Semi-dry desulfurization device and method

A semi-dry desulfurization and desulfurization device technology, applied in the field of flue gas desulfurization, can solve the problems of low desulfurization efficiency, low sliding speed, easy caking of the absorption tower, etc., achieve high desulfurization efficiency and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

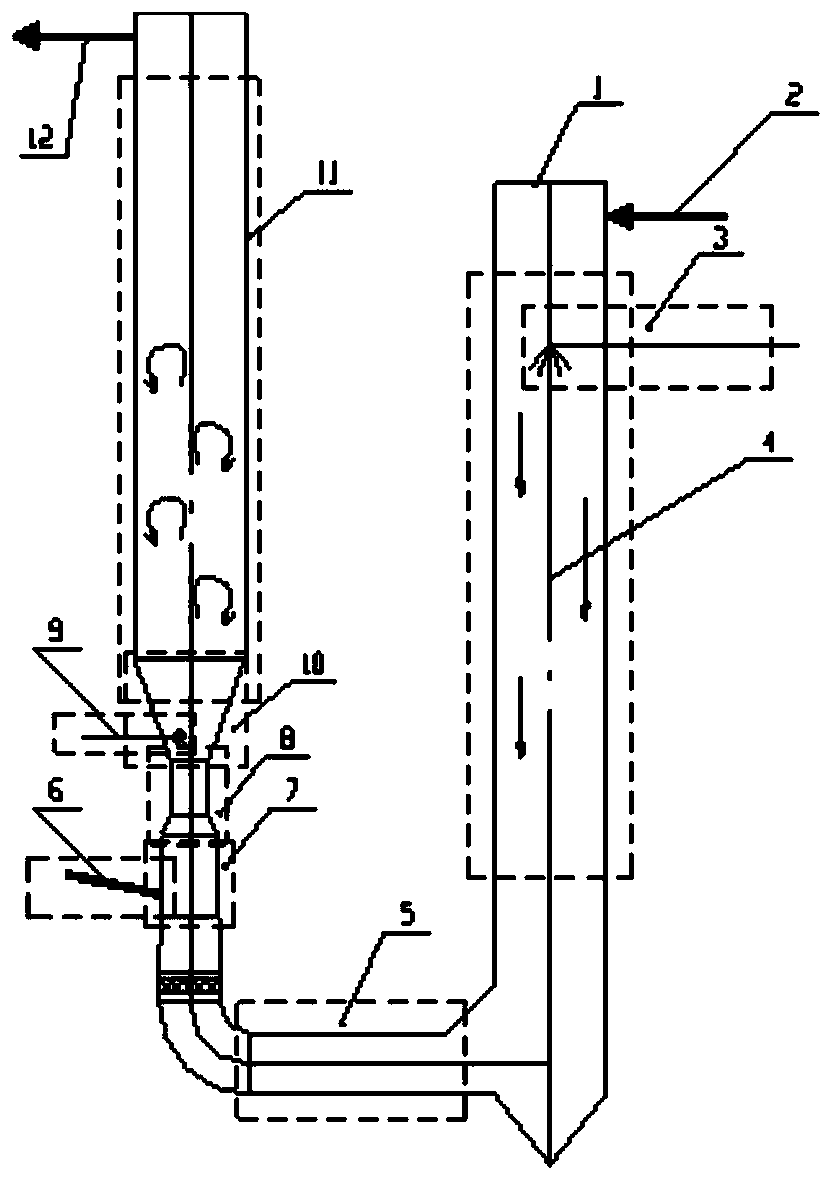

[0075] For the structural schematic diagram of the semi-dry desulfurization device provided in Example 1 of the present invention, see figure 1 As shown, 1 is the casing of the desulfurization device, 2 is the flue gas inlet, 3 is the slurry (lye) spray device, 4 is the semi-dry slurry desulfurization section, 5 is the horizontal flue gas rectification section, and 6 is the Feeding inlet, 7 is the feeding secondary desulfurization section, 8 is the Venturi acceleration section, 9 is the water spray device, 10 is the Venturi outlet section, 11 is the fluidized bed tertiary desulfurization section, and 12 is the desulfurization flue gas outlet.

[0076] The specific working process is as follows:

[0077] (1) The original flue gas enters from the flue gas inlet (2) from the top of the desulfurization device. At the same time, at the top of the desulfurization device, the desulfurization agent slurry passes through the nozzle of the slurry (lye) spray device (3) to be evenly sprayed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com