Realization method of automatic alarm system for semiconductor chip automatic packaging equipment

A packaging equipment, automatic alarm technology, applied in the direction of measuring devices, machine/structural components testing, instruments, etc., can solve the problems of manual search trouble, unable to find fault points, faults and abnormalities, etc., to achieve convenient, accurate and rapid positioning, It is convenient for query and management, and the effect of improving retrieval speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

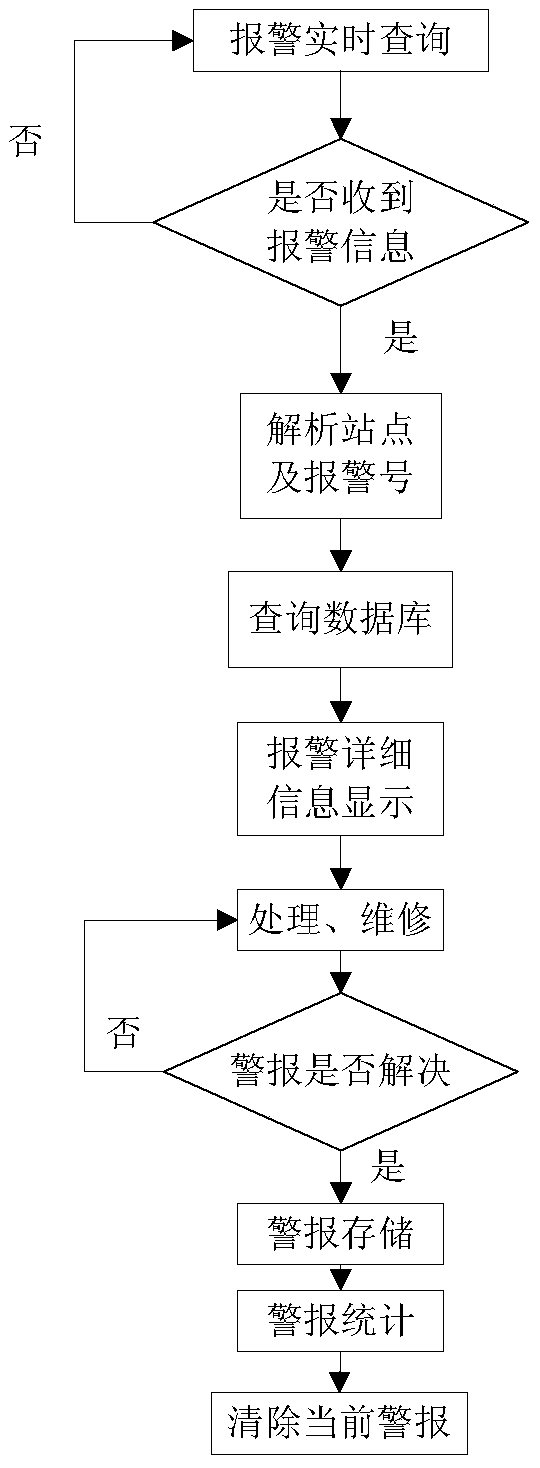

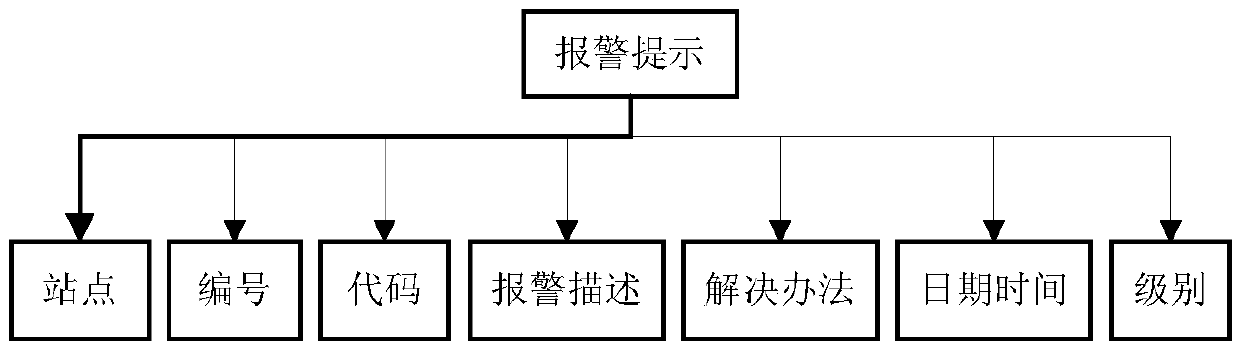

[0026] Such as figure 1 , 2 As shown, a method for realizing an automatic alarm system for a semiconductor chip fully automatic packaging equipment includes the following steps:

[0027] (1) Fault monitoring

[0028] Carry out real-time monitoring of the faults of the semiconductor chip automatic packaging equipment, and find problems in time by cyclically scanning the status of each part of the system in the automatic alarm system control program. The time of each cyclic scanning should be as short as possible to avoid affecting the normal operation of the system, specifically: Divide the fault into several sites according to the fault location, each site corresponds to a relatively independent module of the automatic packaging system, and the system establishes a site fault index; if any abnormality is found during the operation of each site module, it will mark the site fault index of this site; automatically The alarm system program first cyclically scans the fault index...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com