Mixed steel ball sizer

A filter and steel ball technology, applied in the field of filter, can solve the problems of high friction force, low efficiency, scratches and so on of steel ball extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

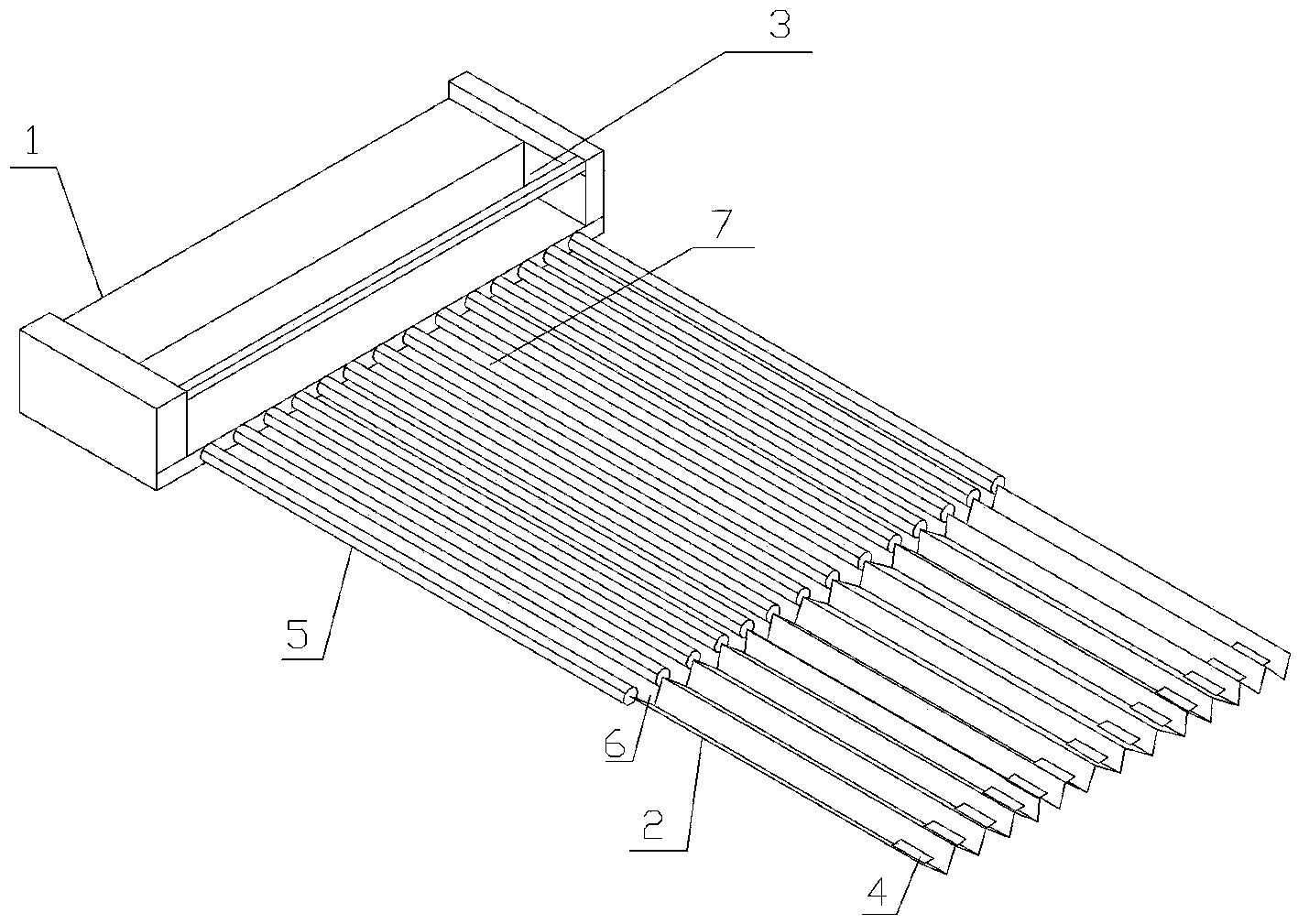

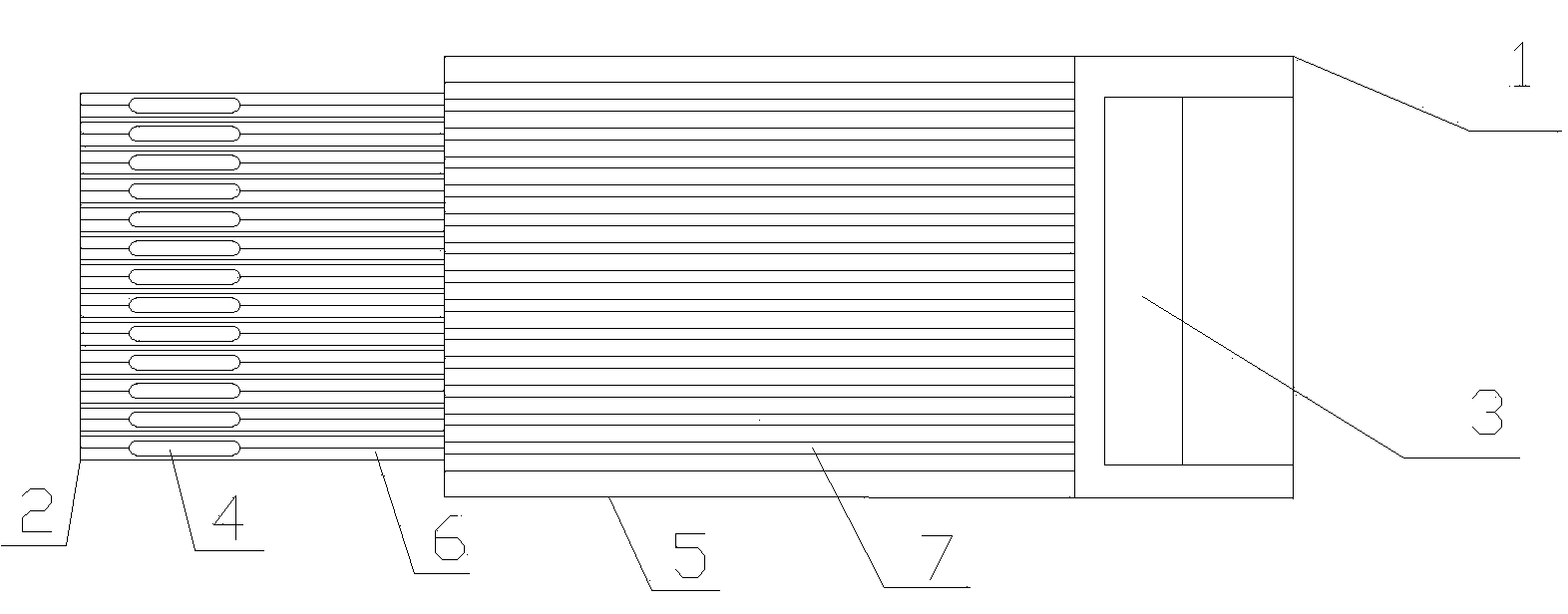

[0022] like figure 1 , figure 2 As shown, the steel ball mixed ball screen includes a sorting plate 1, a sorting groove 2, and a diversion groove 5. The sorting plate 1 is provided with a sorting opening 3, and the width of the sorting opening 3 is greater than the diameter of the steel balls to be sorted. , the length of the sorting opening 3 is equal to the length of the mixed ball sorting plate, one end of the diversion groove 5 is connected with the sorting opening 3 of the sorting plate 1, the other end of the diversion groove 5 is connected with the sorting groove 2, and the diversion groove The vertical position where one end of the 5 meets the sorting opening 3 of the sorting plate 1 is higher than the junction of the other end of the diversion groove 5 and the sorting groove 2, and the sorting groove 2 is a plurality of openings 6 that are upward and parallel to each other. The V-shaped groove is assembled, and the bottom of the V-shaped groove is provided with a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com