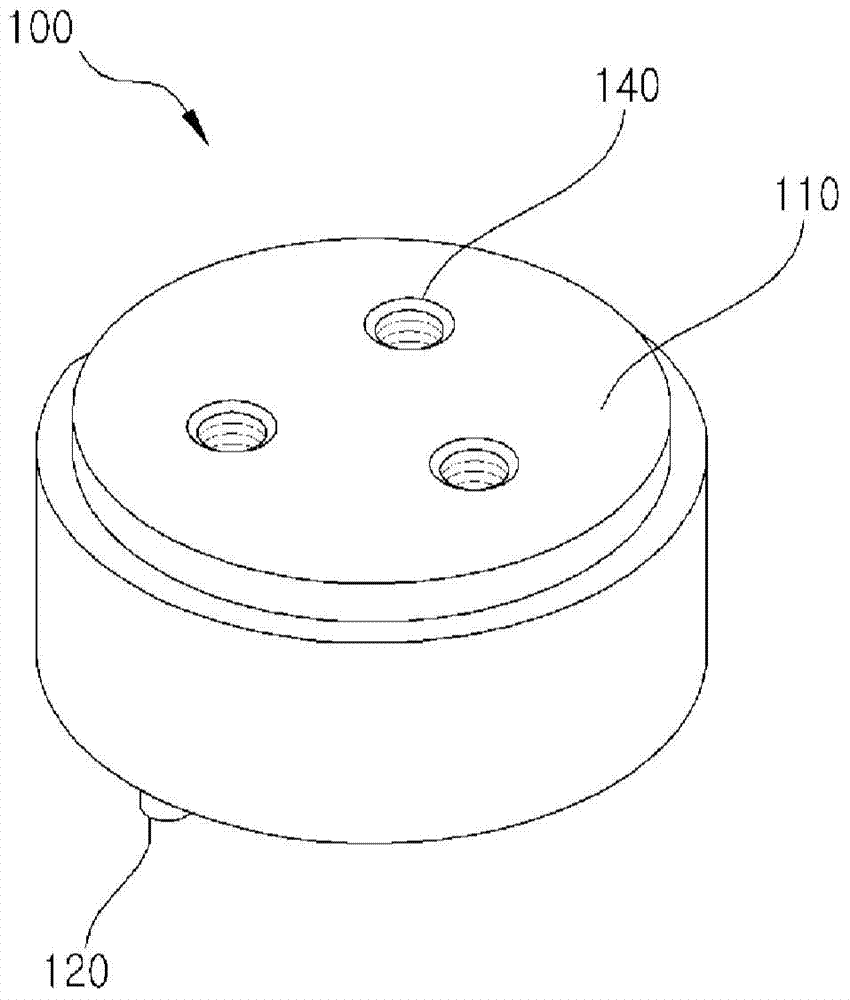

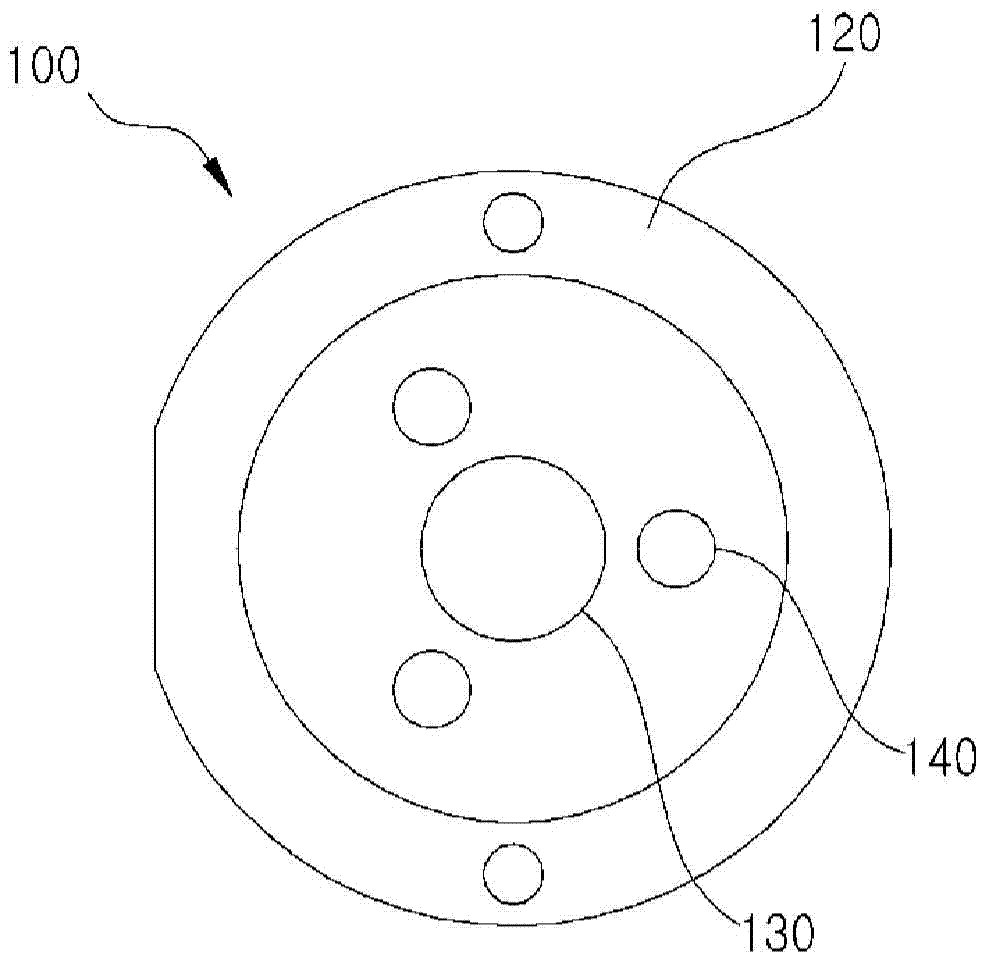

[0030] figure 1 It is an oblique view of multi-head disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com