A pipe cleaning robot

A technology of robot and robot body, applied in the field of robotics, can solve the problems of tree root removal, manual cleaning of debris that cannot be firmed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further explained in detail below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

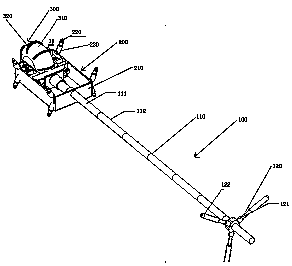

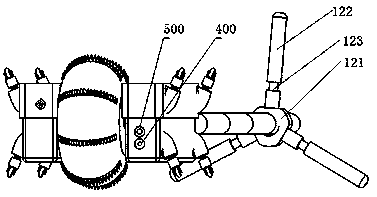

[0033] Such as figure 1 and figure 2 As shown, a pipe cleaning device in the present invention includes a semi-automatic manual propulsion device 100 and a robot body connected to the propulsion device 100. The robot body includes a grinding device 300, a flushing device, a lighting device 500, a visual device 400, a waterproof Fuselage, traveling mechanism 200, transmission device.

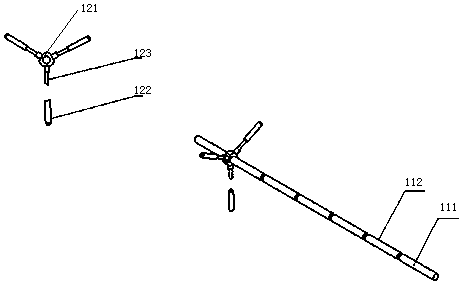

[0034] Such as image 3 As shown, the propulsion device 100 is composed of a splicable propulsion rod 110 and a chuck fixing device 120 . The splicable propulsion rod 110 is formed by connecting a plurality of rod bodies of the same specification, the number of required connecting rods 123 can be determined according to the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com