Phase change heat storage device based on condensation heat transfer and its key parameter determination method

A technology of phase change heat storage and heat transfer coefficient, which is applied in complex mathematical operations, cooling/ventilation/heating transformation, modification with liquid cooling, etc., can solve problems such as inability to match the heat storage needs of gas-liquid mixed refrigerants, and achieve The effect of enhanced heat conduction process, enhanced condensation heat transfer process, and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

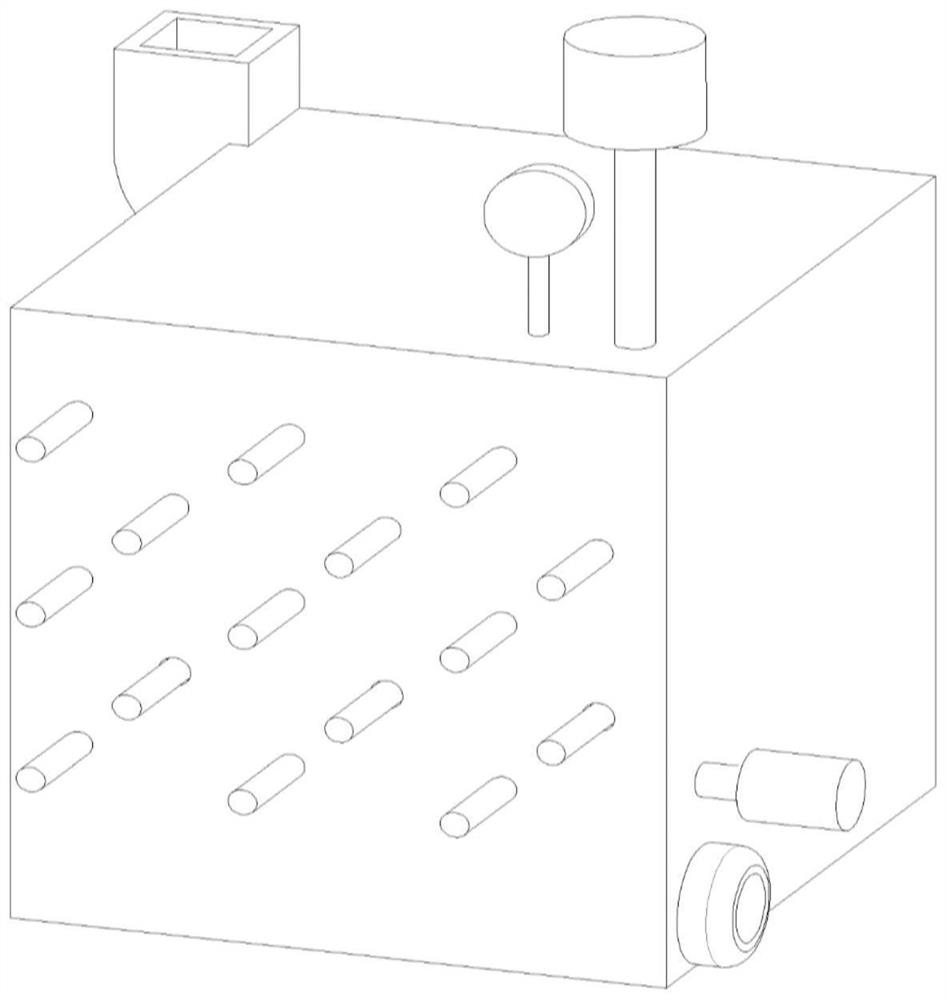

[0119] This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

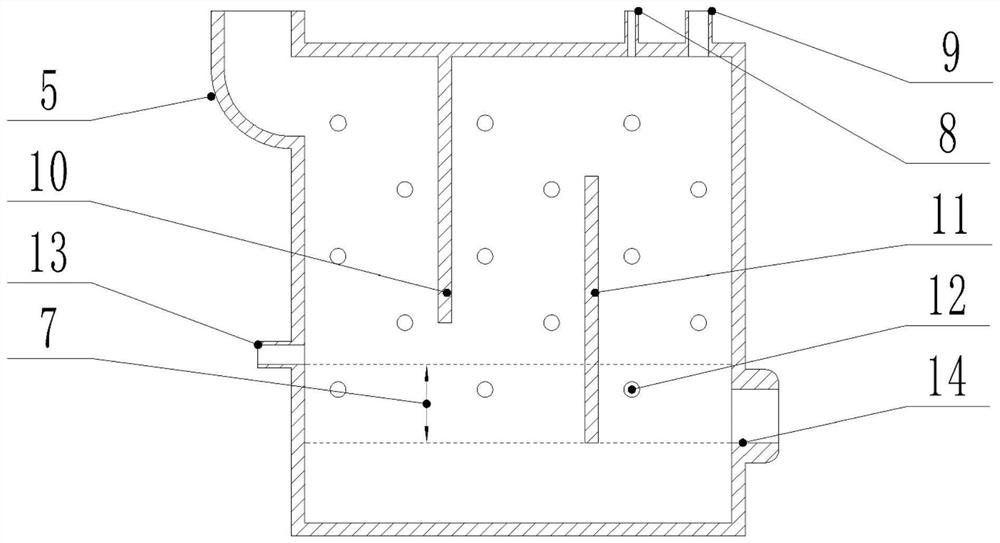

