Printer rolling tension control method based on piecewise function curve

A tension control, piecewise function technology, applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problem of high core wrinkle rejection rate, and achieve the effect of solving core wrinkle and convenient operation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

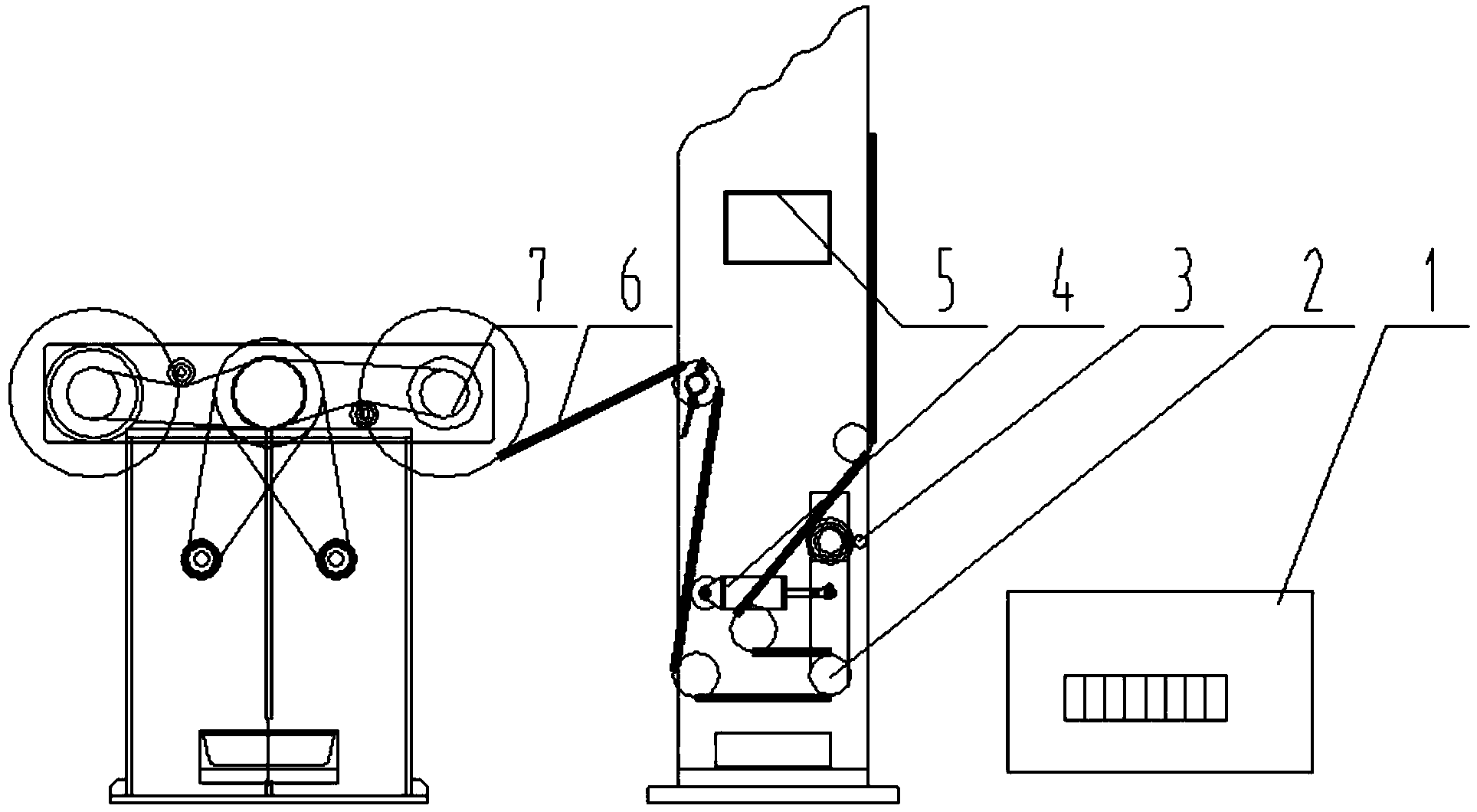

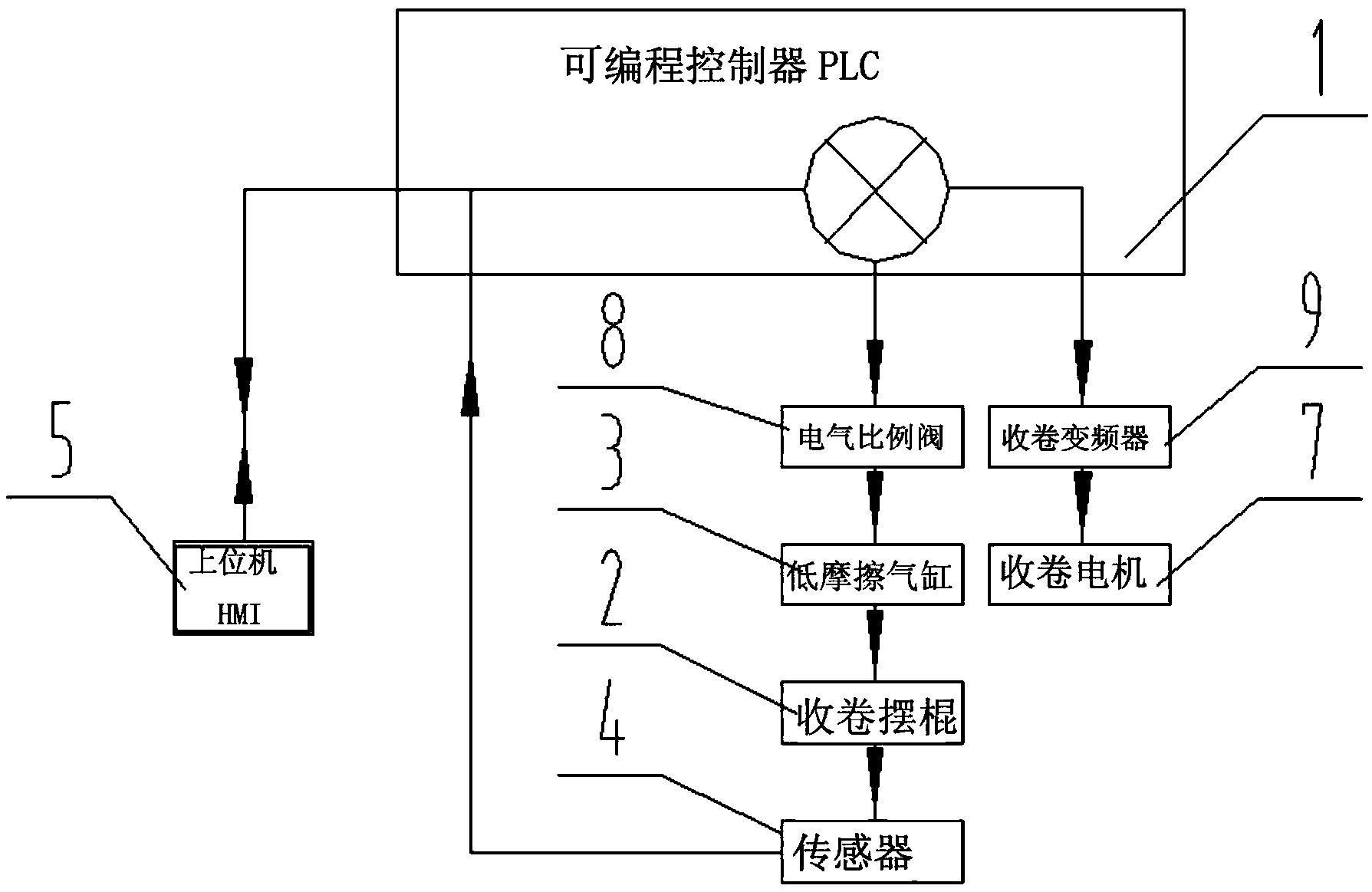

Image

Examples

Embodiment 1

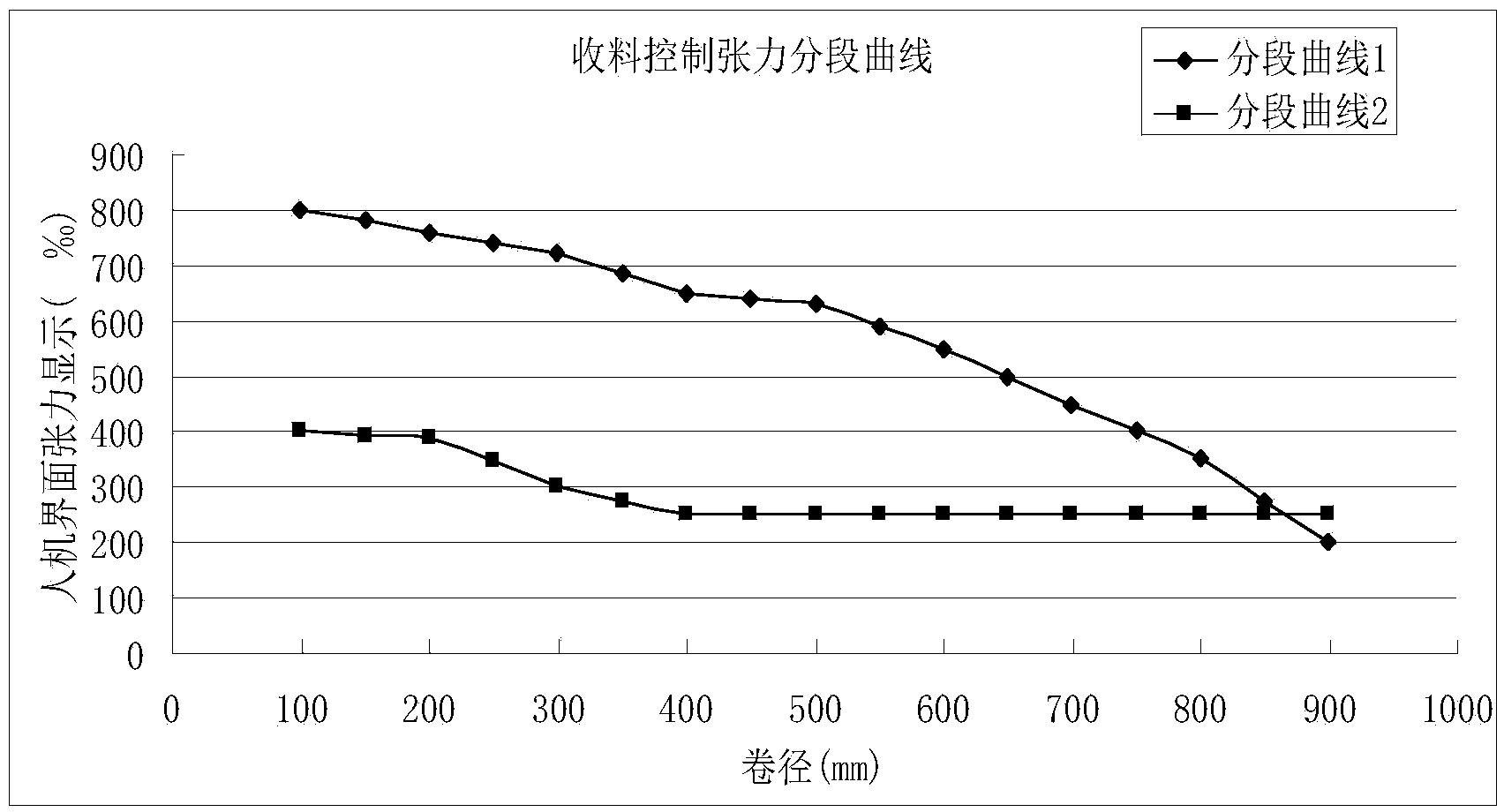

[0080] Partition according to the data of tension partition in the first row of the first row in Table 3, and select the parameters as follows, TS=650, DS=200.0, TE=350, DE=820.0, then as Image 6 The piecewise function control curve of tension can achieve the control effect of tension curve attenuation.

Embodiment 2

[0082] Partition according to the data of tension partition in the second row of the second row in Table 3, and select the parameters as follows, TS=650, DS=200.0, TE=350, DE=820.0, then as Figure 7 The piecewise function control curve of tension can achieve the control effect of linear tension attenuation.

Embodiment 3

[0084] Partition according to the data of tension partition in the third row of the third row in Table 3, and select the parameters as follows, TS=650, DS=200.0, TE=350, DE=820.0, then as Figure 7 The piecewise function control curve of tension can achieve the control effect of linear tension attenuation.

[0085]

[0086] table 3

[0087] from Image 6 , Figure 7 with Figure 8 It can be seen that the change law of the tension segment curve can be adjusted at any time according to the needs of practical applications, and the tension attenuation area of each section can be adjusted at any time according to actual needs. Segment curve, the display is intuitive and clear, and the operation is simple; the setting values are initial diameter, tension, end diameter, tension and tension at each segment end point, and it is convenient to control the entire tension decay process.

[0088] Therefore, the segmented curve taper tension control method of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com