Pneumatic trimming equipment for automobile interior trim part

A technology for automotive interior parts and equipment, which is applied in the field of pneumatic trimming and cutting equipment for automotive interior parts. High-quality trimming results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

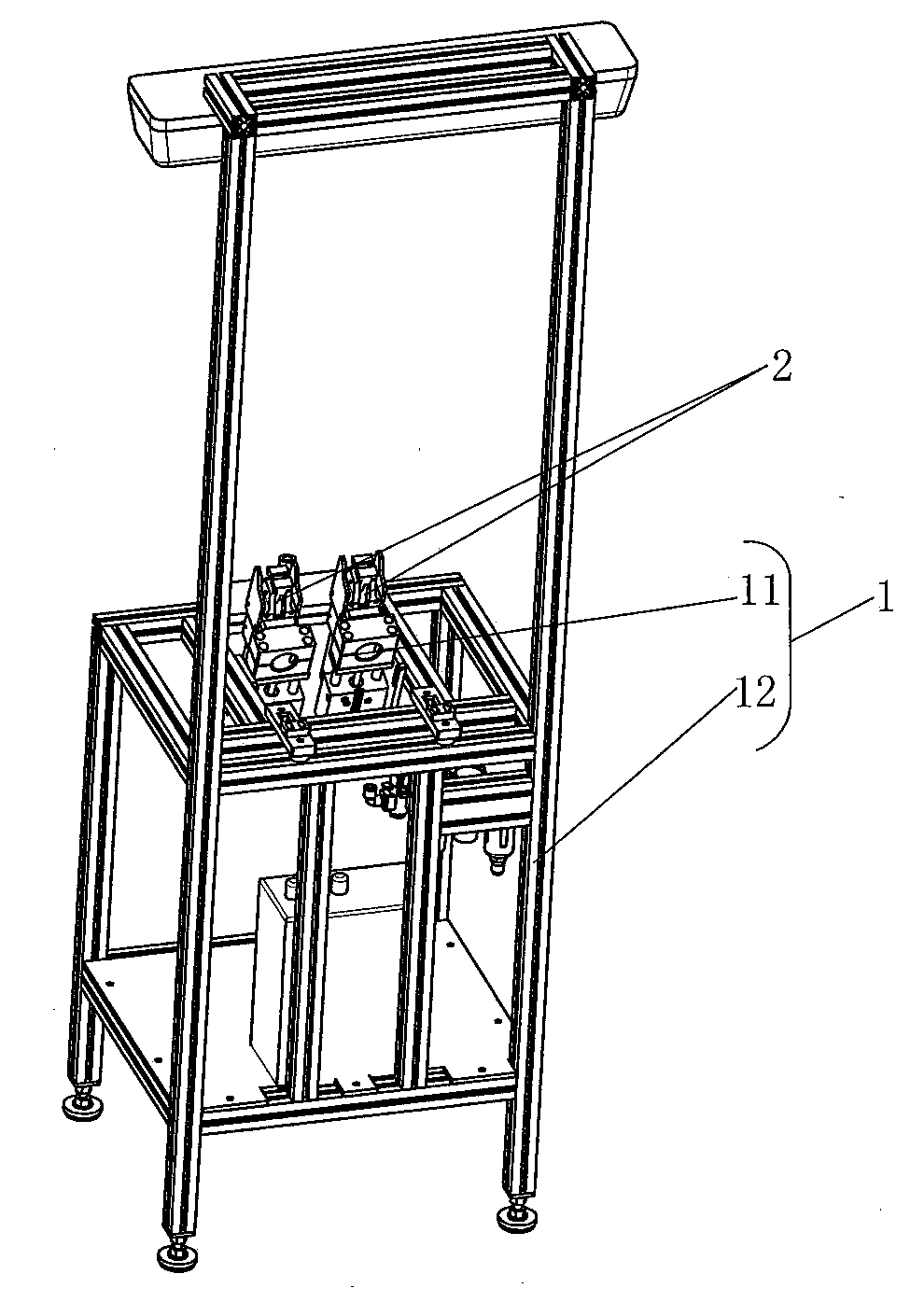

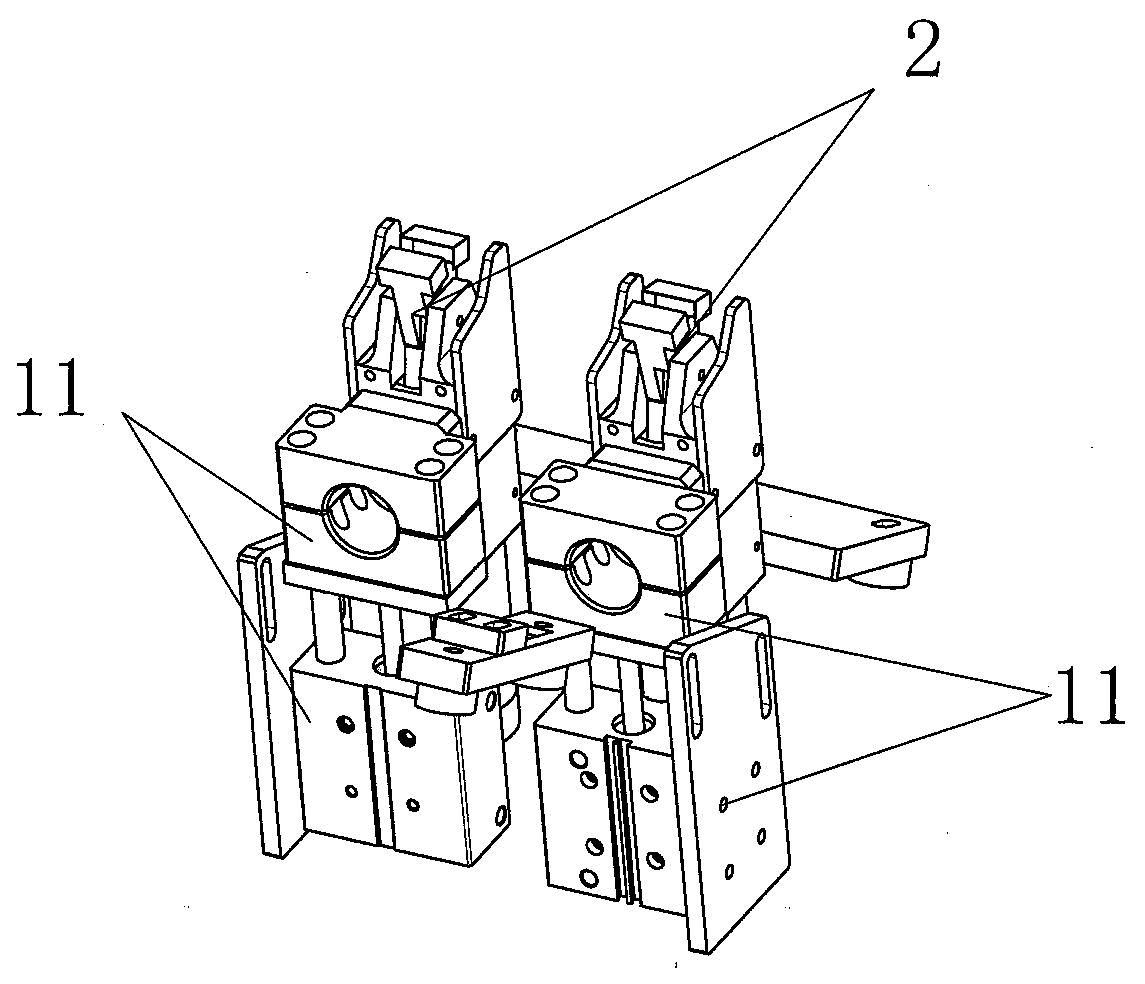

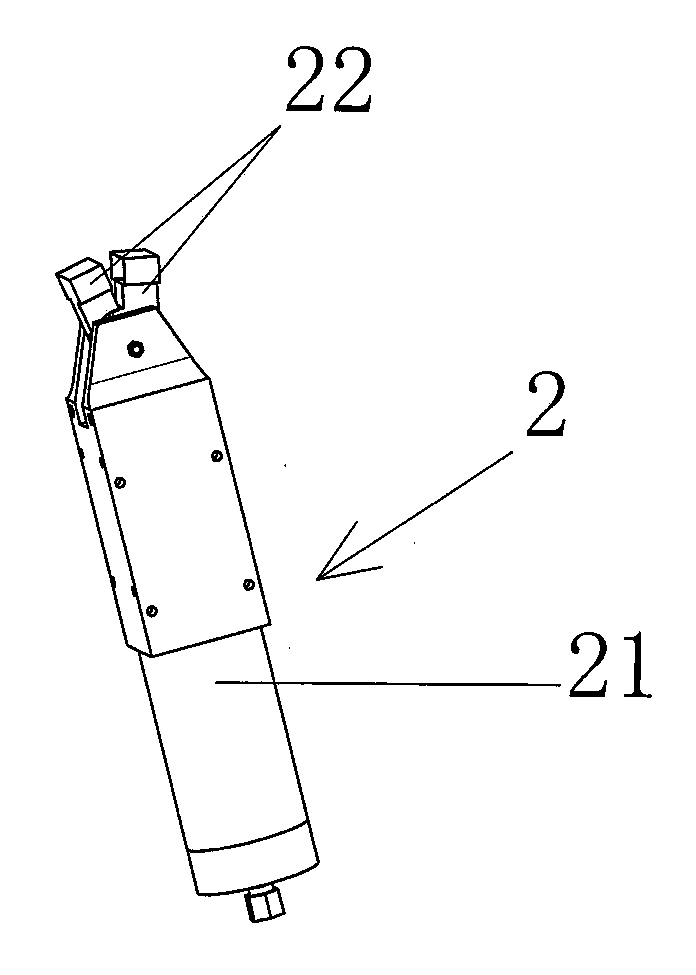

[0017] see figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention is made up of trimming fixture 1 and two trimming cutters 2, and trimming fixture 1 is made up of positioning mechanism 11 and support frame 12, and trimming cutter 2 is made up of pneumatic scissors 21 and scissors type trimming cutter head 22 Composition, the trimming cutter 2 is installed on the positioning mechanism 11, and the positioning mechanism 11 is fixed on the support frame 12, and the positioning mechanism 11 can move left and right and up and down on the support frame 12; Figure 4 As shown, the pneumatic scissors 21 are made up of a scissor trimming cutter head 22, a cutter body 23, a piston 24, a piston return spring 25, and a cutter head return spring 26. The cutter body 23 has a piston cylinder 27, and the piston 24 is located in the piston cylinder 27. , the middle of the piston 24 is provided with a V-shaped groove 241, the scissors-type trimming cutter head 22 is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com