Universal deburring optical head device

A technology of bald head and mounting seat, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low processing accuracy and efficiency, low degree of integration, difficult to remove burrs, etc., and achieve the effect of improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

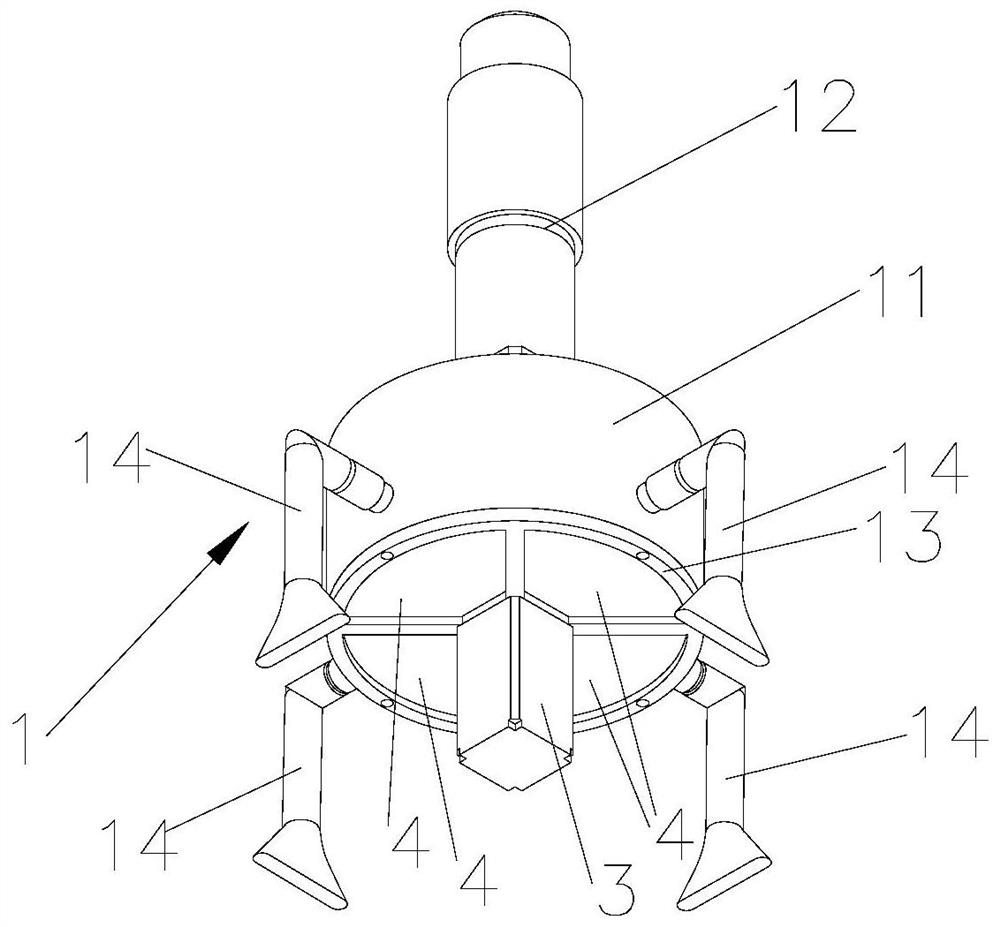

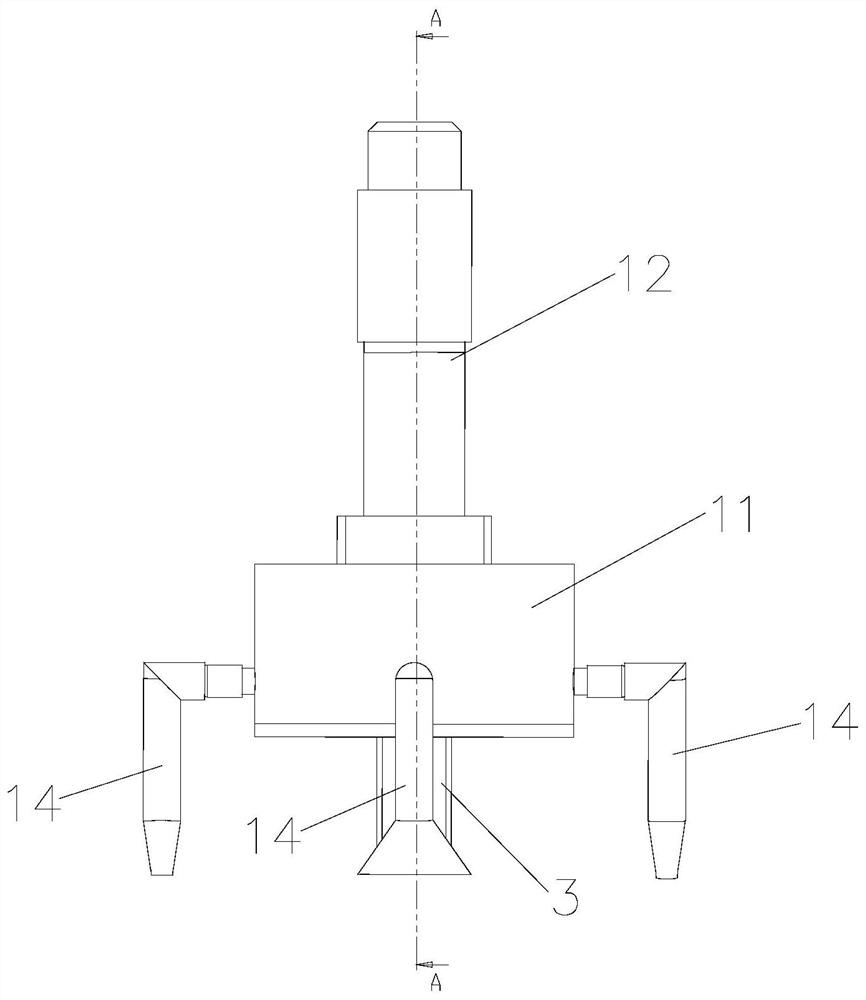

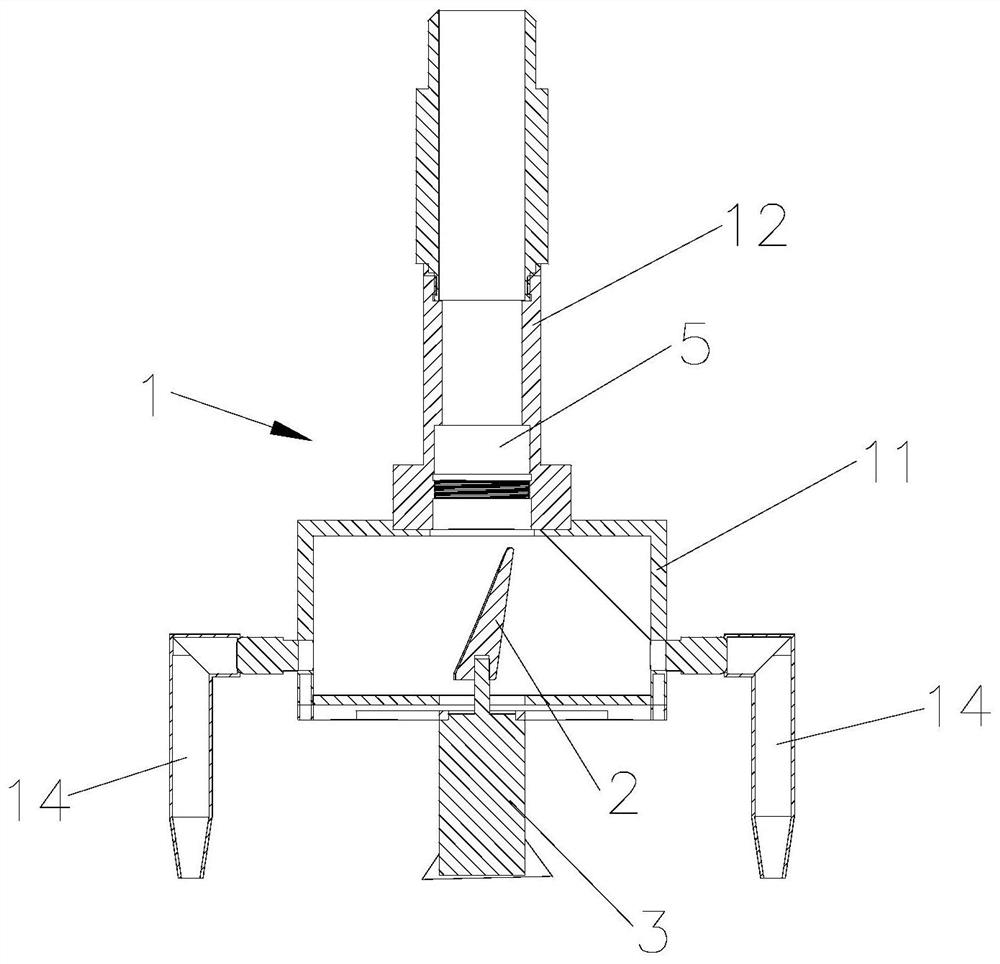

[0024] see Figure 1 to Figure 6 As shown, a kind of optical head device for universal deburring, the optical head device includes a bracket 1, a collimation system installed on the bracket 1, a parabolic mirror 2 that is rotatably connected to the bracket 1, and is used to drive the parabolic mirror 2 Rotary driving mechanism, wherein, the parabolic mirror 2 has a parabolic mirror surface 21, the parabolic mirror surface 21 is located on the light path of the collimation system, and the rotation center line of the parabolic mirror 2 is in line with the projection direction of the laser beam collimated by the collimation system parallel to each other.

[0025] Specifically, see image 3 , Figure 5 and Figure 6 As shown, the parabolic mirror 21 is slightly arched inward along the thickness direction of the parabo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com