Ultrasonic trash can cleaning device and cleaning method thereof

A cleaning device and ultrasonic technology, applied in the field of cleaning, can solve problems such as poor cleaning effect, low degree of automation, and complex structure, and achieve the effects of uniform bubbles, high cleaning efficiency, and strong penetration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

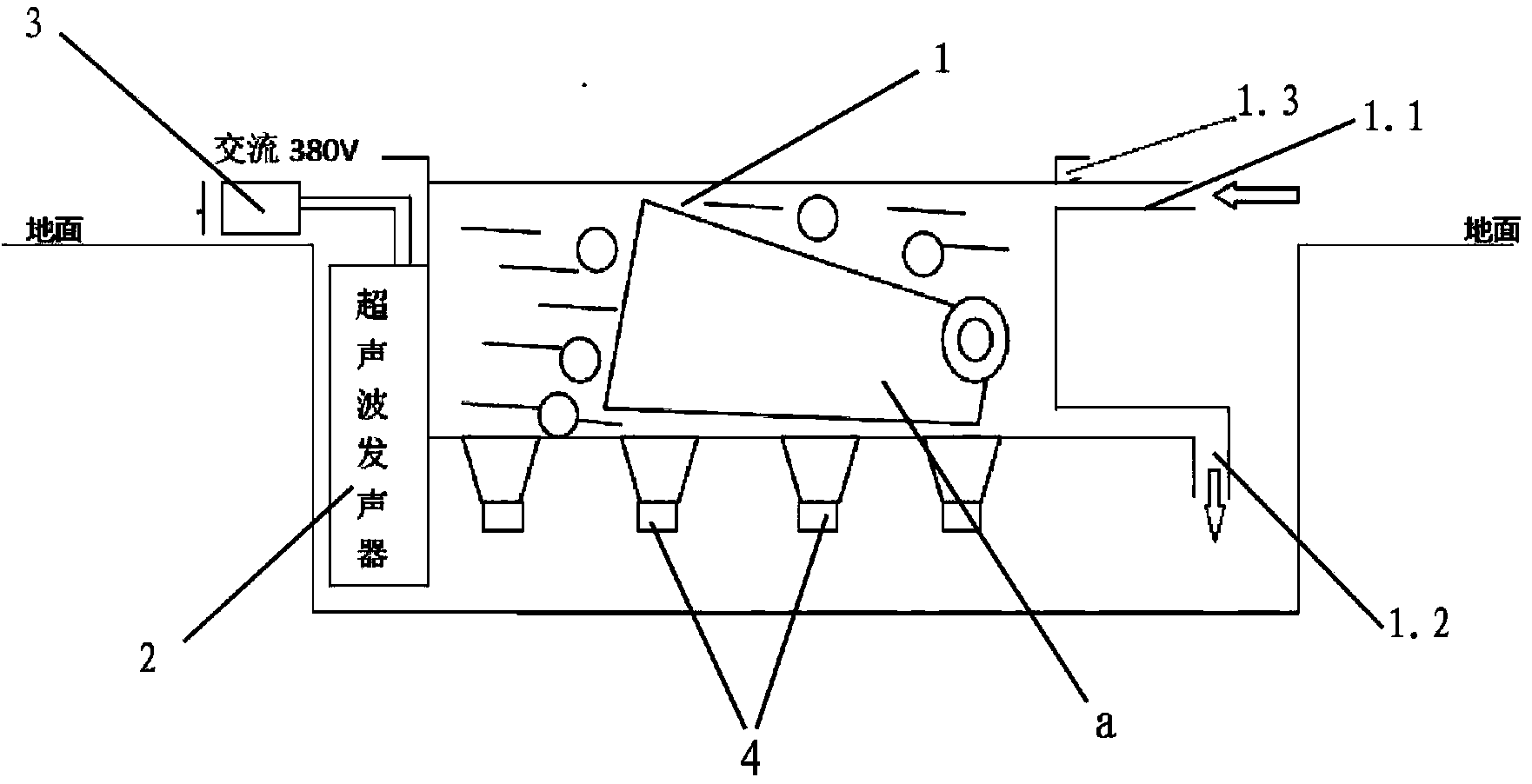

[0027] Such as figure 1 , the ultrasonic trash can cleaning device among the present invention, it is arranged below horizon, comprises cleaning tank 1, the cleaning cavity that constitutes in cleaning tank 1, cleaning liquid is provided in cleaning cavity, is provided with ultrasonic sounder at the side position of cleaning cavity 2. There are 130 transducers 4 at the bottom of the cleaning chamber. The cleaning tank 1 is made of stainless steel. The cleaning tank 1 includes a water inlet 1.1 and a water outlet 1.2. A guardrail 1.3 is provided at the top of the cleaning tank 1 . A transducer 4 is arranged at the side of the cleaning tank 1, and a thermometer, a drainage pump or a heater are also arranged in the cleaning tank 1. The placement of the above-mentioned equipment can be determined according to self-design.

[0028] During operation, inject warm water into the cleaning chamber, keep the water temperature at about 50 degrees, and then add the cleaning agent trichlo...

Embodiment 2

[0031] In this embodiment, the operation method is as follows: inject warm water into the cleaning chamber, keep the water temperature at about 65 degrees, then add cleaning agent acetone; put the garbage can into the cleaning chamber, soak the garbage can with the cleaning solution for 90 seconds; start the cleaning tank The transducer at the bottom, and start the ultrasonic sounder, set the transmission frequency to 30KHZ and the power density is 0.9w / cm 2 , turn on the ultrasonic sounder for 2 minutes; then turn off the ultrasonic sounder for 30 seconds, set the transmission frequency to 35KHZ, and the power density to 1.2w / cm 2, , start the transducer on the side of the cleaning tank, turn on the ultrasonic sounder for 3 minutes; turn off the transducer at the bottom of the cleaning tank, set the ultrasonic sounder’s emission frequency to 20KHZ, and the power density to 0.4w / cm 2 , turn off the power, lift the trash can a, and rinse the cleaning solution with clean water. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com