Novel pumping unit

A pumping unit, a new type of technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of energy waste, low motor load rate, etc., to improve the load situation, improve the balance degree, increase production benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

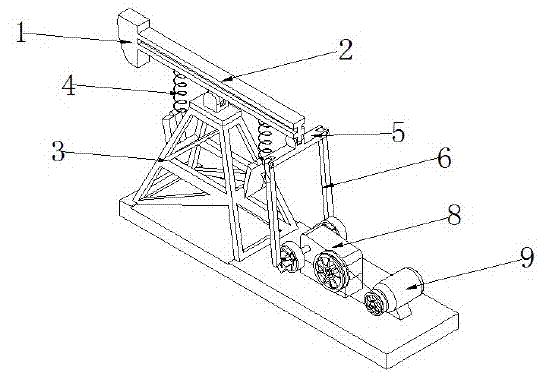

[0012] Below in conjunction with accompanying drawing and example the present invention will be further described:

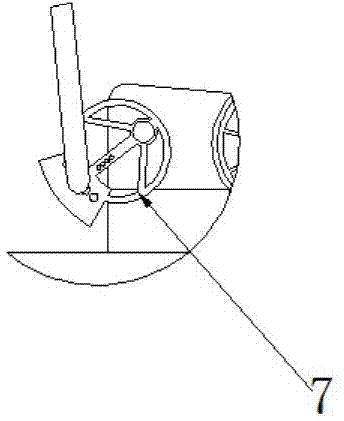

[0013] Such as figure 1 As shown, a new type of pumping unit includes: donkey head 1, traveling beam 2, support 3, high-pressure spring 4, crossbeam 5, connecting rod 6, crank 7, reduction box 8 and motor 9, and described donkey head 1 and traveling beam One end of beam 2 is integrally formed, the middle section of beam 2 is rotationally connected with the top of bracket 3 through a rotating shaft, the other end of beam 2 is rotationally connected with the protrusion in the middle of beam 5 through a rotating shaft, and one end of two high-pressure springs 4 is fixed through a The other end of the two high-pressure springs 4 is fixedly connected to the other end of the beam 2 by means of fixed connection, and the other ends of the two high-pressure springs 4 are respectively connected to the bracket 3 by means of fixed connection. The tops of the two long board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com