Gas stopcock with backlash-free knob construction

A gas cock valve, no gap technology, applied in the direction of the cock including the cut-off device, valve details, valve device, etc., can solve the problems of lack of gear indication function, no mechanical gear switch, etc., to improve the precision And the effect of aesthetics and convenient ignition operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

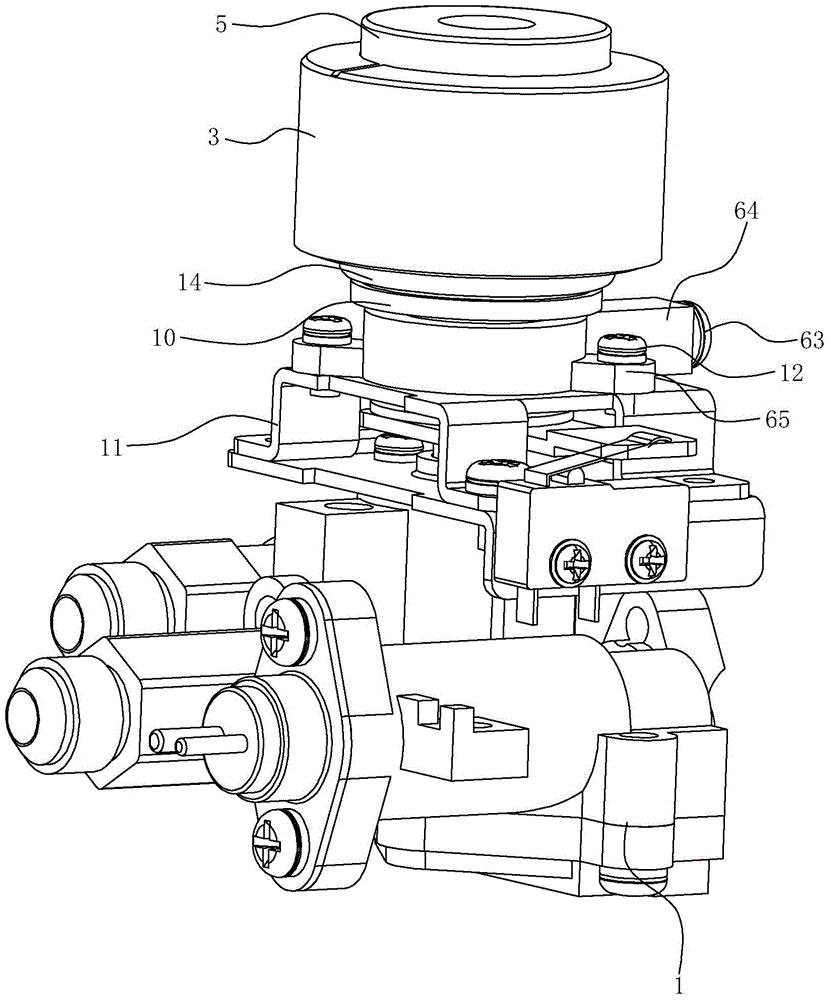

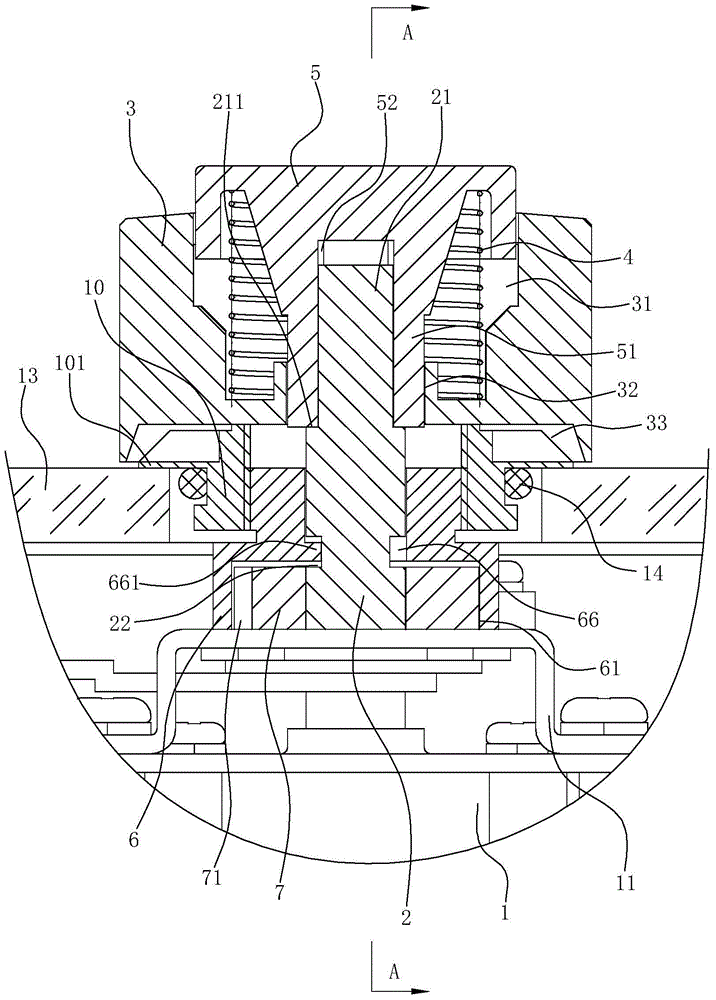

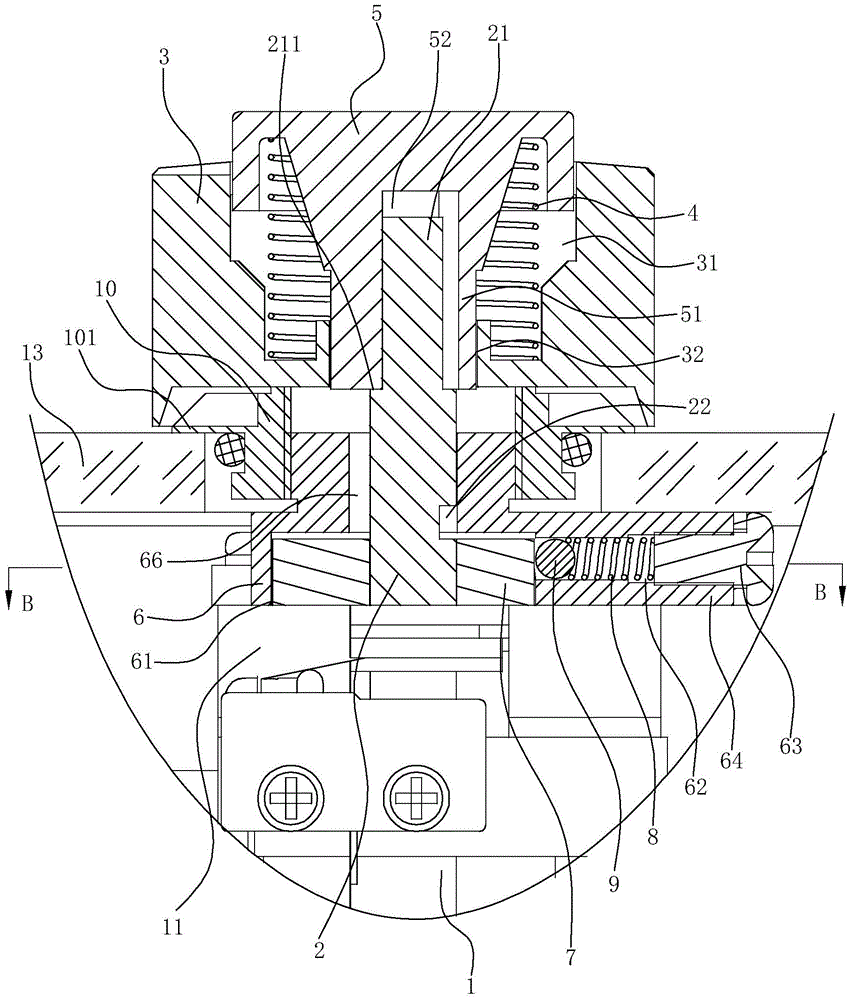

[0034] like Figure 1-14 Shown is a preferred embodiment of the present invention.

[0035]A gas cock valve with a gapless knob structure includes a valve casing 1 and a valve stem 2, and the valve stem 2 is provided with a knob assembly. The knob assembly includes a knob housing 3, a support spring 4 and a knob core 5. The upper end surface of the knob housing 3 has a recess 31 for accommodating the knob core 5, and the lower end surface of the knob core 5 has a rod 51 extending downward. The rod part 51 passes through the bottom of the concave part 31 and is set on the upper part of the valve stem 2. The rotation of the knob shell 3 can drive the rotation of the knob core 5, and the rotation of the knob core 5 can drive the rotation of the valve stem 2. At the same time, the knob core 5 can rotate relative to the knob. The shell 3 moves up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com