Clamping type ultrasonic flow sensor

A flow sensor, ultrasonic technology, applied in the field of ultrasonic measurement, can solve the problems of low measurement accuracy, clamping ultrasonic flow sensor is difficult to clamp, difficult to install, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

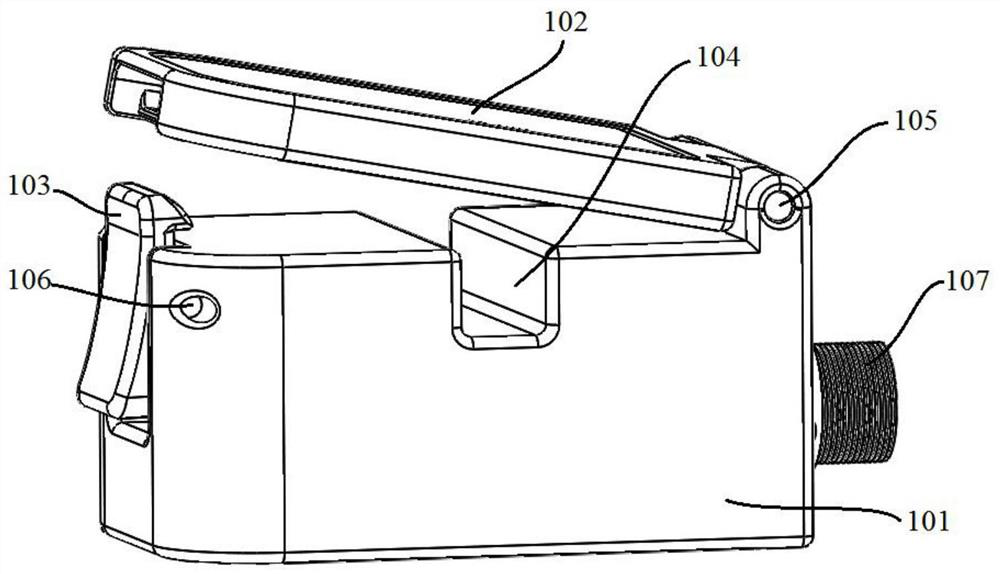

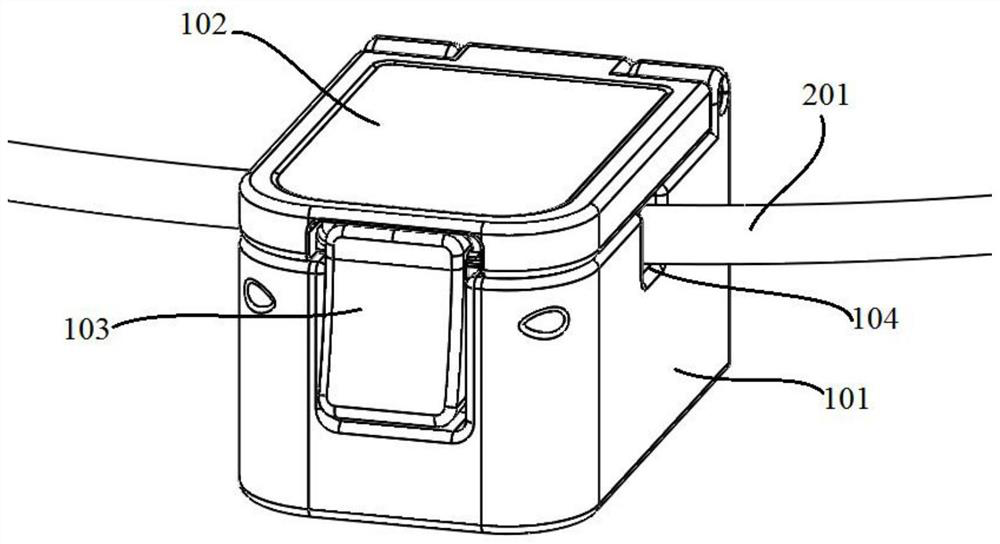

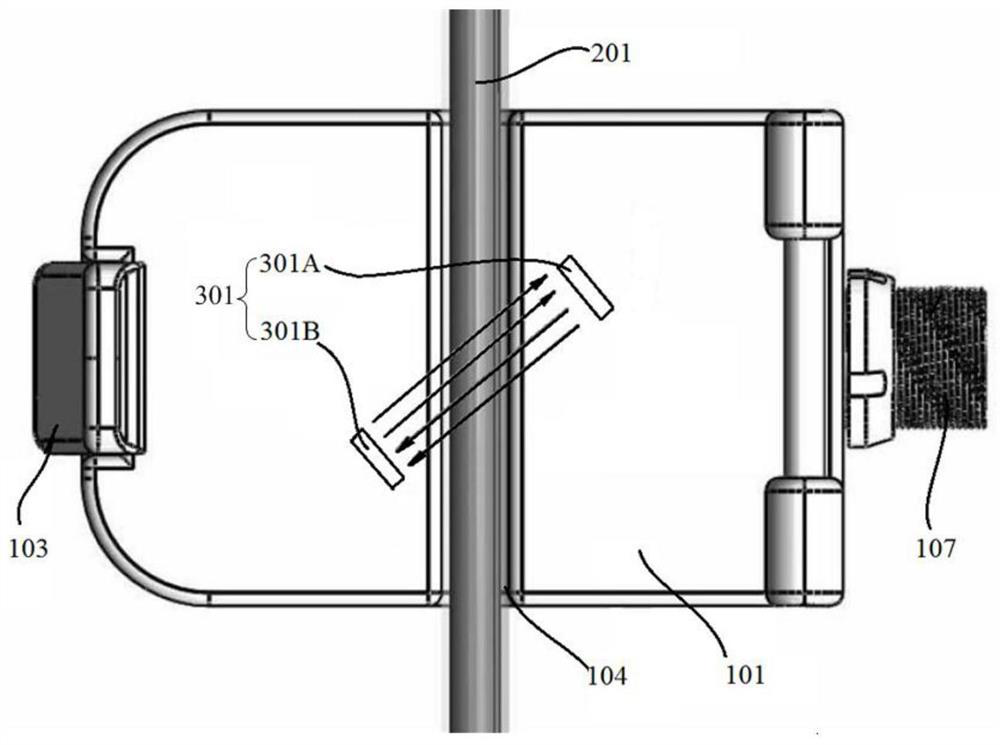

[0033] figure 1 It is a schematic structural diagram of the clip-on ultrasonic flow sensor provided in the first embodiment, figure 2 It is a schematic diagram of the structure of the clip-on ultrasonic flow sensor provided in the first embodiment after the hose is installed. image 3 It is a schematic diagram of the propagation direction of the ultrasonic signal in the clip-on ultrasonic flow sensor provided in the first embodiment, Figure 4 It is a schematic diagram of the installation structure of the ultrasonic transducer in the clip-on ultrasonic flow sensor provided in the first embodiment. This embodiment provides a clamp-type ultrasonic flow sensor, which is suitable for clamping small-diameter hoses, with simple operation, convenient installation, high measurement accuracy and low production cost, which includes: a housing, an upper cover, two Transducer, guided wave structure and ultrasonic flow measurement module.

[0034] Please refer to figure 1 , a groove i...

Embodiment 2

[0048] Figure 5 It is a schematic diagram of the guided wave structure in the clip-on ultrasonic flow sensor provided in the second embodiment, please refer to Figure 5 The difference between the second embodiment and the first embodiment is that the housing 101 of the ultrasonic flow sensor in this