Efficient food fermentation equipment

A food fermentation and equipment technology, applied in the field of high-efficiency food fermentation equipment, can solve problems such as low alcohol content of wort, influence on beer production, and reduction of malt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] as attached figure 1 To attach Figure 5 Shown:

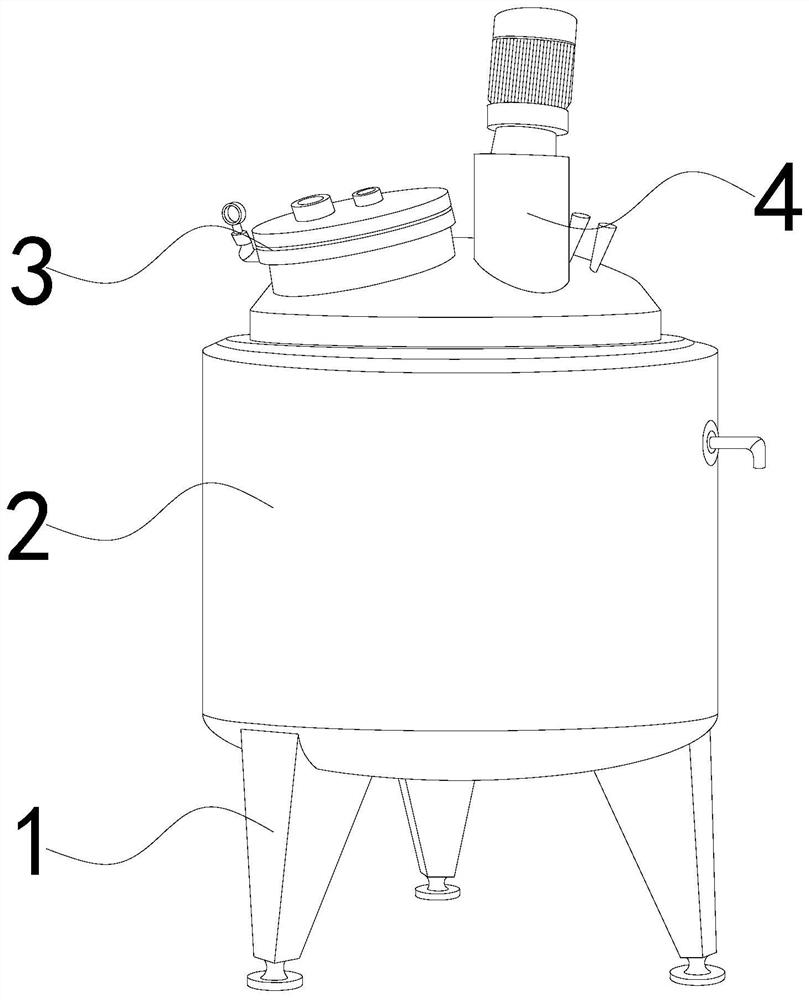

[0026] The invention provides a high-efficiency food fermentation equipment, the structure of which includes a bracket 1, a tank body 2, a top cover 3, and a motor 4, the bracket 1 is welded to the bottom of the tank body 2, and the top cover 3 is movable with the top of the tank body 2 Together, the motor 4 is installed on the top cover 3 top.

