Automatic switching mechanism for universal movement and directional movement of cart wheels

A technology of automatic conversion and directional movement, applied to trolleys, trolley accessories, motor vehicles, etc., can solve problems such as high product cost, easy damage, and complex design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

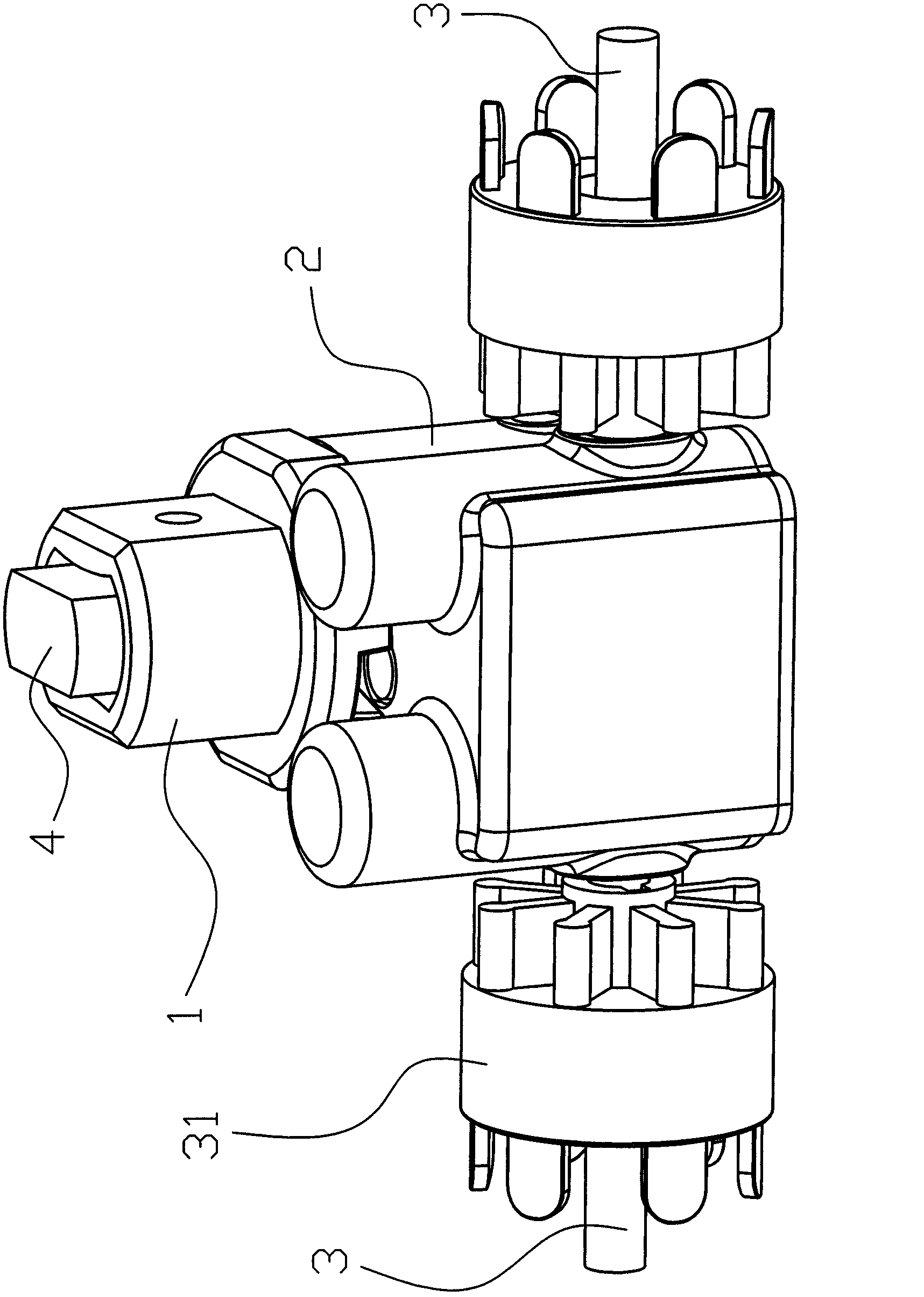

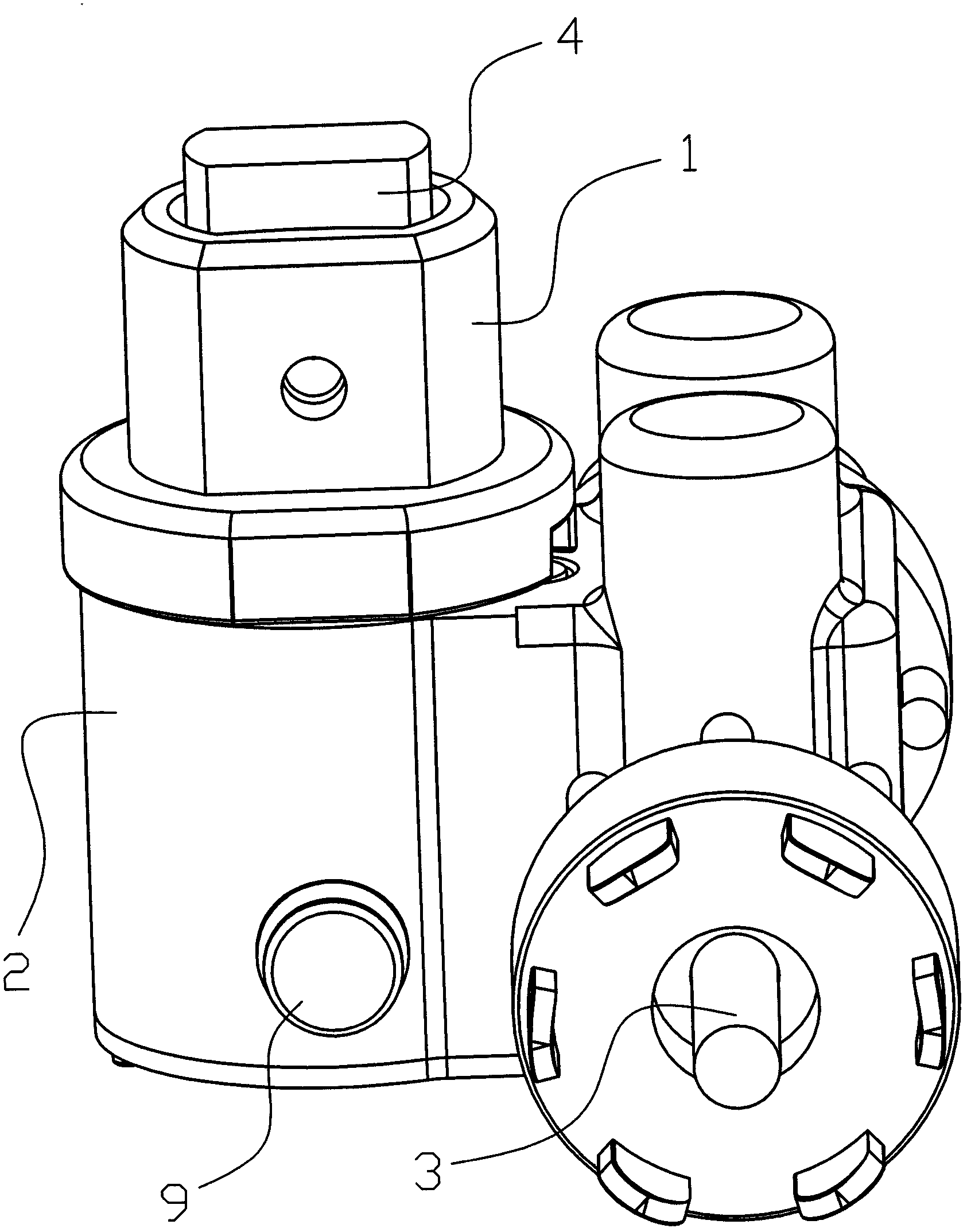

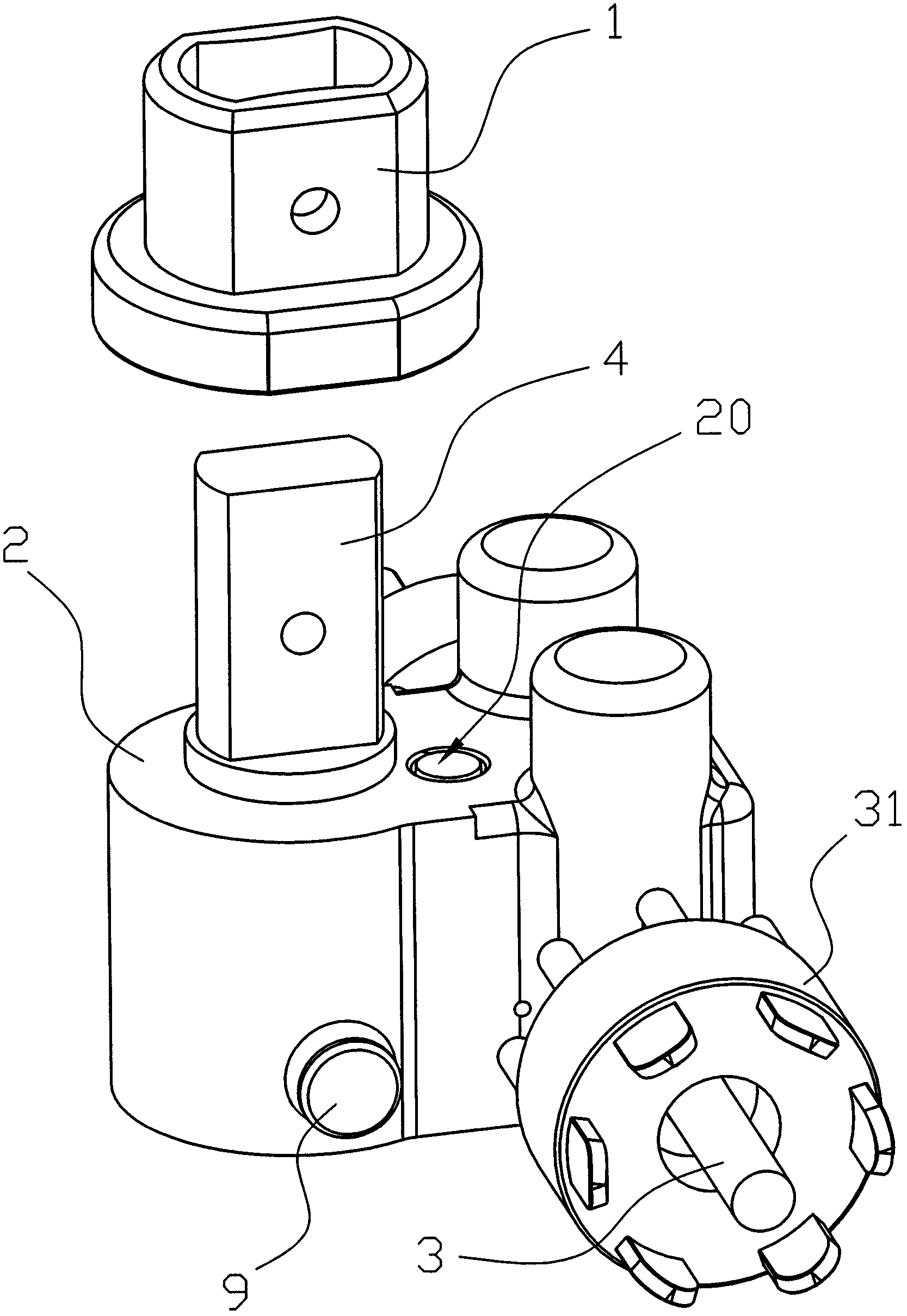

[0028] Such as Figure 1 to Figure 12As shown, the universal and directional automatic conversion mechanism of the trolley wheel in this embodiment includes an upper bracket 1, a lower bracket 2, and a rotating shaft 3 for connecting the wheels. The wheels are arranged on both ends of the rotating shaft 3, A wheel is fixed with the rotating shaft, and in order to fix the wheel with the rotating shaft 3 more conveniently, a wheel frame 31 is fixed on the rotating shaft 3, and the wheel is inserted together with the wheel frame 31 sleeves through the jack on the side and is fixed. The upper bracket 1 is fixed to the foot bar 4, the rotating shaft 3 is rotatably placed on both sides of the rear of the lower bracket 2, and the lower part of the foot bar 4 pushes up from the front of the lower bracket 2. The surface penetrates into the inner cavit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap