Slurry dispersion system, negative electrode slurry and lithium ion battery

A technology of dispersion system and negative electrode slurry, which is applied in the direction of negative electrode, battery electrode, secondary battery, etc., can solve the deterioration of electrical conductivity, uneven dispersion of negative electrode slurry, negative electrode slurry blocking filter element and coating particle scratches, etc. problem, to improve the kinetic properties, reduce the risk of agglomeration, and shorten the dispersion time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The slurry dispersion system of the first aspect, the negative electrode slurry of the second aspect and the lithium ion battery of the third aspect of the present invention will be described in detail below.

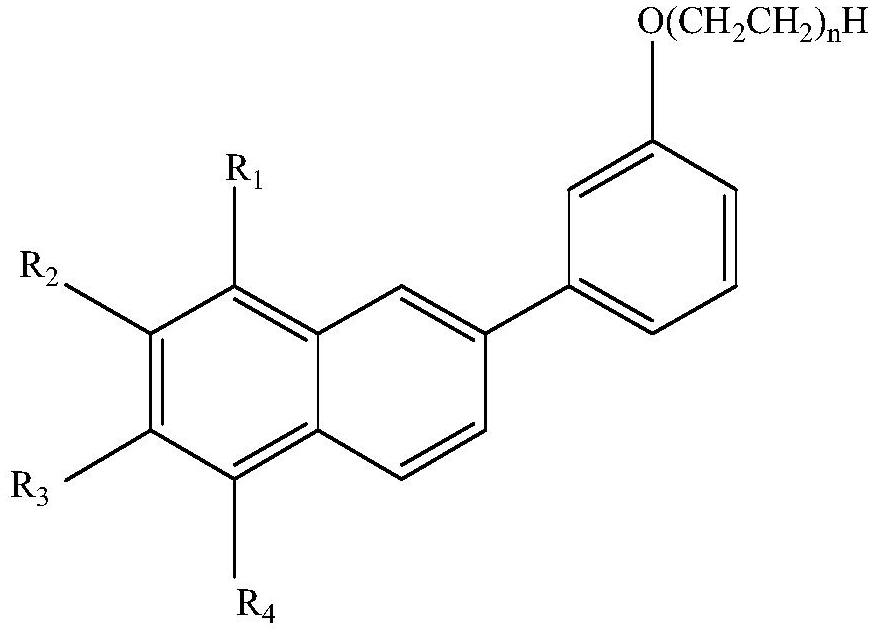

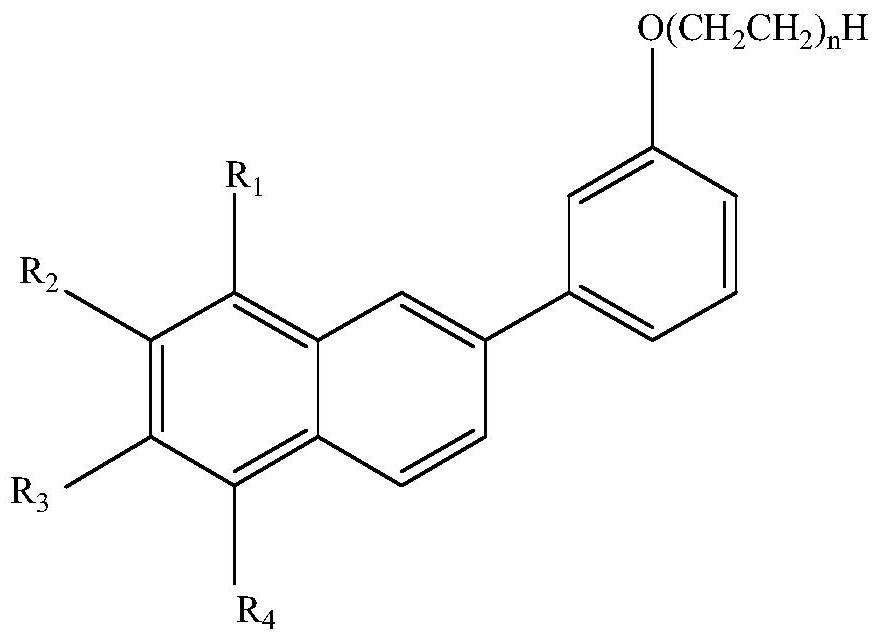