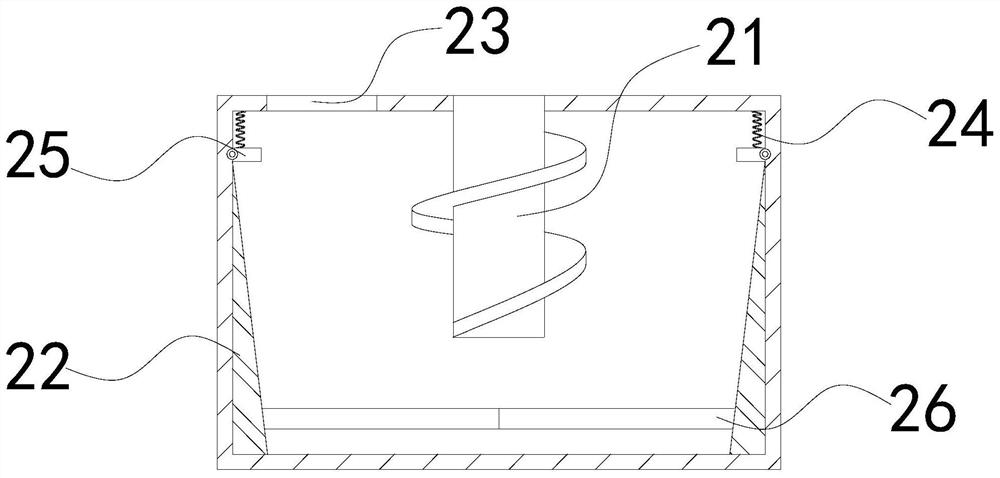

[0027] The tank body 2 is provided with a stirring rod 21, a block 22, an air outlet 23, a spring 24, a support block 25, and a moving ring 26. The stirring rod 21 runs through the center of the top of the tank body 2, and the block 22 is fixed on On both sides of the inner wall of the tank body 2, the air outlet 23 runs through the top center of the tank body 2 to the left, the support block 25 is installed on the inner top of the tank body 2, and the spring 24 is connected between the top of the support block 25 and the inside of the tank body 2 Between the tops, the moving...

Embodiment 2

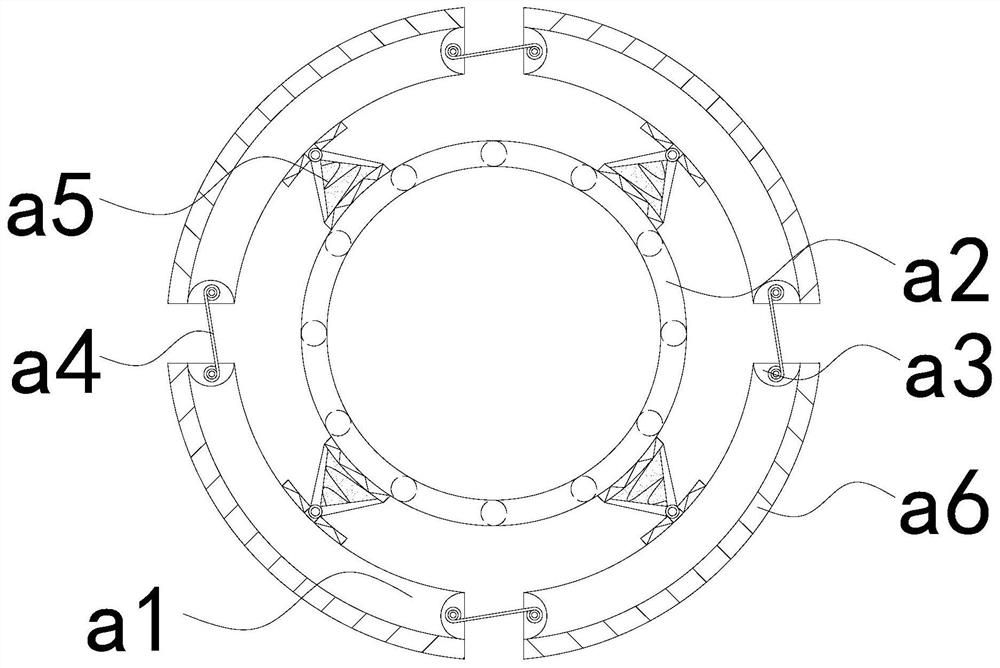

[0034] as attached Figure 6 to attach Figure 7 Shown:

[0035] Wherein, the slider d5 is provided with a top block r1, a card board r2, a slide rail r3, a bottom bar r4, a moving block r5, and a steel block r6, and the top block r1 is nested on the inner top of the slider d5, and the card The plate r2 is set inside the slider d5, and the top is movably matched with the top block r1, the slide rail r3 is set inside the clamping plate r2, the bottom rod r4 is movably matched with the slide rail r3 through the moving block r5, and the steel block r6 is located at the inner bottom of the slider d5 and is located on both sides of the bottom bar r4. The bottom bar r4 is in the shape of an inverted trapezoid, and the straight drop of the trapezoid gradually decreases from top to bottom, which is beneficial to reduce the gap between the bottom bar r4 and the groove d3. Increase the contact area, increase the pressure, and speed up the liquid removal from the surface of the groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com