A mechanically connected two-way force creep testing machine

A technology of creep test and mechanical connection, applied in the direction of applying stable shear force to test the strength of materials, etc., can solve the problems of unsustainable force, permanent deformation, and affecting the accuracy of creep measurement, so as to ensure accuracy and weight present effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

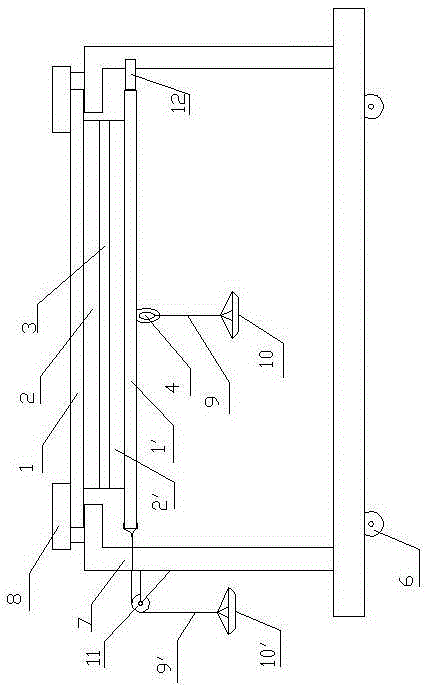

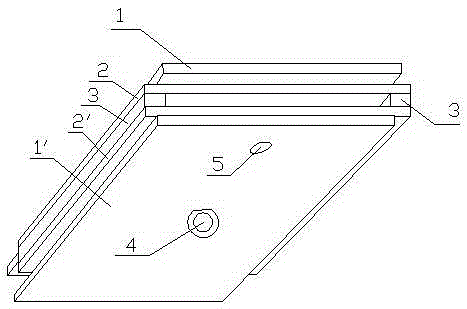

[0018] Such as figure 1 , figure 2 As shown, a mechanically connected two-way force creep testing machine includes a support stand 7 and a test piece, and a lateral loading system and an axial loading system relying on the support stand and the test piece. The support stand 7 is equipped with pulley6. The test piece includes an upper base surface composed of an upper stainless steel plate 1 and an upper glass substrate 2, a lower base surface composed of a lower glass substrate 2' and a lower stainless steel plate 1'; the upper glass substrate 2 and the lower glass substrate 2' are directly bonded by the sealant 3; the center of the front of the lower stainless steel plate 1' is fixed with a hanging ring 4, and the hanging ring 4 is located at the center of the lower stainless steel plate 1' to ensure that the sealant is evenly stressed, and the lower stainless steel plate One end is provided with a hole 5, and the hole 5 is located in the middle of the end of the lower sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com