Method for producing a separator

A technology for separators and plates, which is applied in the manufacture of final products, electrochemical generators, fuel cell components, etc. It can solve the problems of not optimal physical properties of the final plate, not optimal compression molding, and prolonging the production process, etc. , to achieve the effect of reducing PTFE agglomeration, reducing PTFE content and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

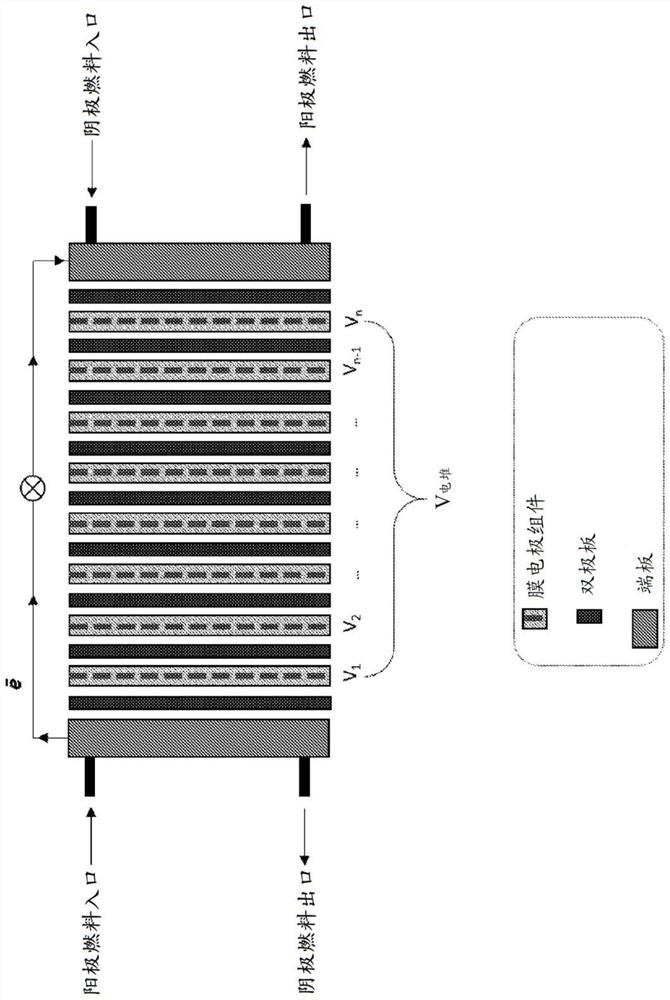

[0043] Bipolar plates (BPP) are one of the key components of fuel cells as they act as separators in a single membrane electrode assembly, connecting them electrically in parallel and providing the voltage required by the stack as V stack =V1+V2+...+Vn-1+Vn, which is also figure 1 shown in .

