A method for noise reduction using profile barrier

A profile and barrier technology, applied in the field of noise reduction, can solve the problems of obstructing the sight of the landscape, using many materials, and heavy structural load, and achieving the effect of good noise reduction, noise reduction, and small structural load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

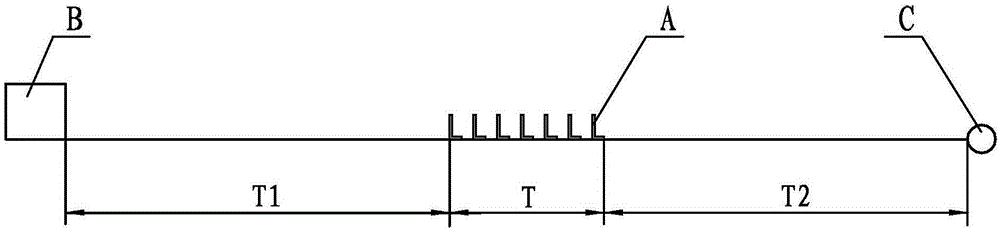

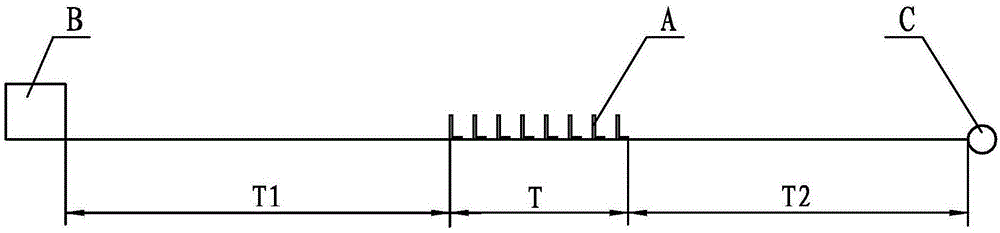

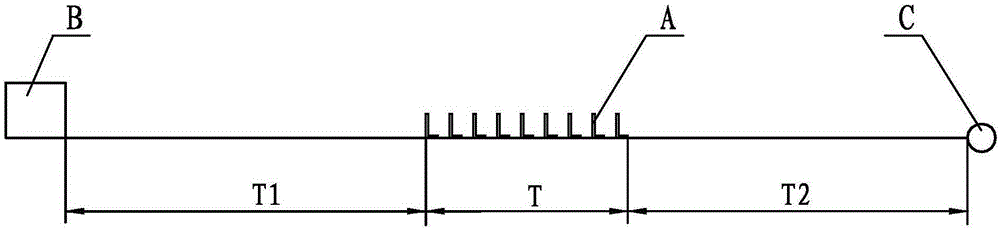

[0030] Specific implementation mode 1: Combination Figure 1-9 To describe this embodiment, this embodiment is implemented through the following steps:

[0031] Step 1. Make profile barrier A: Place seven profiles at equal intervals in sequence, and the outer length T of the seven profiles is 1.8m;

[0032] Step 2. Place the profile barrier A at the sound source B and the receiving point C: Place the profile barrier A on the ground parallel to the road in step 1, and between the sound source B and the receiving point C, the starting point of the profile barrier A The distance T1 to the sound source B is 5m-6m, and the distance T2 from the starting point of the profile barrier A to the receiving point C is 5m-6m;

[0033] Step 3. Noise reduction test: Use a sound level meter to perform a noise test on the profile barrier A formed by seven profiles at the receiving point C, and record the sound pressure level at the receiving point C as N1, see figure 1 ; The sound level meter is a co...

specific Embodiment approach 2

[0043] Specific implementation manner two: combination figure 1 To illustrate this embodiment, in this embodiment, the material of the profile in step one is metal material or concrete, and the metal material can be aluminum alloy, copper, iron or zinc. These materials can avoid resonance and the materials are durable. The other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0044] Specific implementation mode three: combination figure 1 To describe this embodiment, the profile is angle steel, L-shaped, channel steel, dovetail or rectangular. The other steps are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com