Pan extractor

A horizontal rotary extractor and leaching technology, which is applied in the direction of fat production, fat oil/fat production, etc., can solve the problems of large steam consumption, low concentration of mixed oil, and high residual oil, so as to save process flow and enhance spraying efficiency , The effect of oil level reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

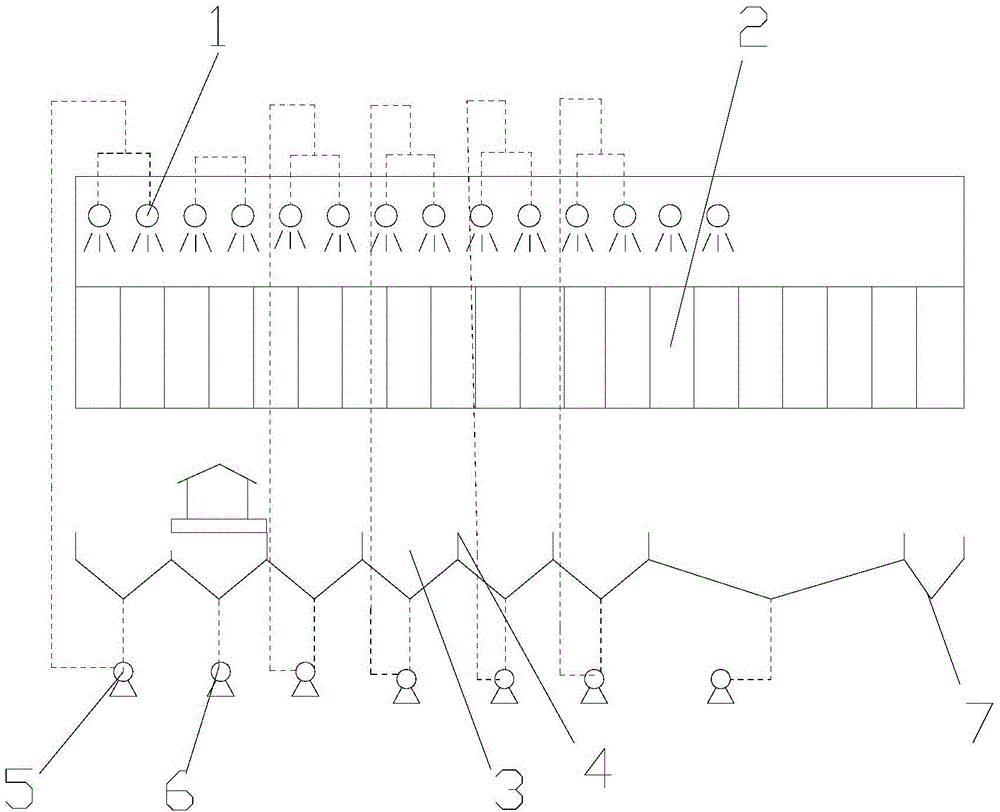

[0014] The horizontal rotation extractor provided by the present invention is cylindrical, and its internal structure is laid out as follows: figure 1 As shown, its main oil spray pipe 1, 20 leaching rotary grids 2, 7 oil collecting grids 3 and mixed oil circulating oil pump 5 are composed. Each oil-collecting grid 3 is separated by an oil-collecting grid partition 4 (the partition between the first and second oil-collecting grids 3 is very low, and is actually in a connected state, which can also be regarded as a grid).

[0015] There are 14 spray pipes 1 in total, of which the first 12 are sprayed with mixed oil, the last two are sprayed with fresh solvent, and the 14 spray pipes 1 are evenly distributed in the range of 0-270° abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com