Non-pyrotechnic fusing connection separation device

A non-pyrotechnic technology for connecting and separating devices, applied in the aerospace field, can solve the problems of poor safety of the pyrotechnic device, polluted gas or debris, and high quality of the system structure, so as to improve the accuracy of fusing and unlocking, the device carrying capacity is large, and the structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

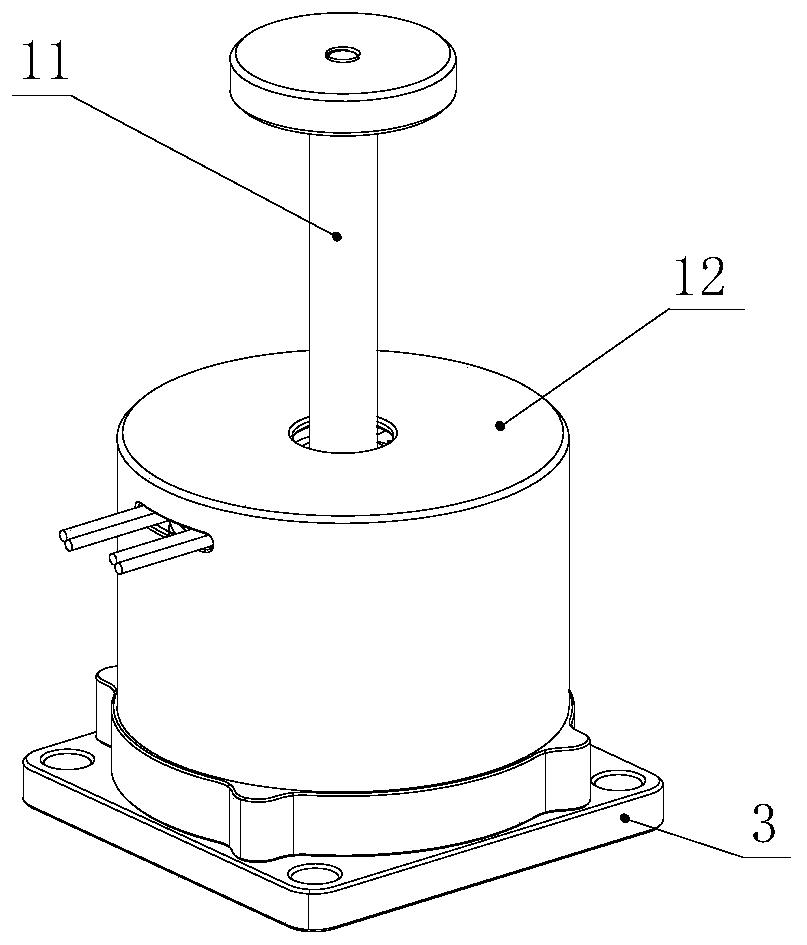

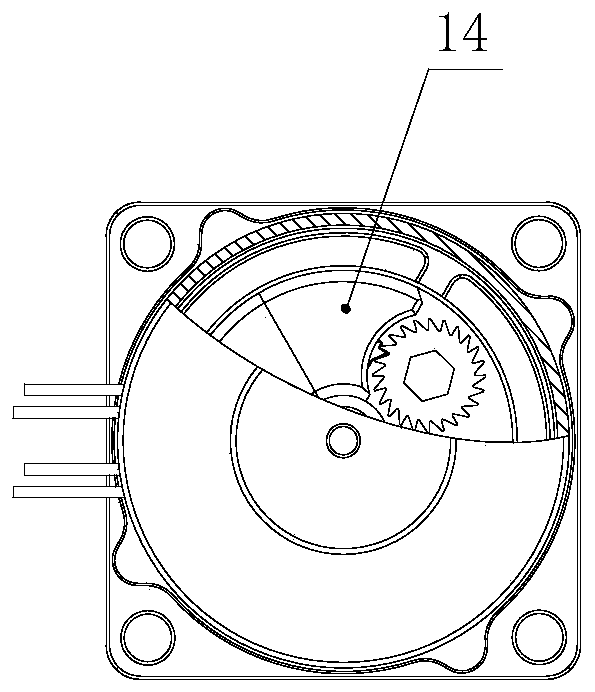

[0045] Such as Figure 1a , Figure 1b combine Figure 3a , Figure 3b , Figure 3c , Figure 6 , is a structural schematic diagram of a new non-pyrotechnic connection and separation device provided by an embodiment of the present invention, including a pressure rod 11, a housing I12, a connection seat 3, a split nut A14, a melting rope 4, a locking torsion spring 5, and a ratchet rope tightening mechanism 6. Insulating briquetting block a7, insulating briquetting block b8, fuse mechanism 9, separation spring 10, split nut A14 is installed on the connection seat 3, and the outer part of the split nut A14 set in the casing I12 is fixedly connected to the connection seat 3, and the casing I The upper surface of the upper surface is provided with a through hole, and one end of the pressure rod 11 is connected to the split nut A14 through the through hole of the shell I12, and the other end of the pressure rod 11 is connected to the base of the separation system. The split nut...

