Dispersion detection method and device for recovering silicon carbide

A detection method and detection device technology, which are applied in the direction of DC flow characteristic measurement, etc., can solve the problems of inability to effectively detect and recover the dispersion of silicon carbide, affecting production and use, and achieve the effect of reducing the risk of mortar agglomeration and improving the cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

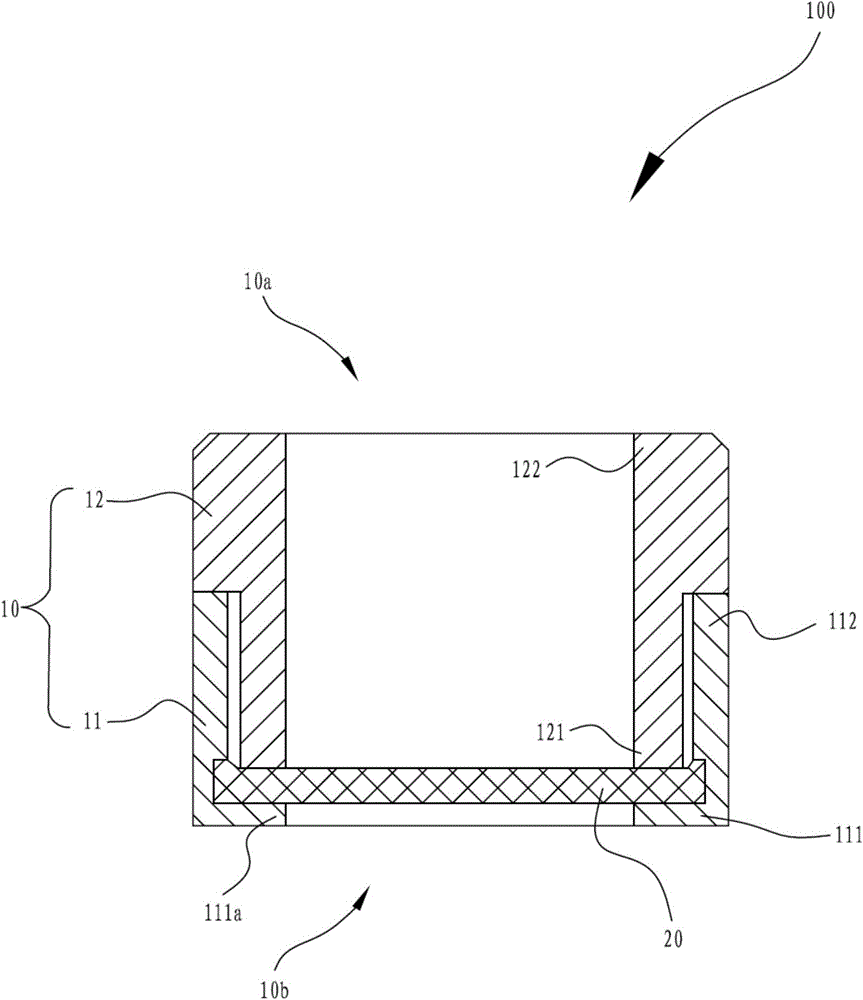

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

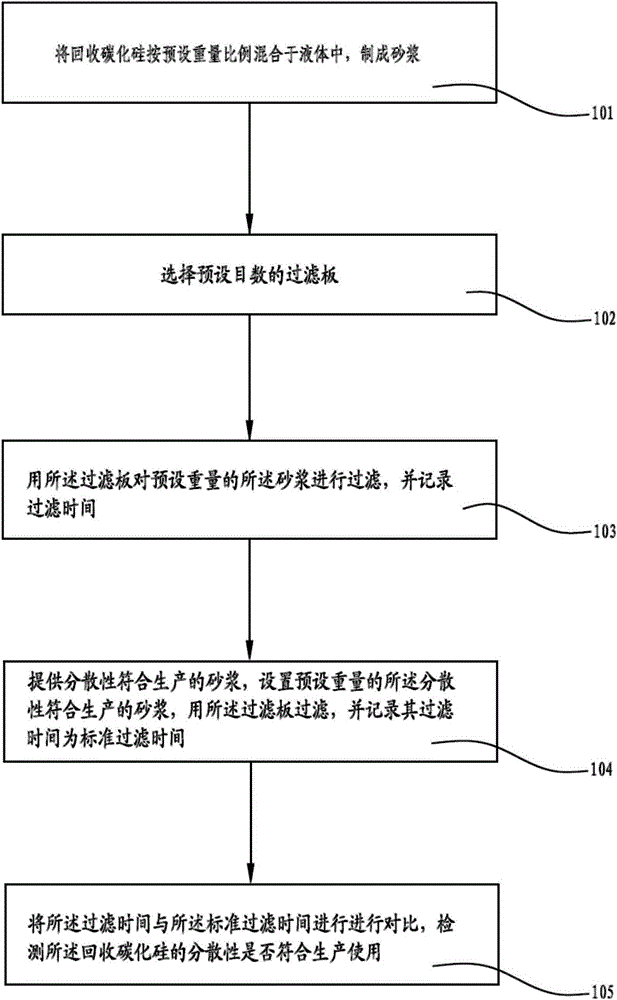

[0024] see figure 1 , a dispersive detection method for recovering silicon carbide provided in an embodiment of the present invention. The method includes the following steps:

[0025] Step 101: Mix the recycled silicon carbide in the liquid according to the preset weight ratio to make mortar.

[0026] Since the recycled silicon carbide is in powder form, it needs to be mixed with liquid to make mortar for easy filtration. In this embodiment, the liquid is PEG-205 polyethylene glycol, of course, in other embodiments, the liquid can also be polyvinyl alcohol. However, the weight ratio of recycled silicon carbide mixed in the liquid determines the consistency of the mortar. When the weight of recycled silicon carbide and liquid is relatively large, the mortar is sticky, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com