A three-dimensional wind and raincoat and its production process

A wind and raincoat, three-dimensional technology, applied in the field of functional clothing, can solve the problems of poor air permeability, uncomfortable wearing, weak weatherproof function, etc., and achieve the effects of reducing wind resistance, simple structure and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

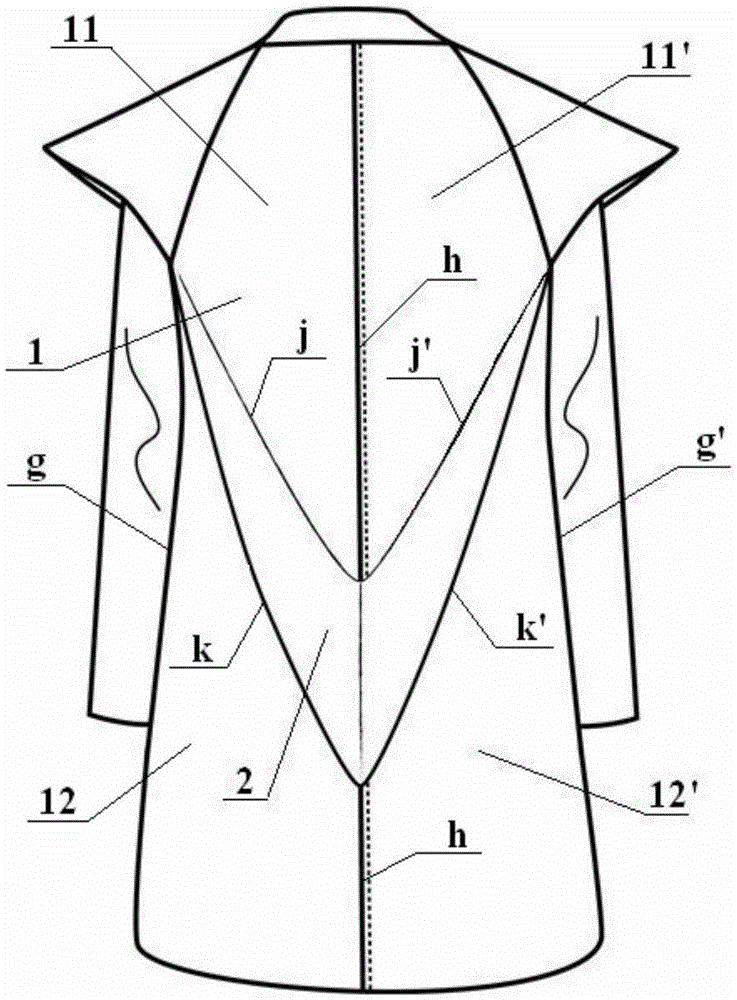

[0038] image 3 Shown is a three-dimensional raincoat provided in this embodiment with the triangular three-dimensional insert 2 of the present invention provided on the rear panel of the raincoat body 1 .