[0120] The design condition is a thermal load peak of 300kW for 6s with 100s interval. The input temperature of the steam inlet 5 is 10°C, and the input temperature of the inner heat exchange tube 1 is -25°C.

[0121] According to the above calculation steps, the parameter calculation of the phase change heat storage device is performed.

[0122] Step 1. Estimate and round to obtain the condensation point T of the phase change heat storage device 3 -10℃, phase transition point T 4 is -15℃;

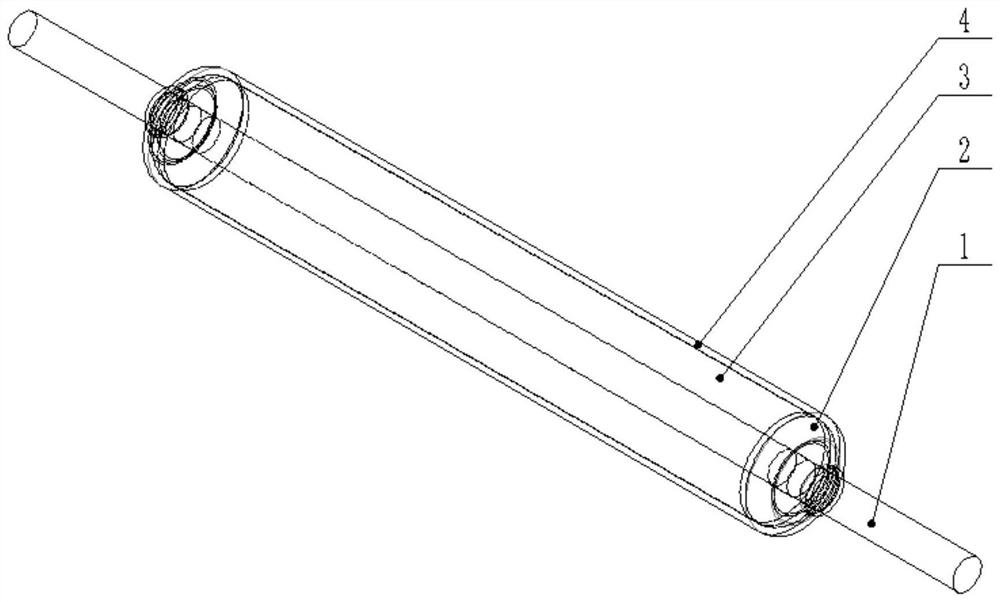

[0123] Step 2. Select the outer diameter d of the inner heat exchange tube 1 2 is 3mm, the calculated wall thickness t 1 is 0.25mm;

[0124] Step 3. It is calculated that the volume V of the phase change he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com