LED bulb with transparent lampshade

A technology of LED light bulbs and LED lamp beads, which is applied to lampshades, components of lighting devices, lighting devices, etc., can solve the problems of shortened service life of power supply, waste of electric energy, and reduction of brightness of LED lamps, so as to prolong service life and reduce manufacturing costs. Cost, soft light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

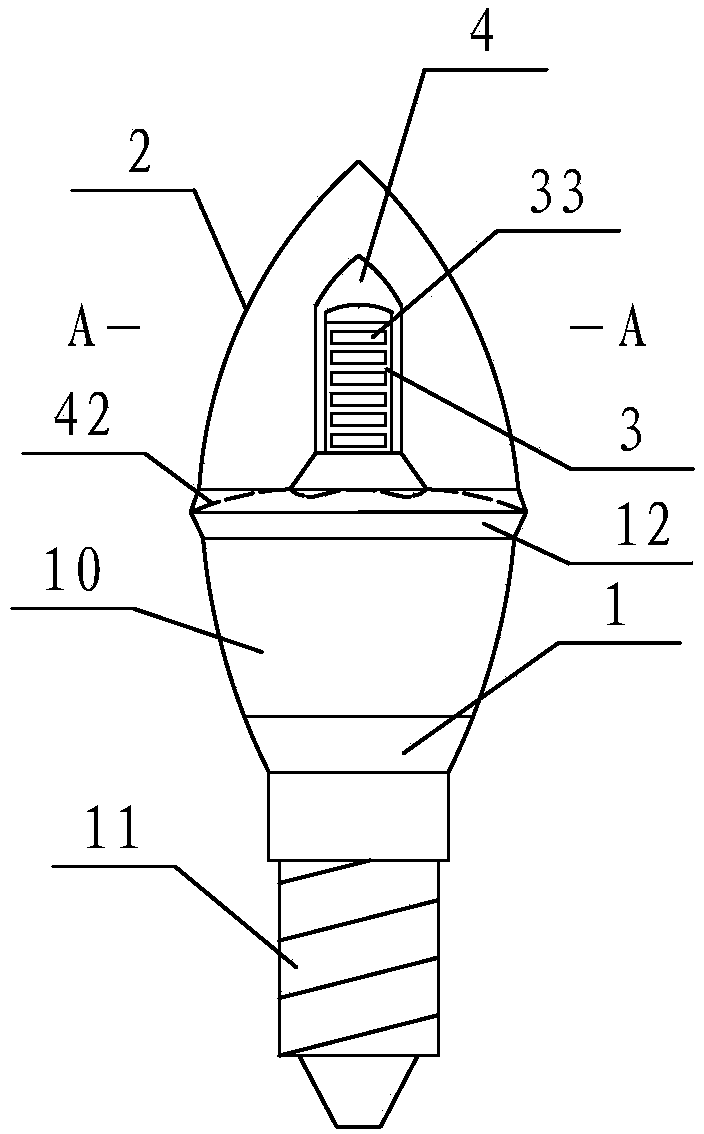

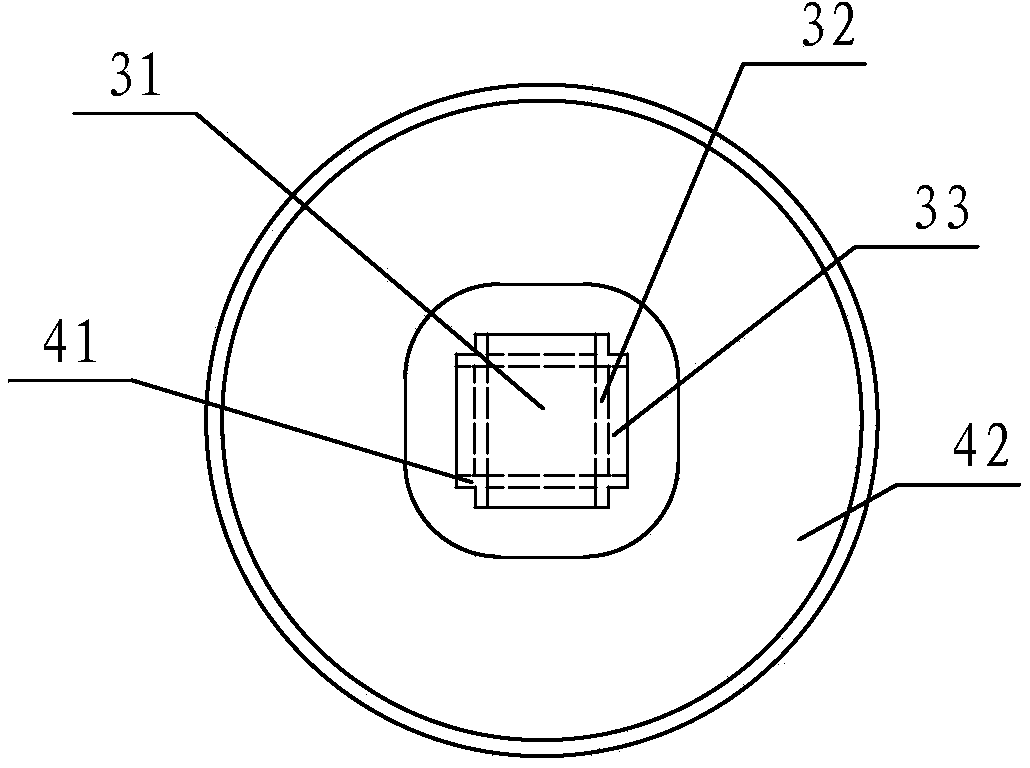

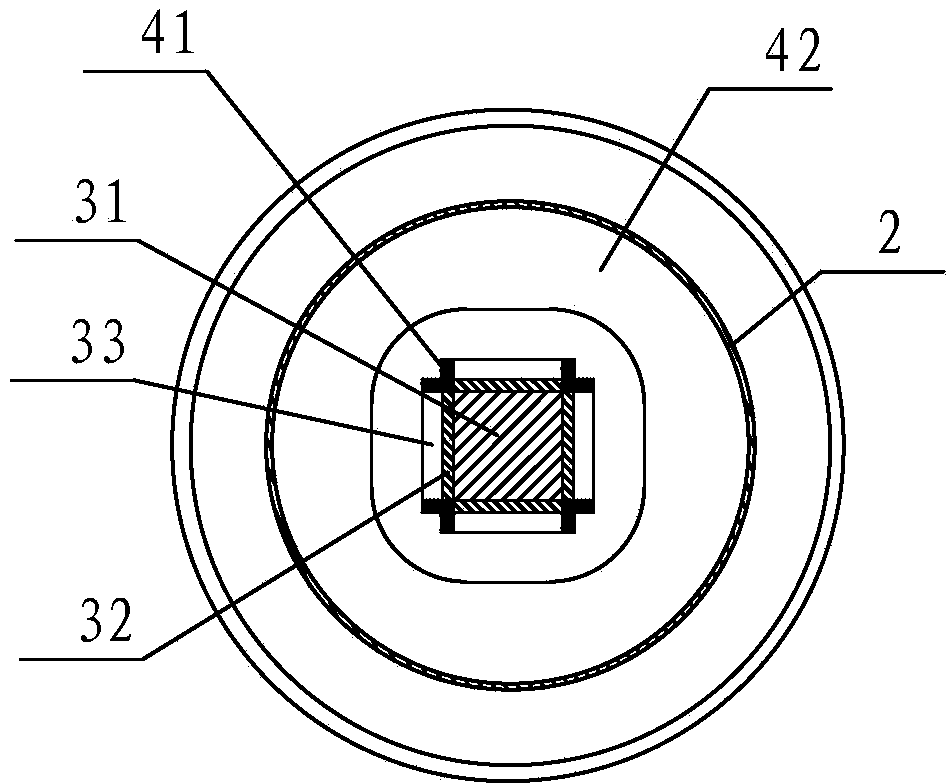

[0015] Such as Figure 1-4 As shown, the LED light bulb includes a lamp body 1 , a transparent lampshade 2 , a light source 3 , a reflector 4 and a power supply (not shown). The light source 3 is a column-shaped light-emitting column, including a heat-conducting column 31 , an aluminum substrate 32 and an LED lamp bead 33 .

[0016] The lamp body 1 includes a connecting portion 10 , a threaded mounting portion 11 , and a light source fixing plate 12 . The connecting part 10 is made of high-temperature-resistant plastic, which is used to connect the threaded mounting part 11 and the light source fixing plate 12 fixed at its two ends, and separate the threaded mounting part 11 from the heat on the light source fixing plate 12 to improve the power supply. operating temperature and improve the service life of the power supply. The thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com