Embodiment 2

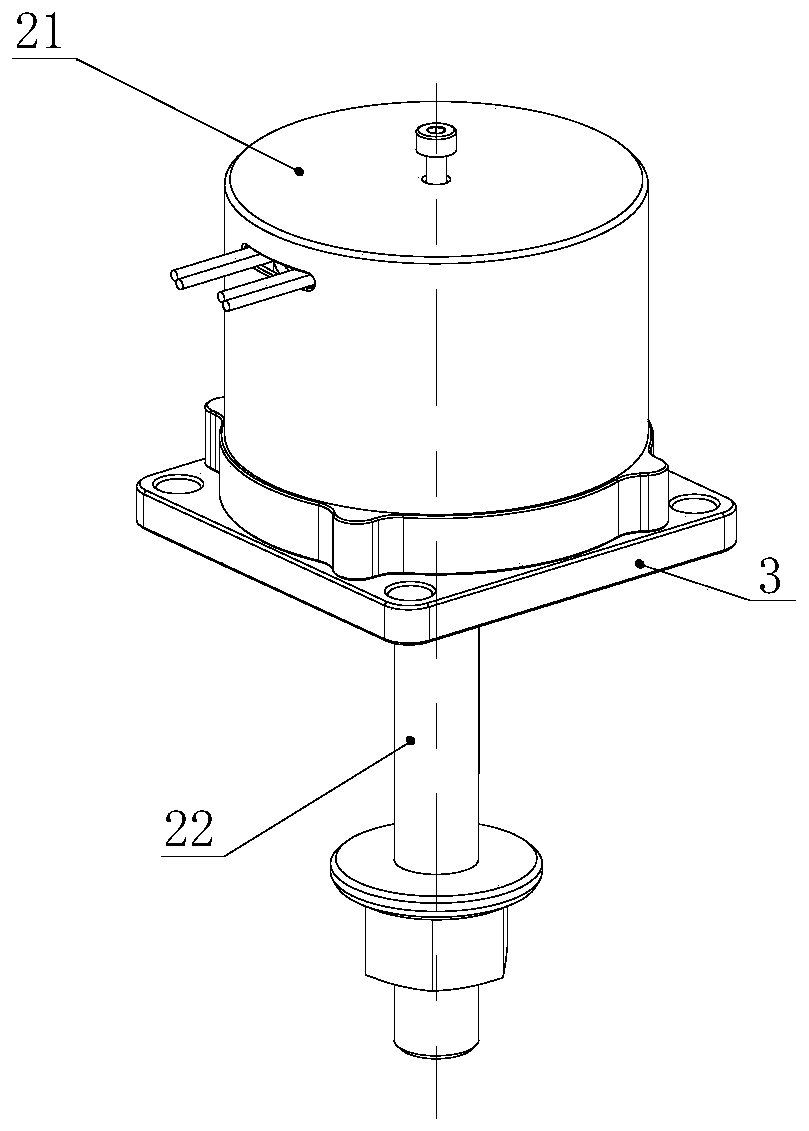

[0051] see Figure 2a , Figure 2b combine Figure 4a~Figure 4d As shown, it is a schematic structural diagram of a new non-pyrotechnic connection and separation device provided by another embodiment of the present invention. In this embodiment, the casing II21, pull rod 22, and split nut B24 are used to replace Figure 1a , Figure 1b Shell I12, pressure rod 11, split nut A14 in the middle, and a conical cap 23, top cap spring 25, anti-off bolt 26 are added, and further, the pull rod 22 passes through the connecting seat 3 to connect with the split nut B24, The rest of the structure remains unchanged. The specific structure is: the split nut B24 is installed on the connecting seat 3, the shell 21 is set on the outside of the split nut B and connected with the connecting seat, the lower surface of the connecting seat is provided with a through hole, and the pull rod 22 One end is connected to the split nut B through the through hole, the other end of the pull rod is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com