Installing machine of flip product rotating dowel and installing method thereof

An installation method and a technology of rotating pins, which are applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low installation efficiency, low yield, pin hole cracking, etc., and improve installation efficiency and coaxiality The effect of high consistency with the product and stable pin attachment depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

[0018] In order to adapt to the needs of factory production automation and improve the efficiency and yield of pin installation, after studying the entire process of pin installation, it is recognized that the alignment, positioning, and thrust during the initial installation of the pin and the installation position are the main factors. The direction of solution, the present invention has carried out brand-new and comprehensive design in conjunction with these aspects.

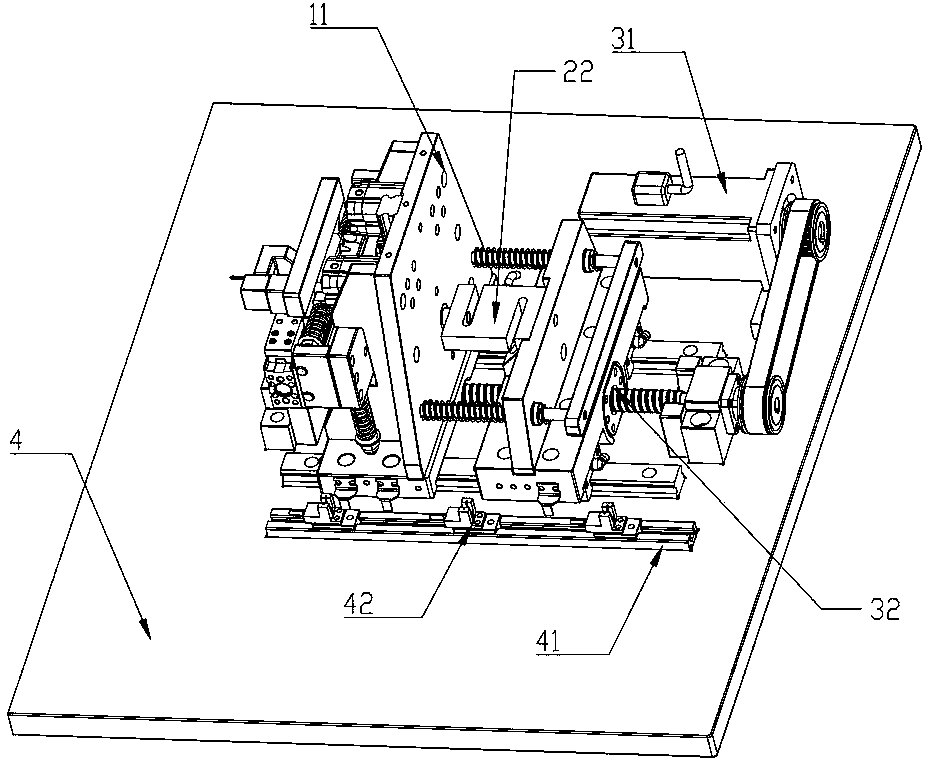

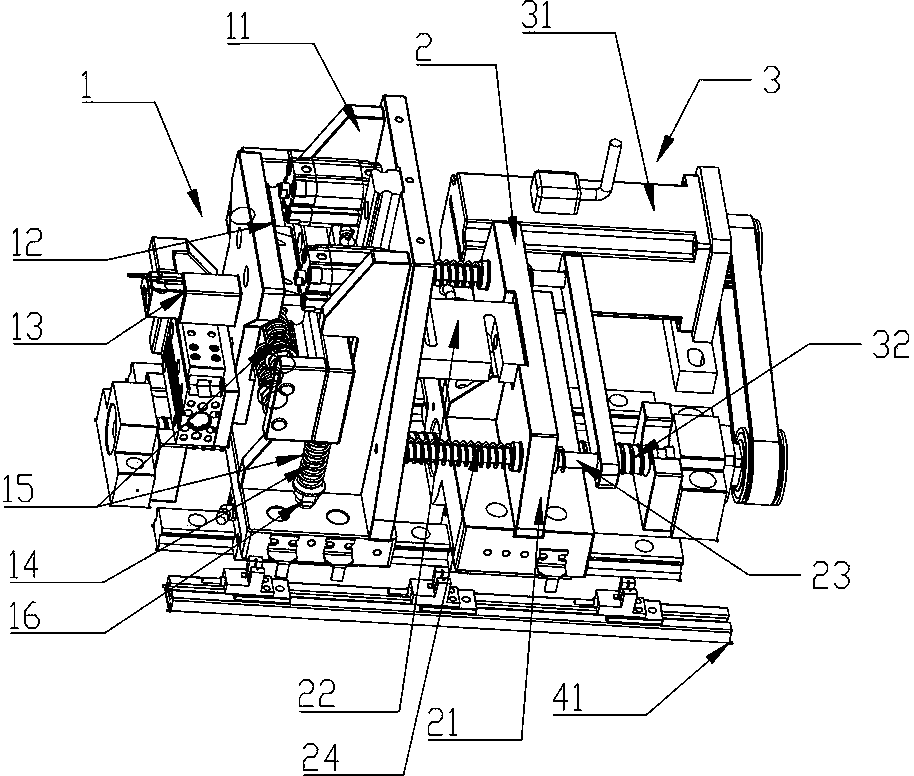

[0019] First understand the composition of the installation machine from the perspective of structural composition, such as figure 1 and figure 2 Shown is a schematic diagram of the assembly structure of the mounting machine of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com