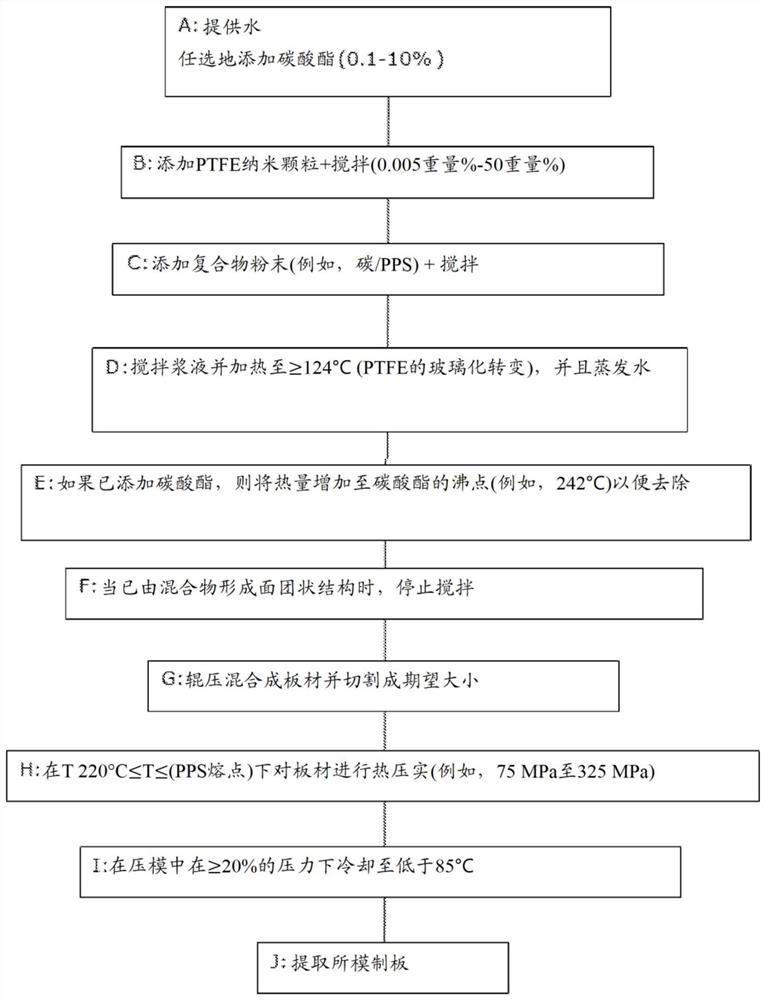

[0044] An example of the production process is given by the following program. The flexible and extensible structure is provided by a fine powder mixture formed into a quasi-elastic mat and then thermally compacted into a separator, especially BPP.

[0045] During production, water is used instead of alcohol, especially isopropanol, to disperse the powder particles. The procedures described herein do not contain alcohol, especially isopropanol.

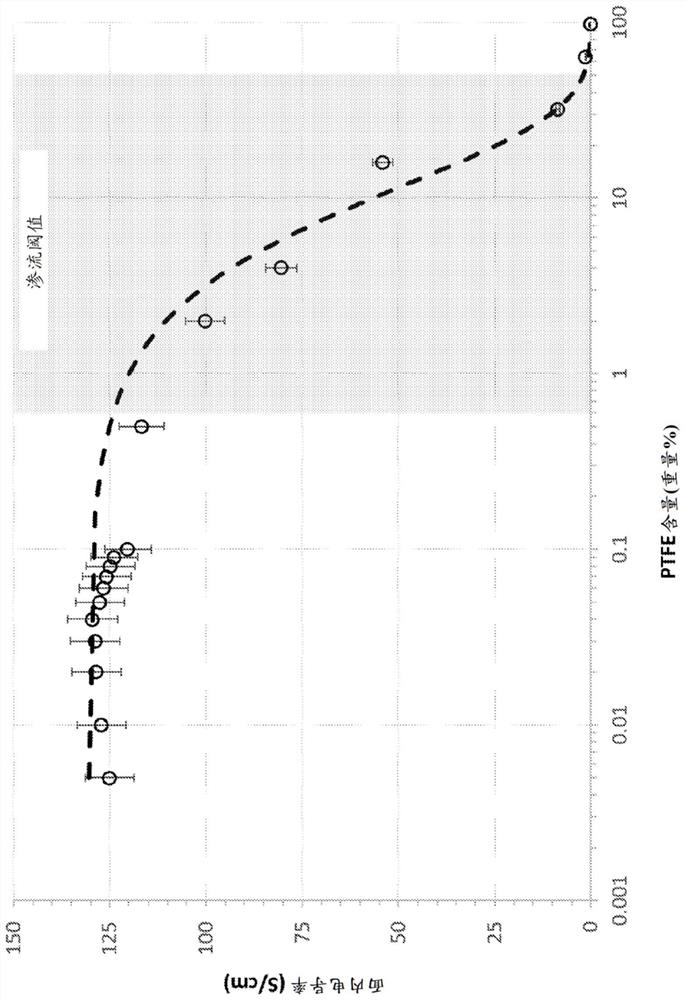

[0046] Although, as stated above, PTFE is a useful ingredient for bonding, its amount should be less than 50% by weight (wt%), and when used for conductive separators, should be less than 10wt%, as follows Explanation.

[0047] figure 2 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com