embodiment is a hollow structure, specifically, the area corresponding to the two side walls of the measurement channel 104 is not a solid structure. Between the measurement path 104 and the two ultrasonic transducers 301, a waveguide structure 501 is respectively arranged, the waveguide structure 501 is a solid structure, the waveguide structure 501 is a quadrilateral, and any side of the quadrilateral coincides with the side wall of the measurement path 104 ; The waveguide structure 501 can also be a triangle, and any side of the triangle coincides with the side wall of the measurement channel 104 . In this embodiment, the waveguide structure 501 is a right-angled trapezoid, a...

Embodiment 3

[0051] Figure 6 It is a schematic diagram of the guided wave structure in the clip-on ultrasonic flow sensor provided in Example 3, please refer to Figure 6 The difference between the third embodiment and the second embodiment lies in that the shape of the waveguide structure 501 is different.

[0052]Specifically, the width of the waveguide structure 501 in this embodiment gradually increases along the direction from the measurement passage 104 to the ultrasonic transducer 301, and the waveguide structure 501 is a quadrilateral, and any side of the quadrilateral is in contact with the side wall of the measurement passage 104 coincide. That is, the end of the waveguide structure 501 contacting the measurement channel 104 is narrow, and the end of the waveguide structure 501 contacting the ultrasonic transducer 301 is wide. The energy of pipelines and liquids is stronger, the received ultrasonic signal is stronger, and the signal-to-noise ratio is higher, which further impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com