A oil temperature measurement method based on oil pipe surface temperature measurement

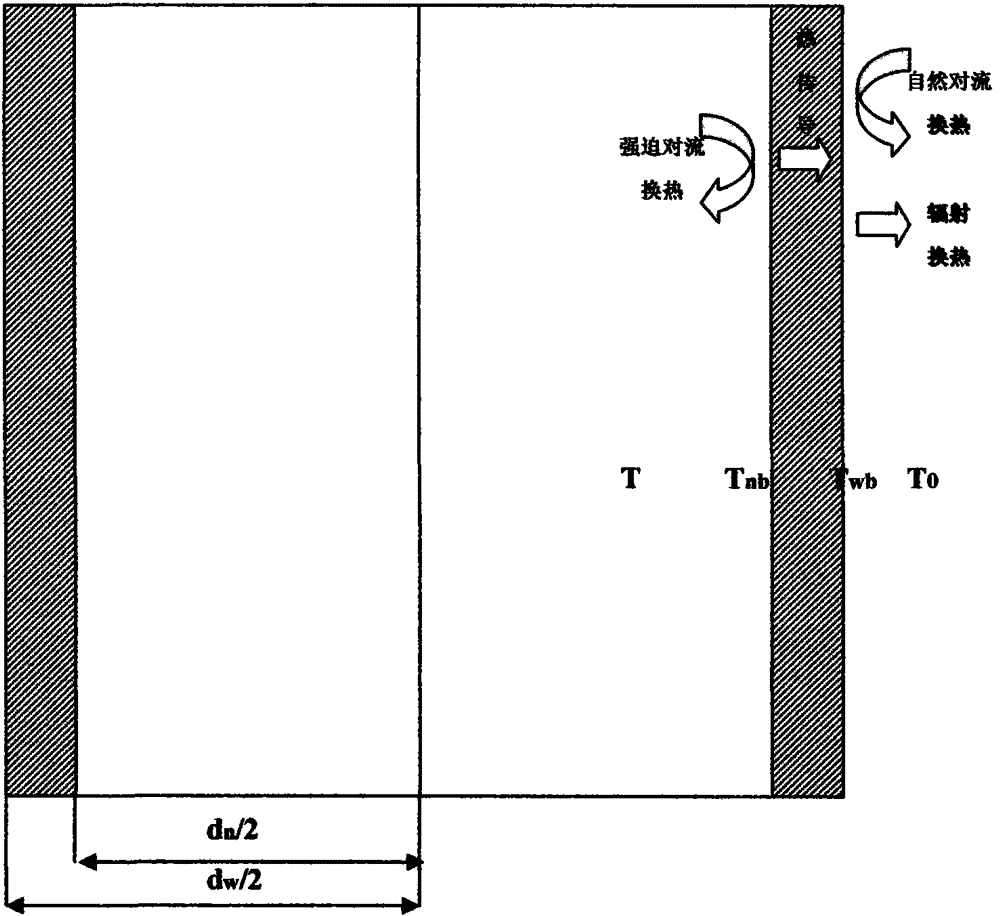

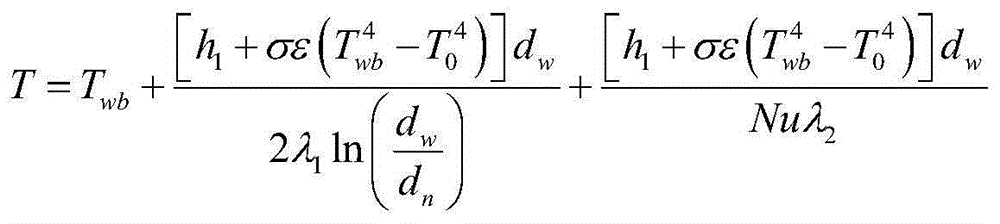

A measurement method and surface temperature technology, applied in the direction of measuring heat, thermometers, measuring devices, etc., can solve the problem of undiscovered hydraulic oil pipes, analysis of radial heat transfer mechanism of oil in oil pipes and oil temperature calculation models, undiscovered oil temperature Research on models and measurement methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific embodiment of the present invention is described further in conjunction with accompanying drawing now:

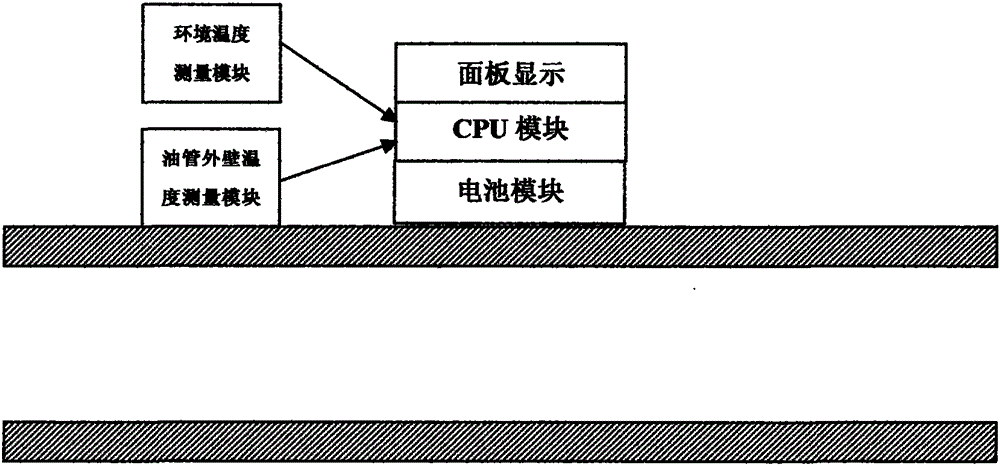

[0057] see figure 1 : the measurement method proposed by the present invention. The oil temperature measuring device includes an oil pipe outer wall temperature measuring module, an ambient temperature measuring module, a panel display, a CPU module and a battery module. Such as figure 1 Shown, method of the present invention comprises the steps:

[0058] Step S1: Install and fasten the oil pipe outer wall temperature measurement module on the outer wall surface of the hydraulic oil pipe by binding, use the oil pipe outer wall temperature measurement module to measure the oil pipe outer wall temperature, and transmit the oil pipe outer wall temperature data to the CPU module.

[0059] Step S2: Expose the ambient temperature measurement module to the air, use the ambient temperature measurement module to measure the ambient temperature, and transmit th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com