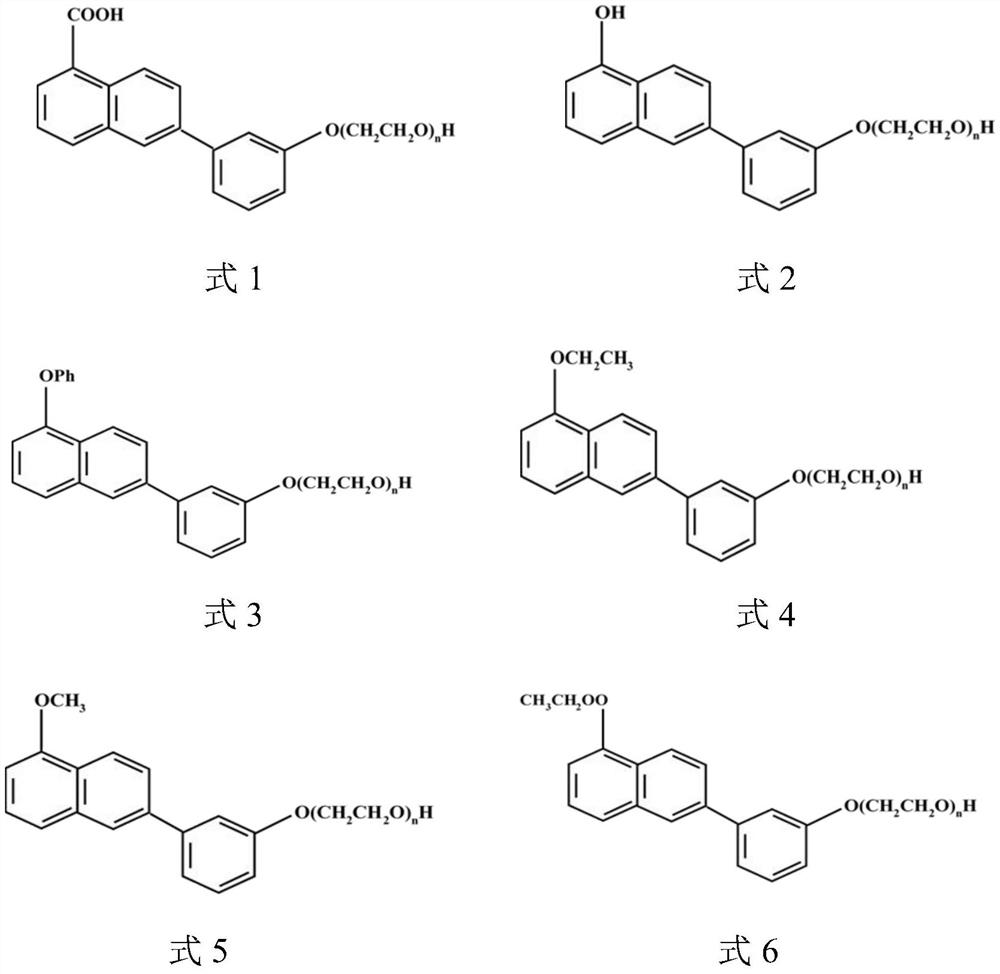

[0012] First, the slurry dispersion system of the first aspect of the present invention is described. The slurry dispersion system includes: a conductive agent, a solvent and an additive, wherein the additive contains an aromatic ring, and the number of rings contained in the aromatic ring is 1-3 indivual.

[0013] To avoid uneven dispersion of the negative electrode slurry and agglomeration of the conductive agent powder, the additives in the slurry dispersion system should be able to fully infiltrate the conductive agent and the solvent, and be able to interact with the active material of the negative electrode slurry through intermolecular interaction. Force and surface binding force to form a stable dispersion system. After a lot of research, the inventor fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com