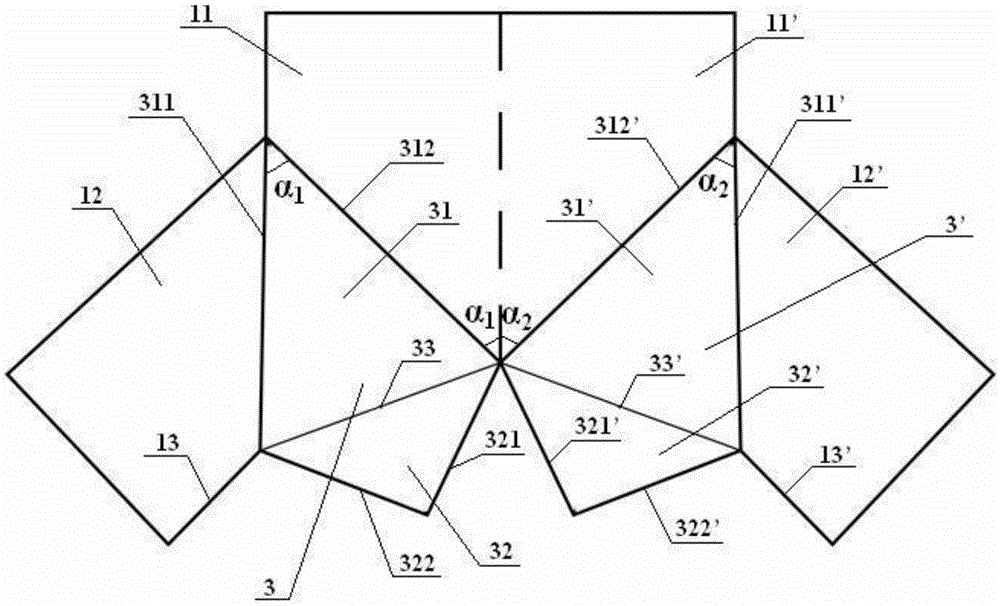

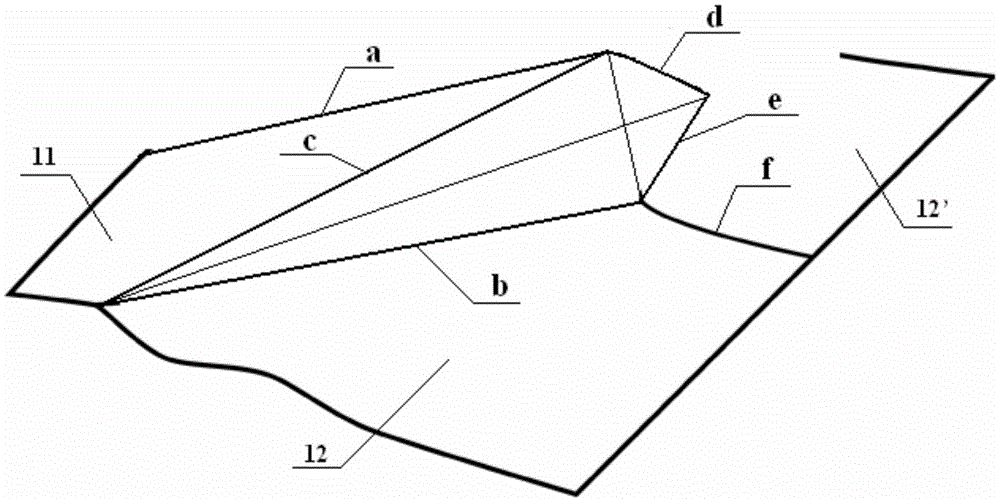

[0039] combine image 3 and Figure 4 As shown: the triangular three-dimensional insert 2 is composed of two left triangular plane inserts 3 and right triangular plane inserts 3' that are completely equal in size, wherein the left (right) triangular plane insert 3 (3') The dividing line located (coinciding with j / j') is between the back waist dart line g(g') and the back midline h, and the angle α formed with the back midline h 1 (α 2 ) is an acute angle. The j (j') line among the figure is the seam line of the waist of the large isosceles triangle of the left (right) triangular plane inserting sheet 3 (3 ') of the rear panel and the upper partition sheet 11 (11 ') of the left (right); k (k ') is the vertex diagonal line of the left (right) triangular plane inserting ...

Embodiment 2

[0042] Figure 5 Shown is a three-dimensional raincoat provided in this embodiment with the triangular three-dimensional insert 2 of the present invention provided on the front panel of the raincoat body 1 .

[0043] combine Figure 5 and Figure 6 As shown: the triangular three-dimensional insert 2 is composed of two left triangular planar inserts 3 and right triangular planar insert 3' that are not completely equal in size, but constitutes the left triangular planar insert 3 and the right triangular planar insert The sizes of the small isosceles triangles at 3' are completely equal; and the dividing line where the left triangular plane insert 3 is located (coinciding with p) is between the front waist dart line m and the front chest dart line n and is in line with the front chest dart line Angle α formed by line n 1 It is an acute angle; the dividing line where the right triangular plane insert 3' is located (coincident with p') is between the turning point o of the lapel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com